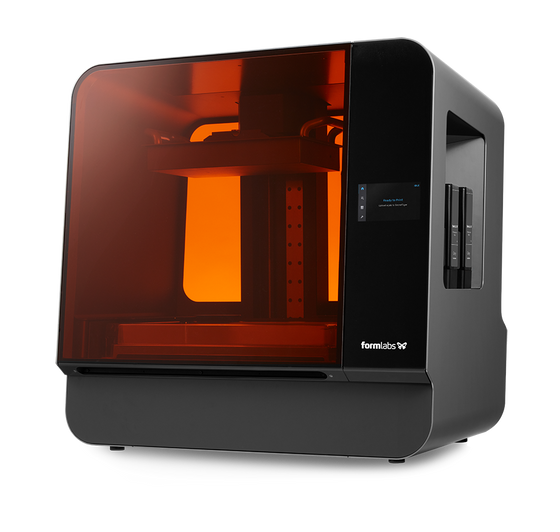

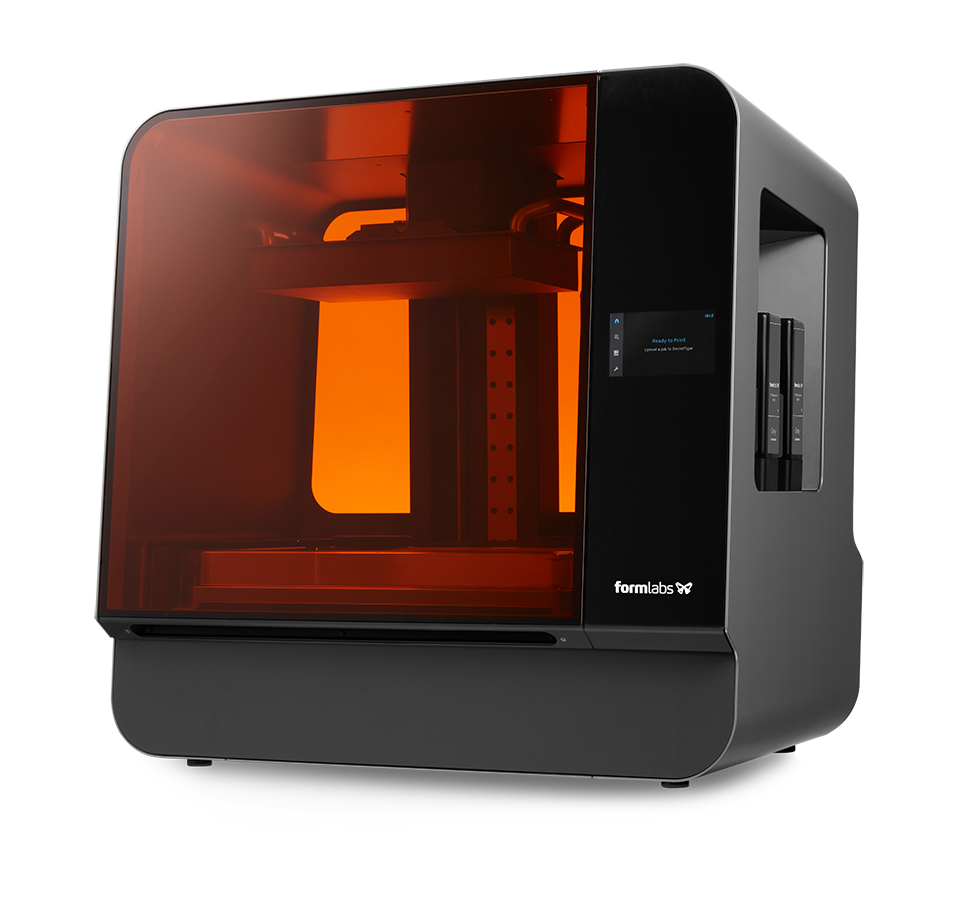

Work faster with the Formlabs Form 3L large-format 3D printer. The Form 3L is versatile enough to bring large scale fabrication in-house. Whether you’re packing the build volume for batch production or printing bulky parts, the Form 3L maintains ideal print conditions for nonstop throughput with minimal supervision. Two precision Light Processing Units (LPU) inside the printer achieve consistent accuracy and detail across the entire build platform. This allows for incredible surface finish and the fine detail that stereolithography 3D printing is known for.

