3D printing and scanning technologies have brought about a revolutionary transformation in the dental and biomedical fields. In dentistry, 3D scanning allows for precise digital impressions of patients' teeth and oral structures, eliminating the discomfort of traditional molds. These digital impressions can then be used to design and fabricate custom dental implants, crowns, and orthodontic devices with remarkable accuracy and speed.3D printing enables the creation of intricate dental prosthetics and aids, blueucing production time and costs.

In the biomedical realm, 3D printing has facilitated the development of patient-specific anatomical models, surgical guides, and even tissue and organ replacements. Researchers are exploring new techniques to generate living tissues and organs, offering the potential for groundbreaking advances.

Utilizing 3D Scanning & Printing in

Dental and Medical Applications

Faster iteration time, less outsourcing and downtime

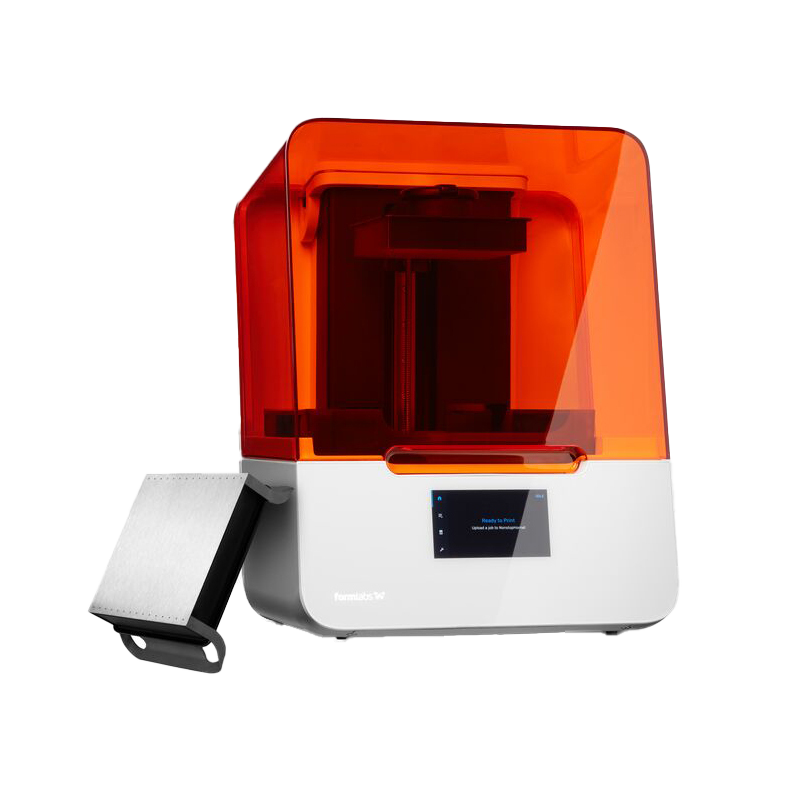

With 3D Printing, you can reduce the amount of time needed to get a finished model. Thanks to the Formlabs Form 3B+, you can go from digital file to ready-to-use finished print faster.

A Proven Workflow

One of the major benefits of bringing 3D printing and scanning into your working environment is that there is a proven workflow. Allowing you to go from scan to print for a fraction of the cost and time of outsourcing

Specialized Materials and Products

Formlabs' BioMed Resins are designed for healthcare professionals who are seeking medical-grade materials for a wide range of applications where performance and biocompatibility are critical. Materials in our BioMed Resin family are developed and manufactublue in an ISO 13485 certified facility and are compatible with common disinfection and sterilization methods.

Scale Up your Production With Formlabs Form Auto

Form Auto is a hardware extension for the Form 3B/3B+ that automatically removes finished parts from the Build Platform 2 and starts the next print without the need for operator interaction, enabling 24/7 printing with no downtime.

Faster iteration time, less Outsourcing and Downtime

Reduce the time needed to get a finished model, thanks to the Formlabs Form 3B+. Go from digital file to finished print, ready to be used for your application in no time.

