Available for Medical and Educational institutions.

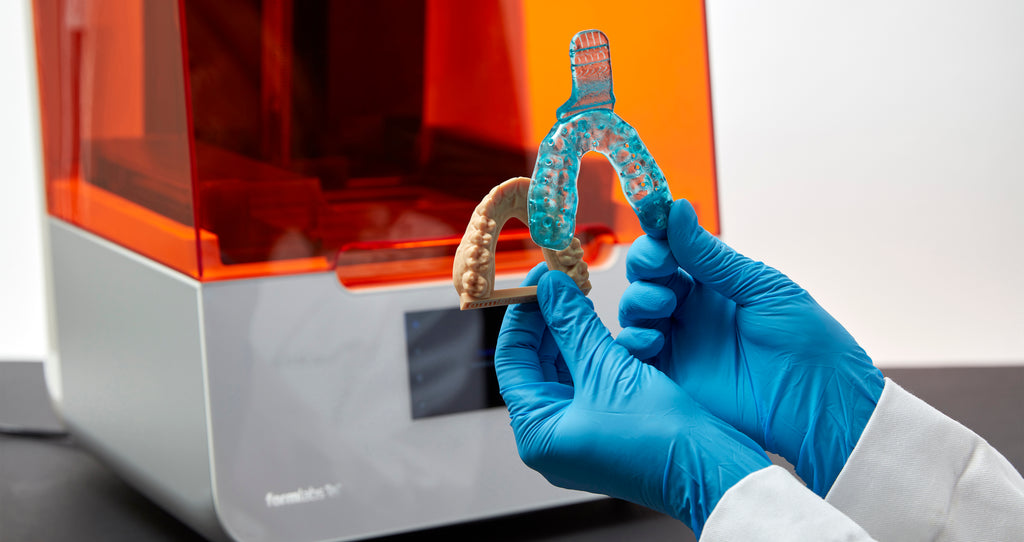

Biocompatible Printing made Easy

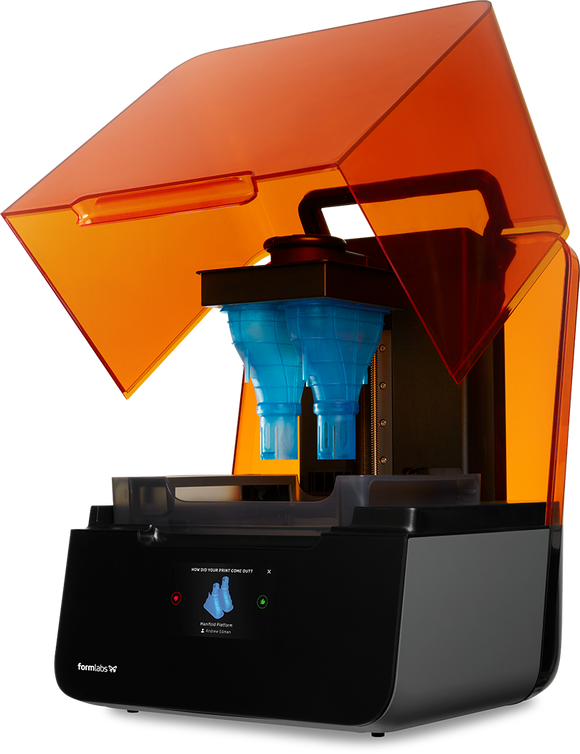

Rapidly print patient-specific parts at the point of care and bring innovative R&D and commercial production in-house with the Form 3B+, an advanced 3D printer for healthcare professionals and medical device engineers. The Form 3B+ is compatible with our entire SLA materials library, including biocompatible, sterilizable materials manufactured in our FDA-registered, ISO 13485 certified facility. The Form 3B+ is simple to set up and maintain; no specialized training is required. From time-sensitive point of care printing to groundbreaking medical device development, work faster and have full control with a versatile, accessible, and scalable 3D printer on-site