- Technology: Low Force Stereolithography (LFS)™

- XY Resolution: 25 microns

- Laser Spot Size: 85 microns

-

Laser Power: Two 250 mW lasers

-

Build Volume (W x D x H):

33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in) - Layer Thickness: 25 – 300 microns

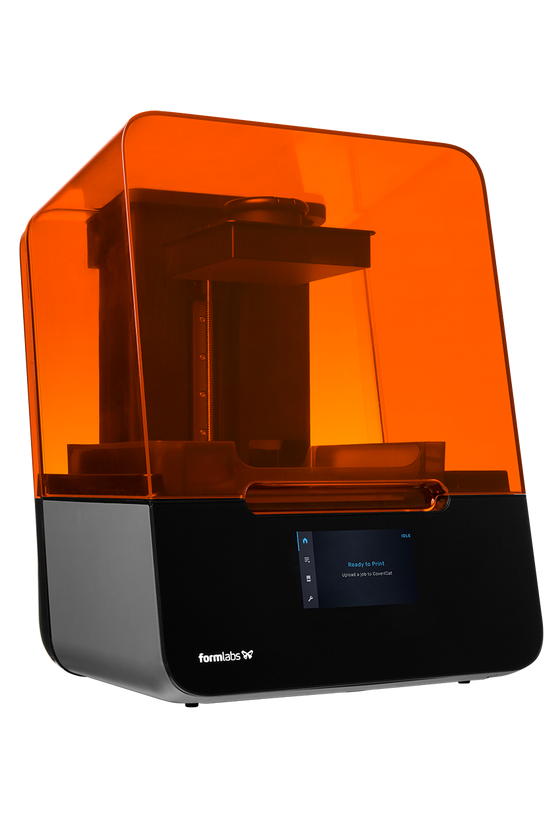

- Form 3L 3D Printer

- Form Cure L

- Form Wash L

- Build Platform Adapter

- Solvent Pump

- Form 3L Build Platform

- Form 3L Resin Tank

- Form 3 Finish Kit (Rinse Bucket and Cleaning Tools)

- 1 Year Extended Warranty (Optional)

Curious to see how you can leverage the Form 3L to fit company needs and get that ROI even faster? Use our tool below to help calculate that.

Form 3L - ROI Calculator

Intuitive and Efficient

No specialized technicians required. The Form 3L offers automatic resin dispensing, simple print preparation software, and a thoughtfully designed interface.

High-Resolution Touchscreen Interface- A 5.5” interactive full-color display minimizes error and eliminates the need for constant monitoring.

- Tested over millions of prints, our free print preparation software, PreForm, automatically suggests optimal orientation, supports, and layout, with the ability to manually refine as needed.

- We believe the best products grow better over time, and we’re committed to continually evolving our hardware through software improvements.