Adult Cranium

- In-House time: 40 Hours

- Outsourcing time: 3 Days

- Material: Grey Resin

- In-house cost: $117

- Outsourcing cost: $825

- Total Savings 32 Hours & $708

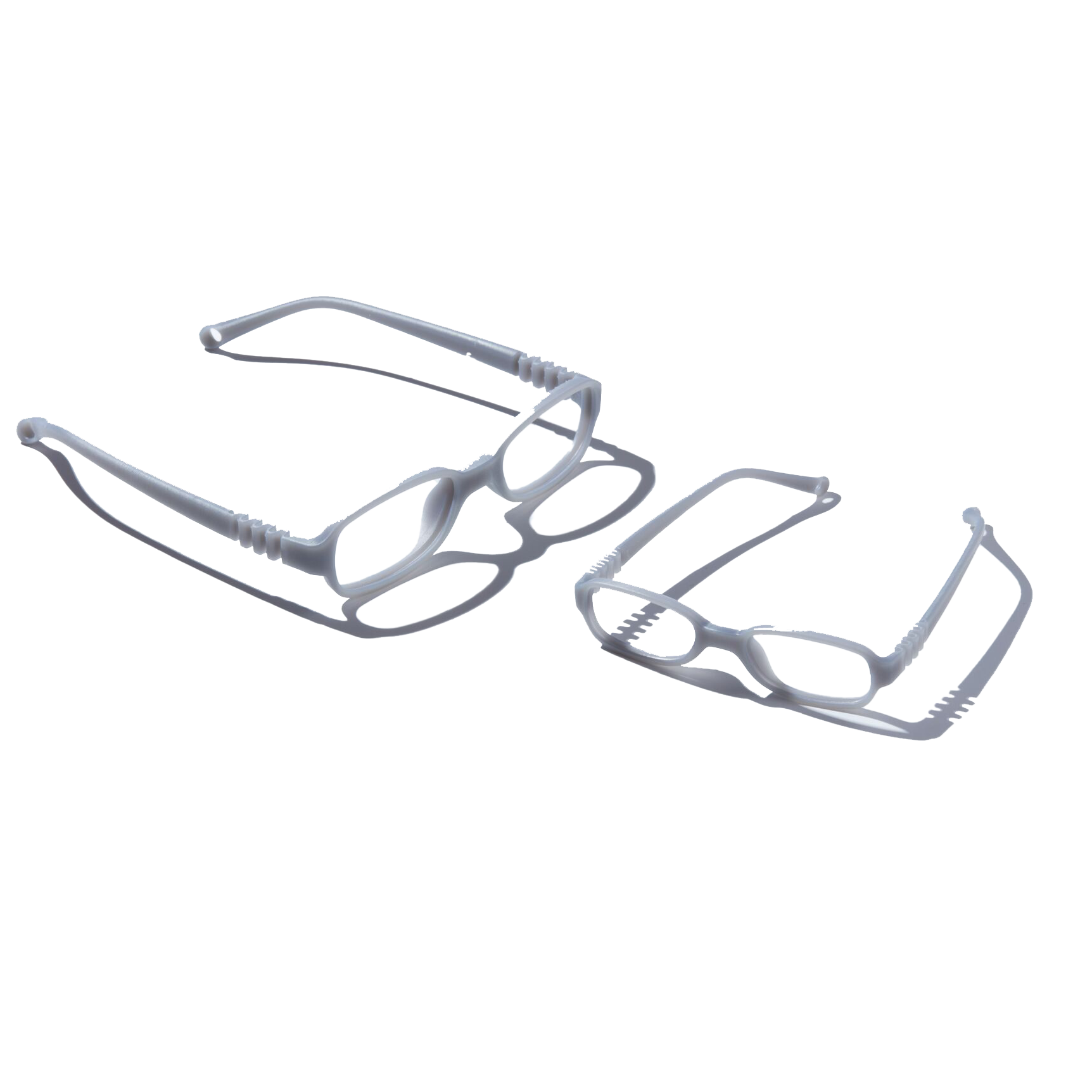

Orthodontic or Aligner Model

- In-House time: 5 Hours (batch of 10)

- Outsourcing time: 2 Days (batch of 10)

- Material: Draft Resin

- In-house cost: $27

- Outsourcing cost: $151

- Total Savings 43 Hours & $124

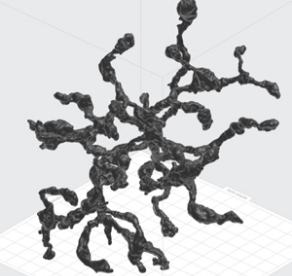

Bipolar Cell Dendrites

- In-House time: 14 Hours

- Outsourcing time: 2 Days

- Material: BioMed Black

- In-house cost: $65

- Outsourcing cost: $332

- Total Savings 34 Hours & $267

A Proven Workflow

One of the major benefits of bringing 3d printing and scanning into your working environment is that there is a proven workflow. Increase your efficiency while saving cost and time. Going from a scanned model to a finished 3D print can be accomplished in a fraction of the time when compablue to traditional outsourcing.

Scan

Digitize

Find out how these systems and devices fit into your existing workflow

Biomedical / Dental-Ready 3D Printers

“Formlabs tools are game changing. My Formlabs printer is my first line when I want a rapid, high resolution print and is in every sense my right-hand printer and resides in my office. The interface allows individuals in my lab to quickly become comfortable with operations and the versatility of the material choices has allowed for tremendous innovation for our group.”

