The Future of Manufacturing

Unitycoon Co. Ltd successfully improved their turn around time and cut down production costs by using 3D Scanning technology and Raise3D Printers in their workflow. Download the Whitepaper today to find out exactly how they did it!

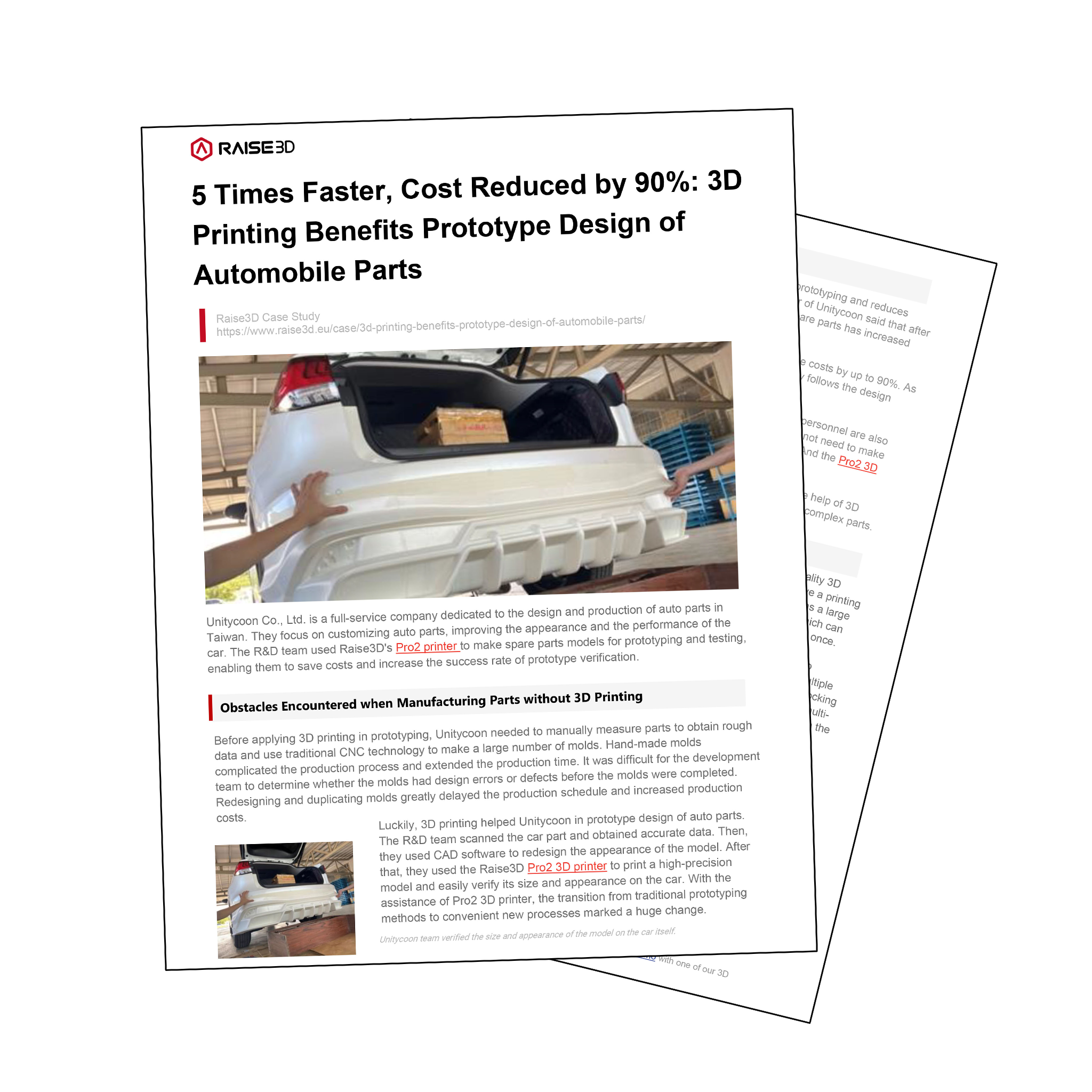

- With just one person, a Raise3D 3D Printer, and some CAD software, you can produce parts faster and more efficiently, reducing production costs by up to 90% and cutting down turnaround time by 83%.

- Create larger parts than other traditional 3D Printers with the Pro3+. Combined with low-cost filament, you can create customised patterns for spoilers, side skirts, bumpers, and other parts for a fraction of the cost.

- Your Raise3D printer paired with the right 3D Scanner is able to produce components that fit properly and have a high level of detail with minimal error and cost.

Have Questions? Shop3D takes pride in the fact that we are always available to assist you.

If you have any questions, please contact us by email or via the chatbot on this page!