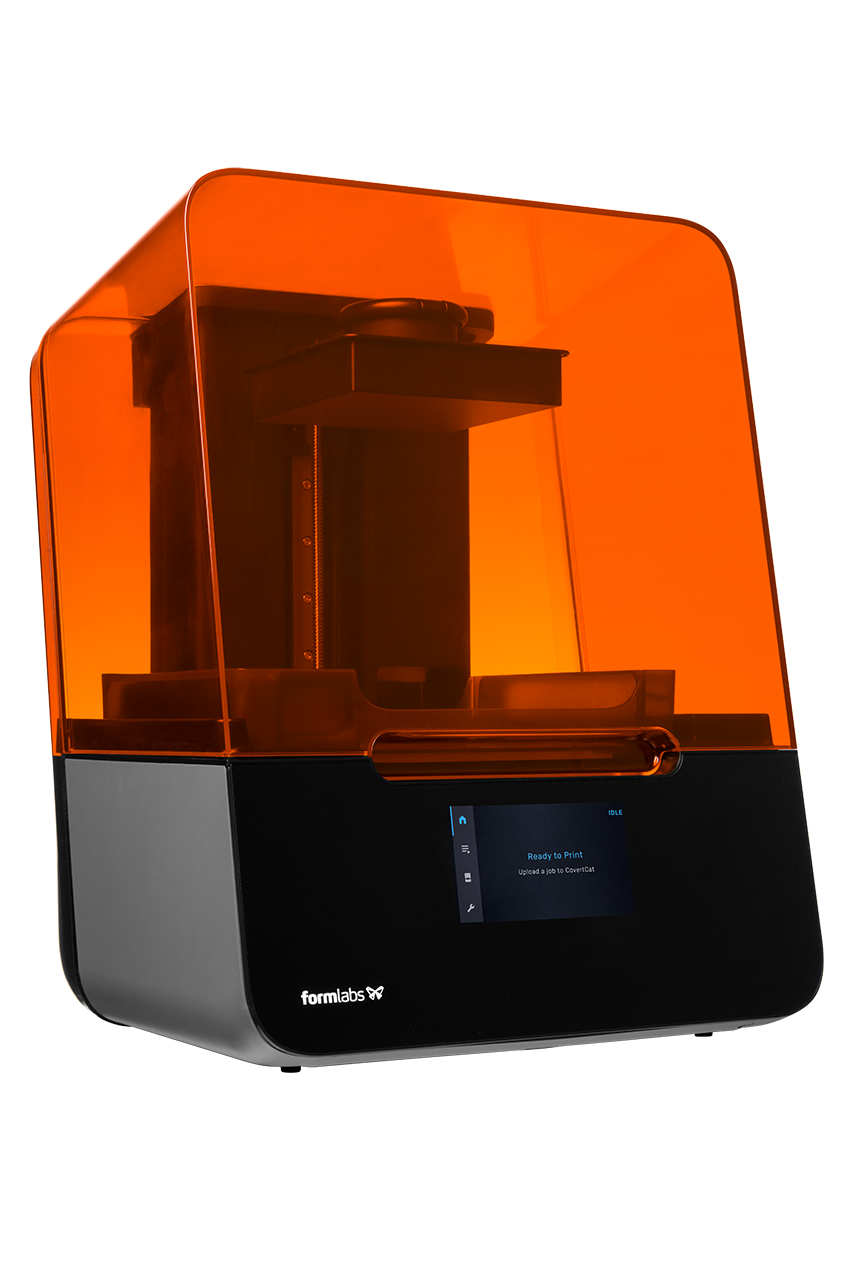

Print Around the Clock

Whether you’re packing the build volume for batch production or printing bulky parts, the Form 3L maintains ideal print conditions for nonstop throughput, with minimal supervision.

Cloud Monitoring- Remotely monitor and manage your fleet of printers with the online Dashboard.

- Draft Resin balances detail and speed to save time on bulky prototypes and enable quick iteration.

- The Light Processing Units, rollers, optics window, and other components can be replaced in-house to ensure 24/7 uptime.

Incredible Part Quality

Stop sacrificing on quality for large-format prints. The Form 3L provides the smooth surface finish and fine detail that stereolithography 3D printing is known for.

Smooth Surface Finish- Models printed on the Form 3L resemble polished injection-molded for realistic looks-like prototyping and consumer-ready end-use part production.

- A system of lasers and mirrors ensures uniform print quality, for an XY resolution of 25 microns across the entire build platform. Leading to clear and smooth prints.

- With precise layer registration and smooth surface finish, translucent materials print clearer than ever, right off the printer

