HIGH THROUGHPUT. LOW COST. NO DOWNTIME. - ARRAY from Mosaic Manufacturing

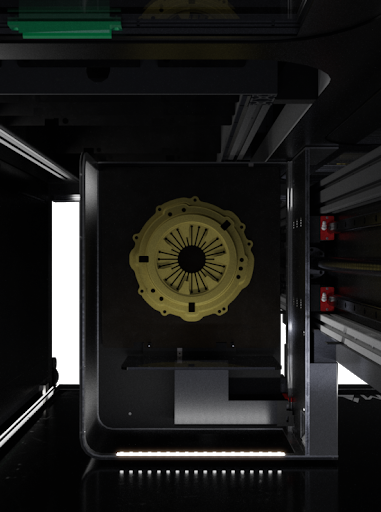

Using Array’s 4 printers and large build volume, smart print queuing, automated print monitoring and modular design, you can now achieve high machine utilization, low downtime and high throughput 3D printing.

Engineered for an automated, easy-to-manage and seamless experience, implementing Array into your production system means you can spend less time on the maintenance and management of your printers, and more time printing - even when you’re not there.

Array's robotic gantry system changes out materials and print beds to ensure your printers are running around the clock.

By increasing your print capacity, Array ensures a lower cost per part, reduces labour, and guarantees a shorter ROI period than other industrial printing systems.

Highlights

AN AUTOMATED MULTI-MATERIAL 3D PRINTING SYSTEM: EXPLAINED

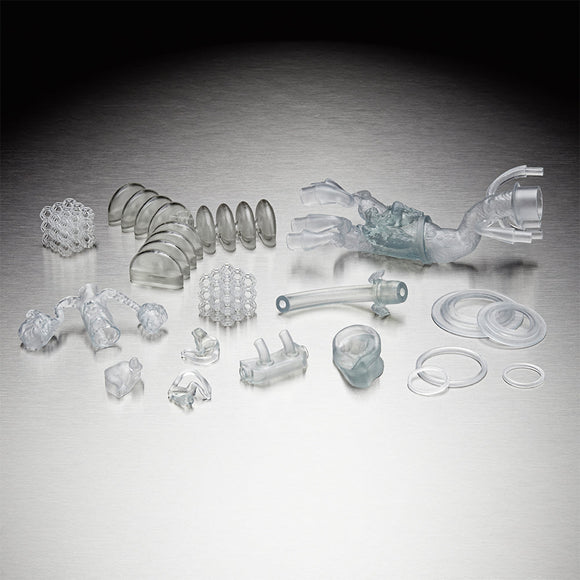

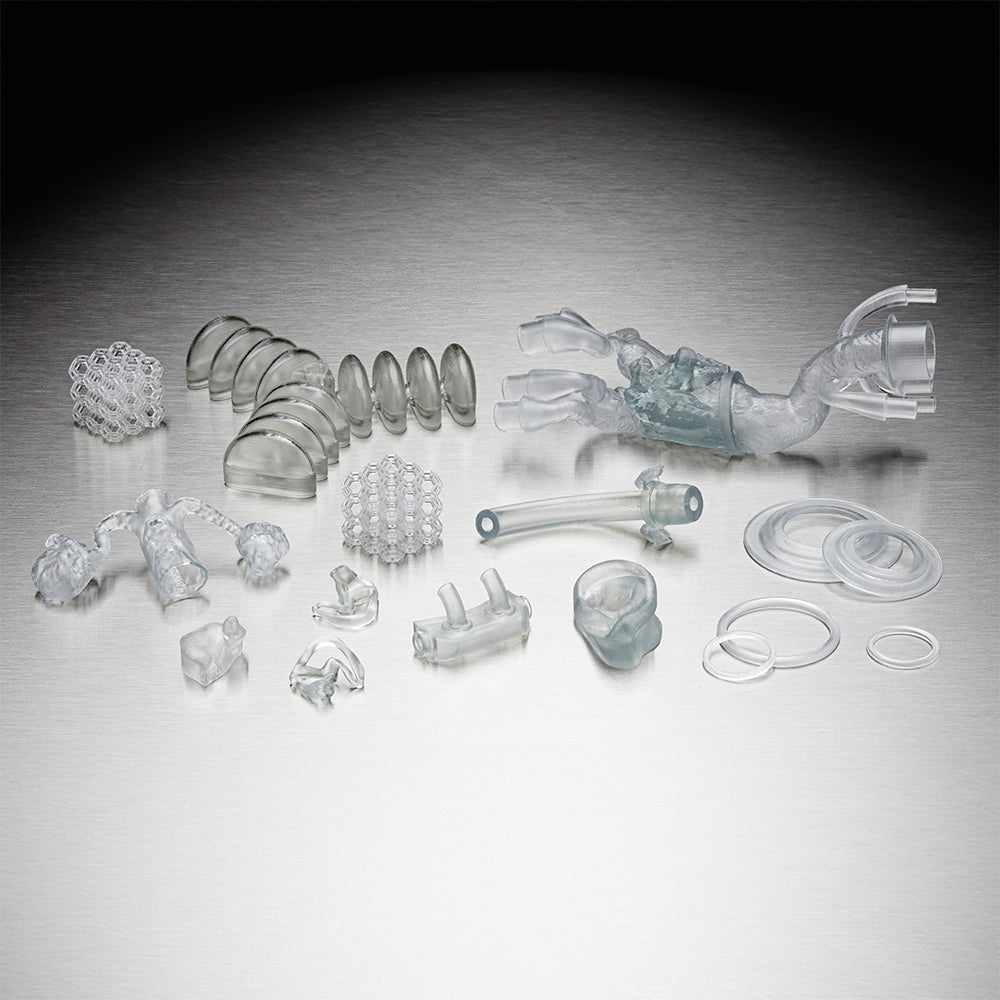

Each printer within Array is outfitted with Mosaic’s Palette X technology and capable of printing models in up to 8 materials and/or colours. The new CANVAS Array slicer software, specifically designed to work with Array, allows you to:

Create a smart print queue, which enables Array to continue printing autonomously for a minimum of 72 hours

Seamlessly manage all of your projects, on your own or with the team

Designate accesses to members of the team (ie. Owner, Administrator, Operator)

Monitor your prints remotely by connecting to webcams within Array

As prints finish, the automated gantry system removes the bed from the printer with the finished part in it, moves it to the storage cart, places a new bed in the printer and CANVAS’ smart queueing then begins the next print. This process continues until your storage cart is filled with finished parts. Once full, an operator replaces the storage cart with a new one containing fresh beds, and Array’s process begins again.

CLOUD CONNECTED TO CANVAS, FREE SINGLE USER LICENSE INCLUDED

CANVAS is Mosaic’s simple and easy-to-use slicer software. CANVAS comes free for a single user and CANVAS TEAMS will be available for those with a larger workforce, allowing effective collaboration.

- Perfect for one material, built for multi-material.

- Set accesses for everyone on the team, from Owners to Contributors.

- Apply color, logos, serial numbers and more directly to your single file 3D models by digitally painting in CANVAS.

- Share, Save, organize, and track your print settings in the cloud for yourself or with the team.

- Monitor your prints from home, or anywhere, using Element’s webcams connected to CANVAS.