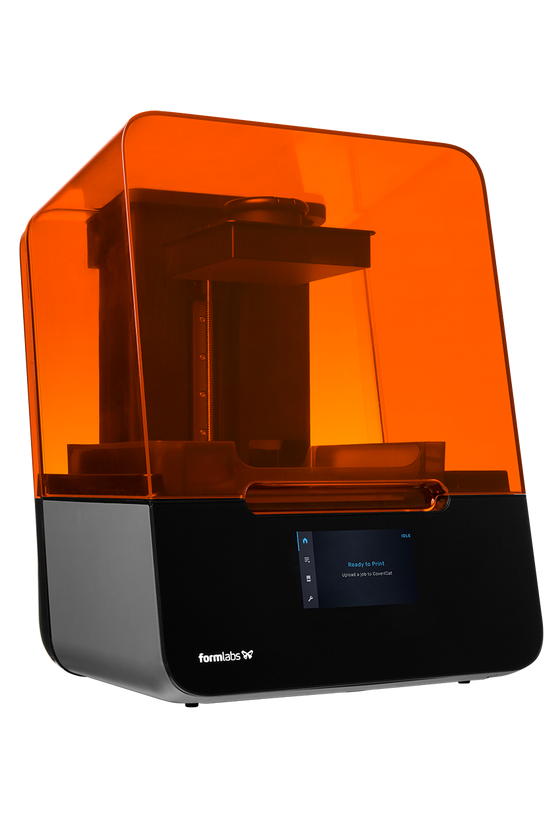

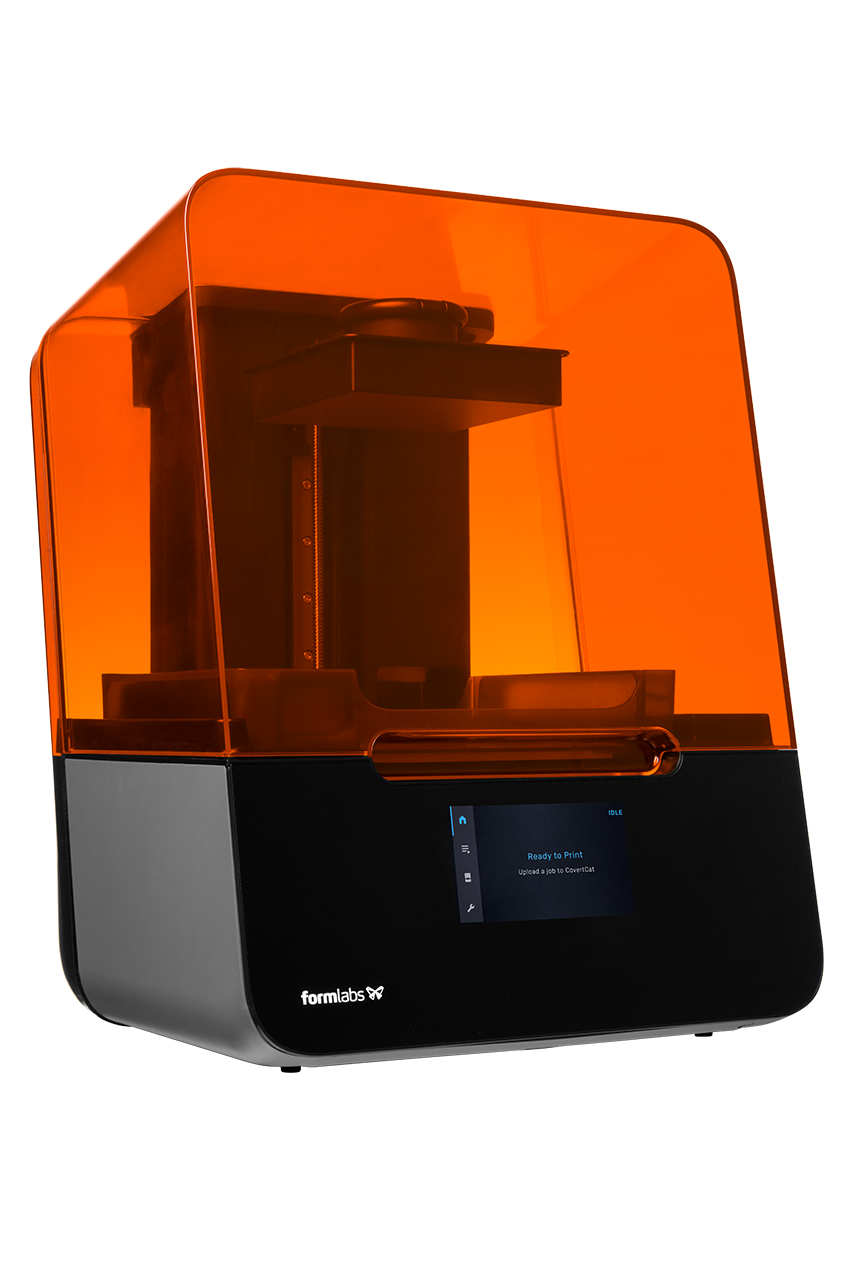

Technical Specs

-

1x Light Processing Unit:

85 micron laser spot size

250 mW laser power

-

Build volume:

14.5 × 14.5 × 18.5 cm

5.7 × 5.7 × 7.3 in

-

Layer thickness:

25 - 300 microns

-

Footprint:

40 x 53 x 78 cm 15.5 x 21 x 30.5 in

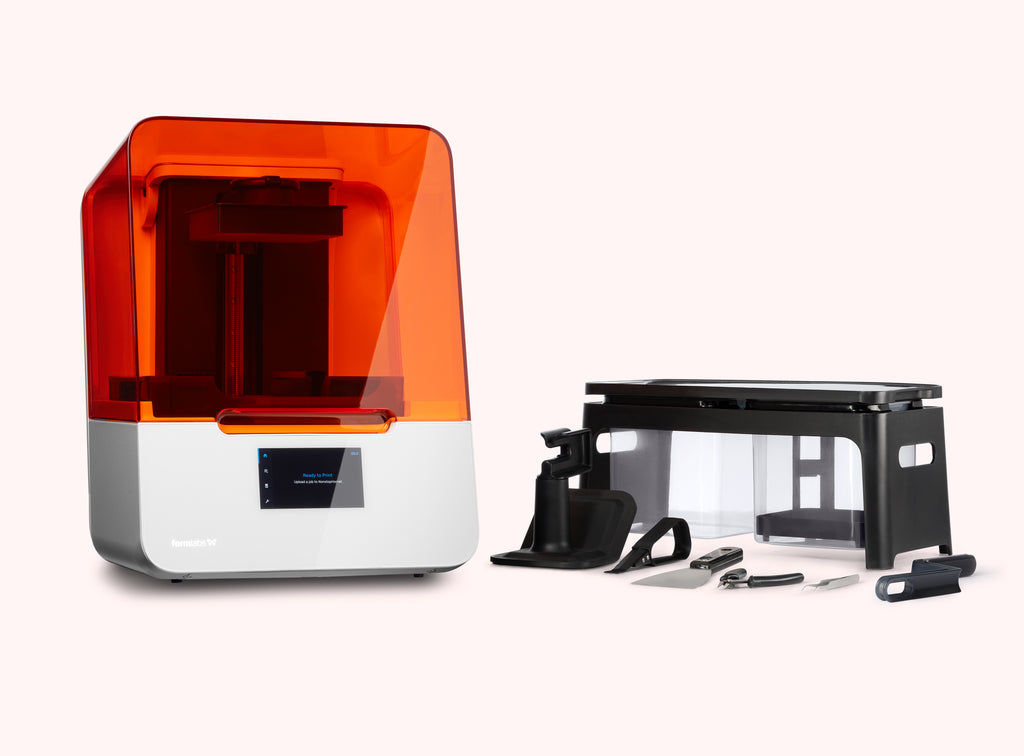

What's Included

- Form 3B+ 3D Printer

- Build Platform

- Form 3 Resin Tank

- Form 3 Finish Kit

- Service Plan of your Choice

Resin sold separately.