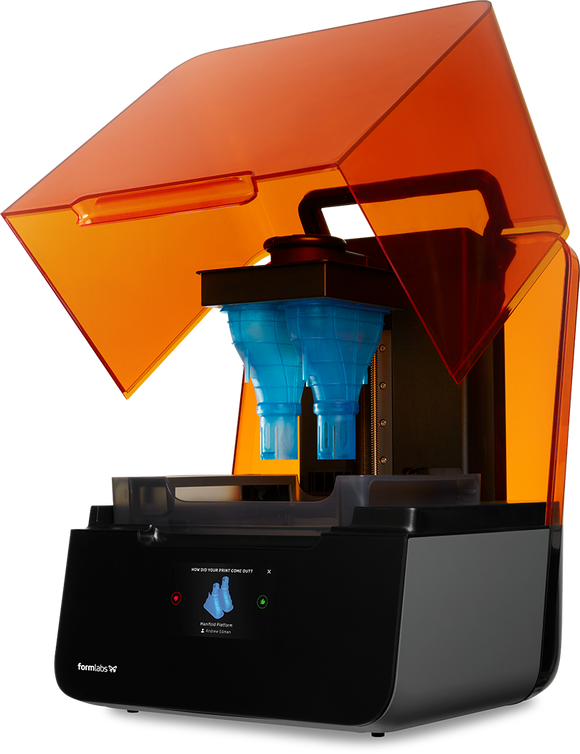

Hassle-Free Materials Management

Choose from a wide range of advanced materials, developed specifically for Formlabs printers by in-house materials scientists. With simplified material switching and automatic resin dispensing, the Form 3L allows you to walk away and focus on other work once your print job starts.

Many Applications, One Printer- Print in over 15 functional resins to support a wide range of workflows on a single platform

- Avoid the hassle and mess of purging materials with our swappable cartridge system, cross-compatible with other Formlabs SLA printers.

- Our automated resin system dispenses resin as parts print. The Form 3L holds two cartridges of resin to avoid mid-print interruptions.

User Replaceable Optical Module

Smart, redesigned optical module allows users to easily replace the core laser module. Reduce downtime, stock backup parts, and allow for future optical module upgrades.

Two Perpendicular Laser Motion Controllers

The Form 3L’s state of the art dual laser system now stays perfectly perpendicular with the build surface ensuring edge to edge consistency at any build volume. Increased spot and overall surface quality.

Low Force Peel

Completely redesigned Peel system reduces peel forces. This allows for more reliable printing of difficult parts, large layers and dramatically improves part quality.

Even Better Print Quality

The Form 3L revolves around part quality, with many laser, peel and support improvements, part quality is more consistent and is even more crisp, beautiful and detailed than ever before.

Smaller Supports Required

Cleanup even easier now with the new low force peel technology. Because of lower forces on the part throughout the print, supports and touch points can be a lot smaller resulting in a much easier post-cleanup process. Less blemishes, less labor, less material used.

Longer Tray Life

Form 3L's Resin tanks now last 20 times longer than standard Form 2 tanks so you can keep churning out parts without worry.

What Resin is this Formlabs printer able to use? and can I use 3rd party resins?

This printer is capable of using all of Formlabs resin from its entire material library, 3rd party materials can not be used on this machine. If you are looking for specific materials message us and we can help find you one!

What is the main defining factor between the Form 3+ and the Form 3L?

The print volume is 5x bigger allowing for greater printing capabilities.

If I have a print failure on the 3L, do I have to remove all the resin and clean out the entire tank?

Formlabs recently implemented a new feature allowing print failure cleanup to be as easy and efficient as possible. The Form 3L has an option to print a “Cleaning Mesh” on the resin tank that binds to cured resin into a single piece that can be discarded from the tank, allowing you to get back to printing quickly.

Why Choose Formlabs SLA

Unparalleled Surface Quality

SLA printing produces the highest quality prints. With parts that come off the machine looking like they’re injection molded. Layer lines are minimal, details incredible. From detailed jewelry casting masters to dental crowns, the Form 3 is unmatched in part quality, detail and cleanliness.

Reliable

With a super high success rate (90%+) You don’t need to worry about failed prints the next day. Run the machine 24/7 on production or prototyping tasks. All can be done on one machine without reconfiguring or calibrating.

Ease of Use

Resins are thoroughly tested by Formlabs and all settings are pre-set and optimized so you don’t need to tweak Any settings. Simply choose your resin, resolution and print. Everything else is taken care of behind the scenes.

Future Proof

With drop-in modules and a constantly evolving library of resins, the Form 3L is the platform in which the future 3D printing will happen. From niche and industry-specific resin like Castable wax and High temp to experimental resins like Ceramic and Colors, you can be sure there will be a steady stream of new developments on the horizon.

Resin Compatibility

Make use of Formlabs’ already impressive resin library from day 1. Over 15 general and niche application resins. From dental, high temperature to castable resins, all with one system.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.