More power. More precision. More possibilities.

THE MULTIPLIER

Make fully transparent prototypes, detailed final parts and cast complex objects with flexible molds. Create parts with a high level of detail and accuracy similar to injection molding at a fraction of the cost.

INDUSTRIAL APPLICATIONS MADE POSSIBLE, IN-HOUSE

60 PSI CREATING UP TO 5 TONNES OF FORCE

Create accurate parts with incredible high levels of detail by unlocking more than 4 times the power of vacuum forming.

DELIVER WORKING TEMPERATURES IN MINUTES

Heat materials up to 200 C in under two minutes. The smart levelling system controls pressure during the heating process to keep materials completely horizontal, ensuring consistency of result.

CREATE LARGE PARTS OR MULTIPLE SMALLER ONES

A 400mm circular forming and a vertical allowance of up to 160mm provides you with full flexibility and rapid turnaround times.

HIGH POWER MADE ACCCESSIBLE

Industrial-grade components and smart features deliver a safe and reliable pressure forming process that allows you to focus on the perfect output for your application.

RAPID PROTOTYPING

Pressure forming is the perfect choice for businesses needing to develop a prototype quickly and efficiently, as they can produce it in-house within hours, rather than days.

TOOLING

Create high-quality jigs and fixtures designed to improve assembly quality on the production line with the help of a wide variety of materials. The Multiplier is ideal for creating flexible final parts and molds to cast components with resins.

END-USE PARTS

Go beyond prototyping and create end-use parts with a high level of detail and precision. In addition, our range of materials and thicknesses can cover many applications, including those that require engineering materials.

PACKAGING

Create packaging for both prototypes and final products. Our selection of materials and thicknesses enables you to produce high-quality packaging with a high level of detail quickly, ensuring optimal results.

TECHNICAL SPECS

Machine Dimensions

- Length: 585mm

- Width: 515mm

- Height: 420mm

- Weight: 67.5kg

- Forming Area:400mm (W) x 160mm (H)

- Max template volume: 3500cm3 / 214in3

Technical Data

- Maximum Pressure: 4.1 bar/60psi (Dome), 12 Bar/175 psi (tank)

- Input: 110-240v, 12A/6A (Single Phase)

- Max Power: 1500W

- Frequency Band: 2.4GHz

- Operating / storage temperature: +5 to +40C

- LCD Resolution: 720x720

- Connectivity: WiFi

A SUITE OF INDUSTRIAL-GRADE THERMOFORMING MATERIALS

UHMW 3.0mm

- Low friction coefficient

- High tensile strength

- Abrasion & Chemical resistant

And more launching soon...

If you have questions about material compatibility or other inquiries about the Mayku Multiplier you can contact our team via the form below, and we will get back to you shortly.

MAYKU MULTIPLIER RESOURCES

Check out these resources below from Mayku to learn more about the Multiplier's quirks and features.

Guide: Vacuum forming vs Pressure forming comparison

Discover how both technologies compare to each other, how they work, common materials, benefits and more

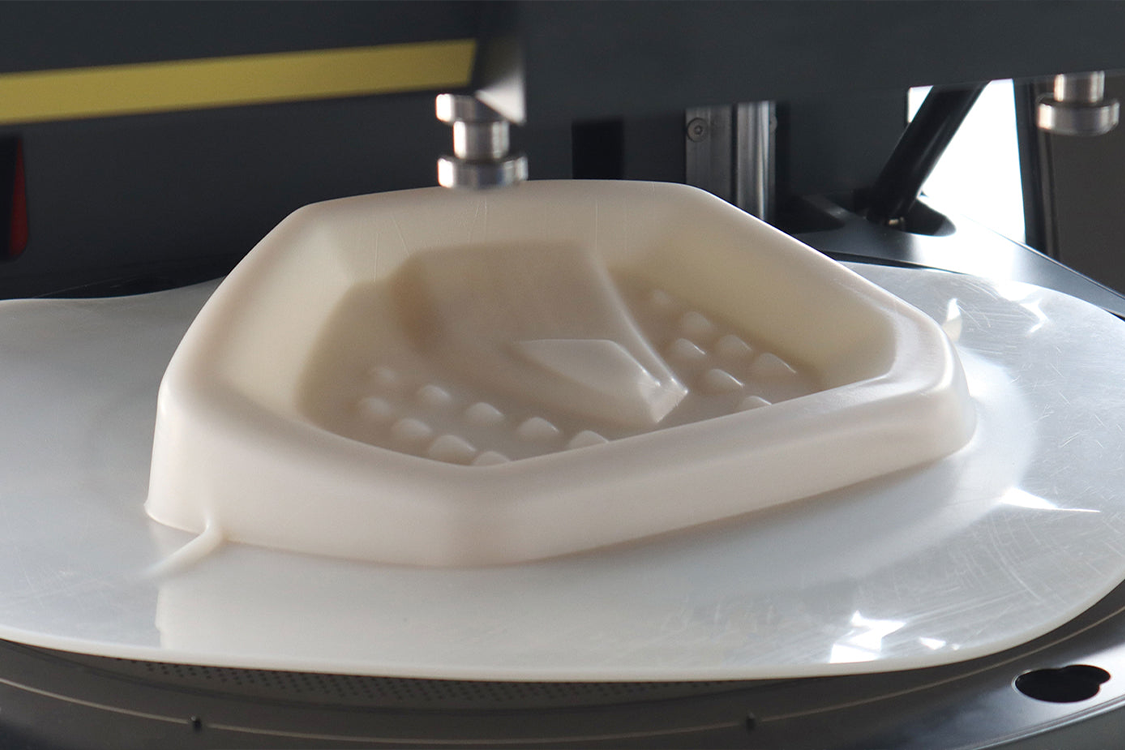

Prefer to read? Check out the comparison guide.Practical Guide: Thermoforming and filament 3D printing (FDM)

Check out this practical guide from Mayku, where Agustín Arroyo explores the benefits of using filament 3D printing (FDM) to create thermoforming templates or tools that can be used on both vacuum forming and pressure forming machines.

Watch this guideGuide: Creating thermoforming templates with FDM 3D printing

In this article, Mayku explores the benefits of using filament 3D printing to create thermoforming templates in more detail. By understanding the potential of this technology and its use in the thermoforming industry, you can make informed decisions about which method of template fabrication is best for you.

Read the guide here.Mayku Multiplier double-sided casing batch production workflow

This document details the entire workflow involved for producing a double sided product casing using a combination of 3D printing, pressure forming and laser cutting.

Read the guide here.