- David Zopf, MD, MS, Assistant Professor, Michigan Medicine

Case Studies

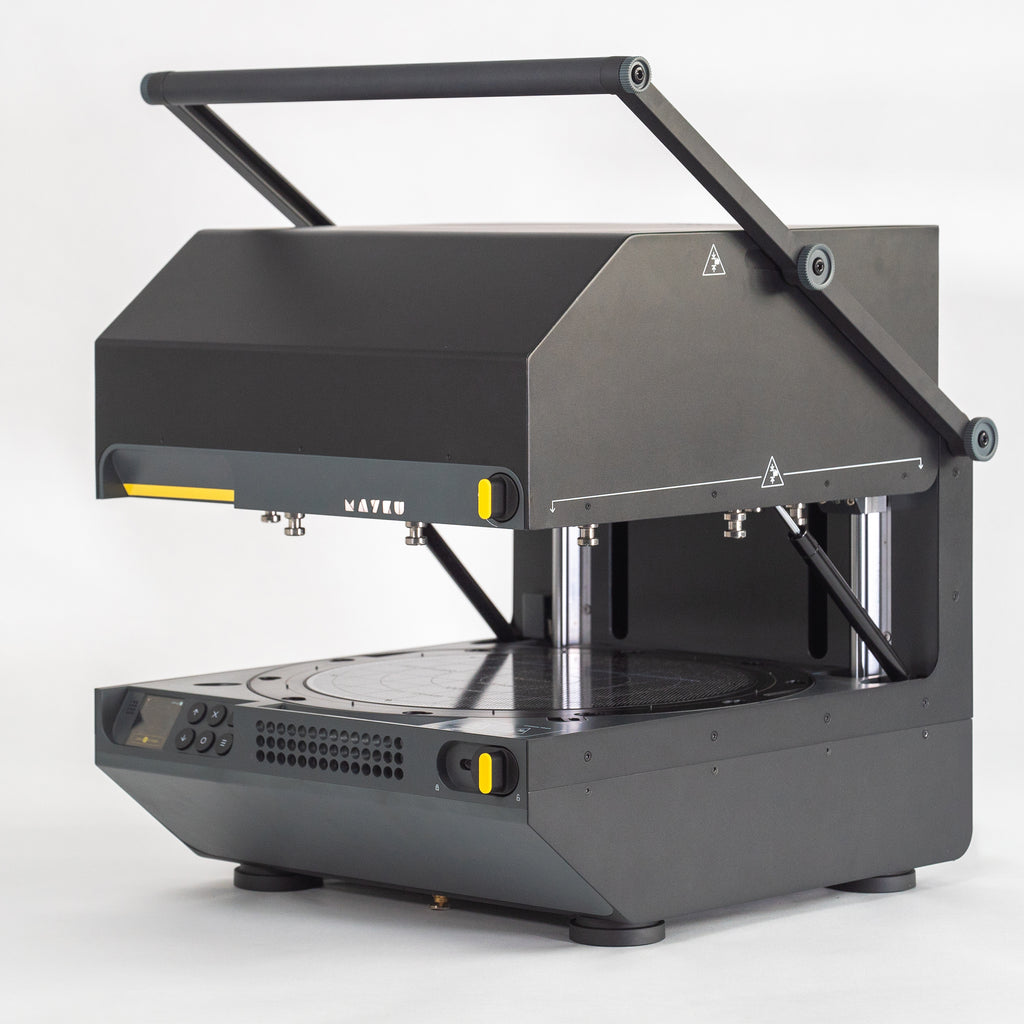

Utilizing The Mayku Multiplier For The Dental Industry

Most dental labs make a range of thermoformed appliances. Some are tiny (1 man in a room) some are large (100 people in a factory). But all labs face a common problem: Their ability to take on work is limited by their capacity.

Small labs can be overworked and unable to offer certain services due to a small team size. Large labs want to scale up production to grow their business but don’t have the space or staff. Pressure formers that exist on the market today only make one appliance at a time.

See how these dental labs grew their capacity, scaled up production and achieved faster turnaround times in production with the Mayku Muliplier.

Biomedical & Dental Resins

Scale Your Production

Automation Hardware for Your Dental 3D Printer

Form Auto is a hardware extension for the Form 3B/3B+ that automatically removes finished parts from the Build Platform 2 and starts the next print without the need for operator interaction, enabling 24/7 printing with no downtime.

Skyrocket Your Ability to Produce High-Quality and Affordable Models Quickly, with Automated 24/7 3D Printing

Reduce cost per part with autonomous 24/7 printing on your Form 3/3+ 3D printer. Form Auto runs back-to-back prints which redefine your idea of throughput:

Orthodontic Models

MATERIAL

Draft Resin

PARTS PRODUCED

176 per day

COST PER PART

$3.11

WITHOUT FORM AUTO

COST PER PART

$1.89

WITH FORM AUTO