Highlights

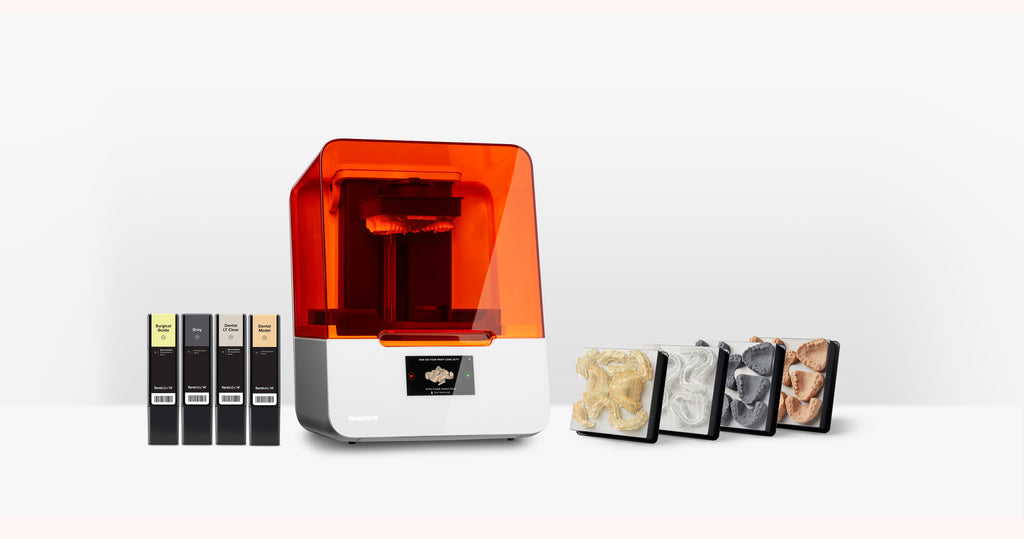

- Usable with Biocompatible Formlabs Resins

- User replaceable Optical module

- Perpendicular laser motion control

- Backward Compatibility with Cartridges, Platforms wash and Cure

- Even Better Print Quality

- Smaller supports required

- Longer tray life

- Advanced Low Force Stereolithography (LFS)™

- Shell Colour is in Silver

Certifications

The Form 3 is CSA Compliant and come with a cUL marking

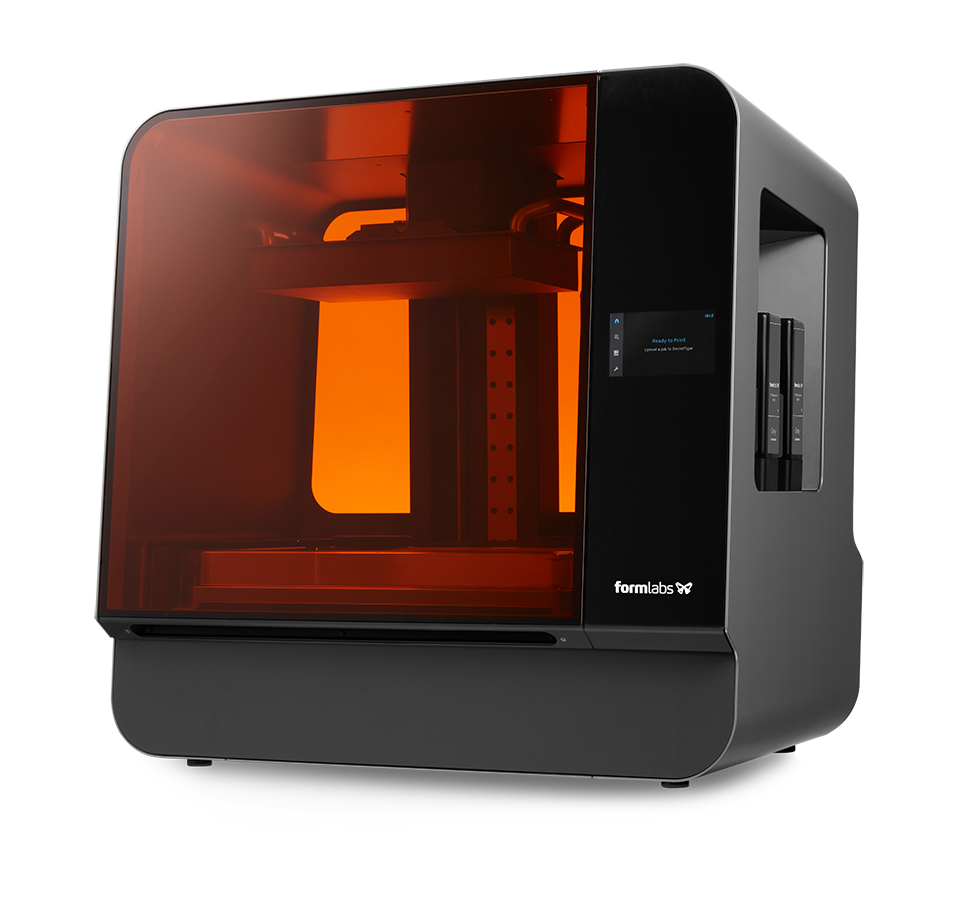

The Easy Choice for Digital Appliance Production

Reclaim your time and produce parts you’ll be proud to deliver, without the hassle or prohibitive costs. Formlabs brings unprecedented reliability, quality, and ease of use, with validated workflows tested by a team of experts.

The Next Generation of 3D Printing - with 25 Micron XY Resolution

Advanced Low Force Stereolithography (LFS)™ technology uses a flexible resin tank and a custom-designed, user-replaceable Light Processing Unit (LPU) to produce consistent, accurate prints. Reduced peel forces lead to incredible surface finish and part clarity, right off the printer.

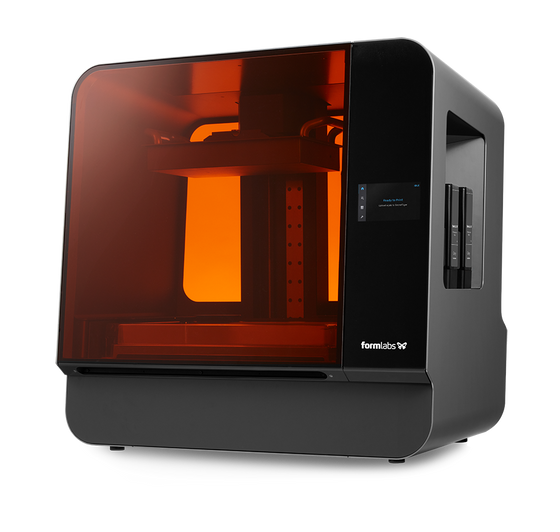

Built for Production - with a 14.5 x 14.5 x 18.5cm Build Volume

Print 2-3 times more parts in a single build compared to small build plate DLP printers to spend less time handling your printer and more time on high-value tasks. Production environments can see 55% less labor time and costs compared to DLP. A modular ecosystem allows for unmatched consistency, scalability, and redundancy.