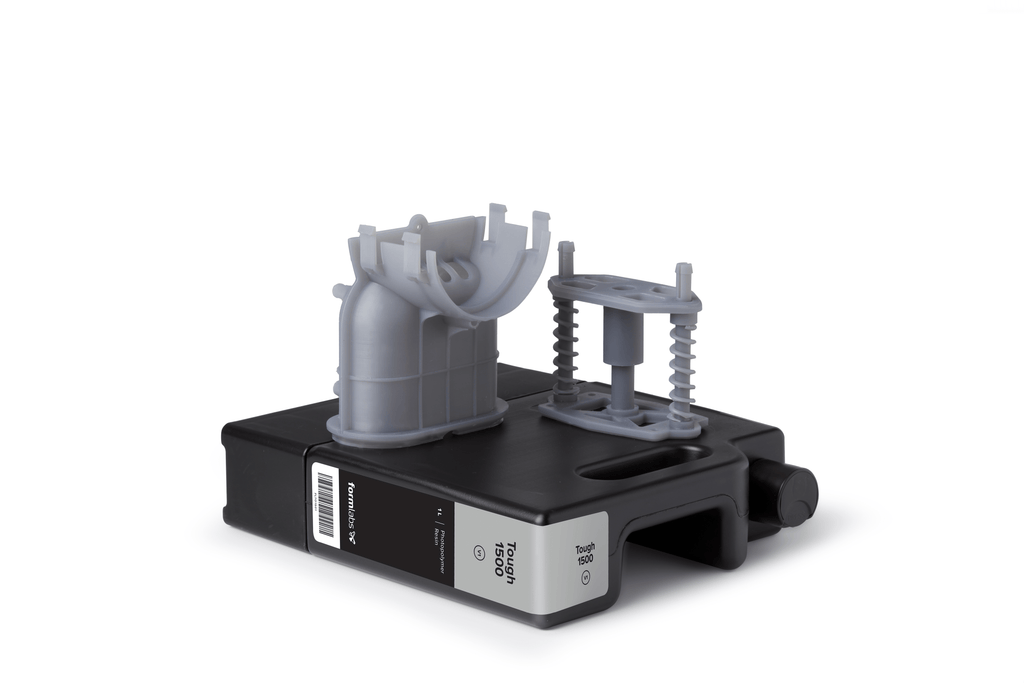

Tough 1500 Resin is the most resilient material in our functional family of Tough and Durable Resins. It produces stiff and pliable parts that bend and spring back quickly under cyclic loading.

We’re excited to share that Tough 1500 Resin has been evaluated for skin contact safety in accordance with ISO 10993-1, and has passed the requirements for the following endpoints:

| Voltage | 24 V |

| Material | Aluminum+titanium alloy+brass+silicone |

| Installation type | Insert directly into the extruder |

| ISO 10993-10 | Not a sensitizer |

Paired with Tough 1500 Resin’s stiff and pliable performance, these test results make Tough 1500 Resin ideal for extended skin contact applications such as wearables, personal protective equipment, and other consumer goods.

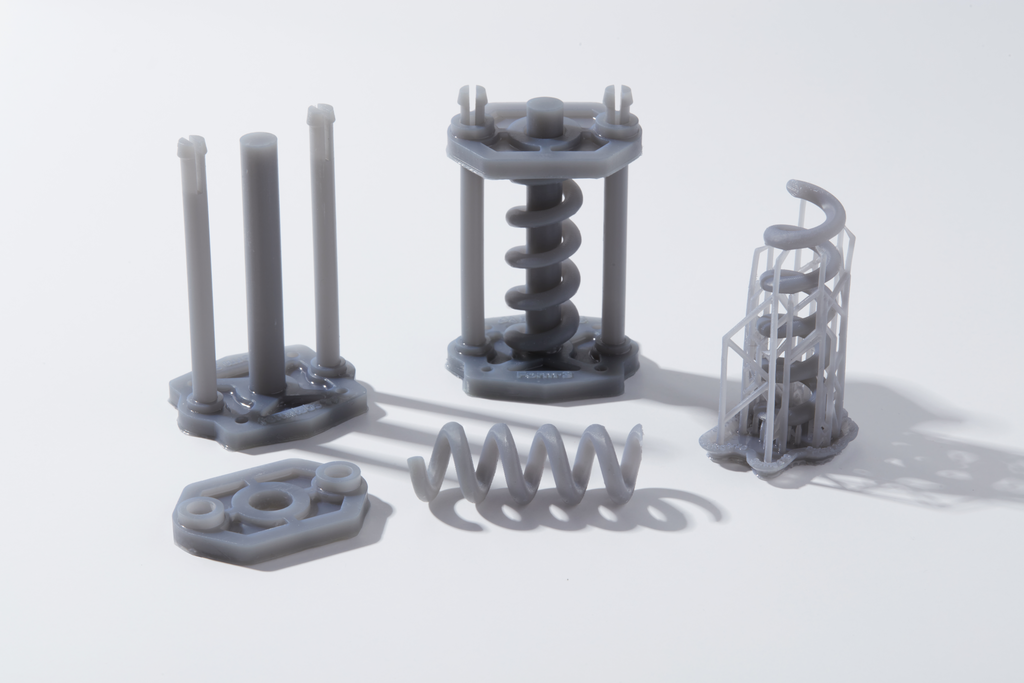

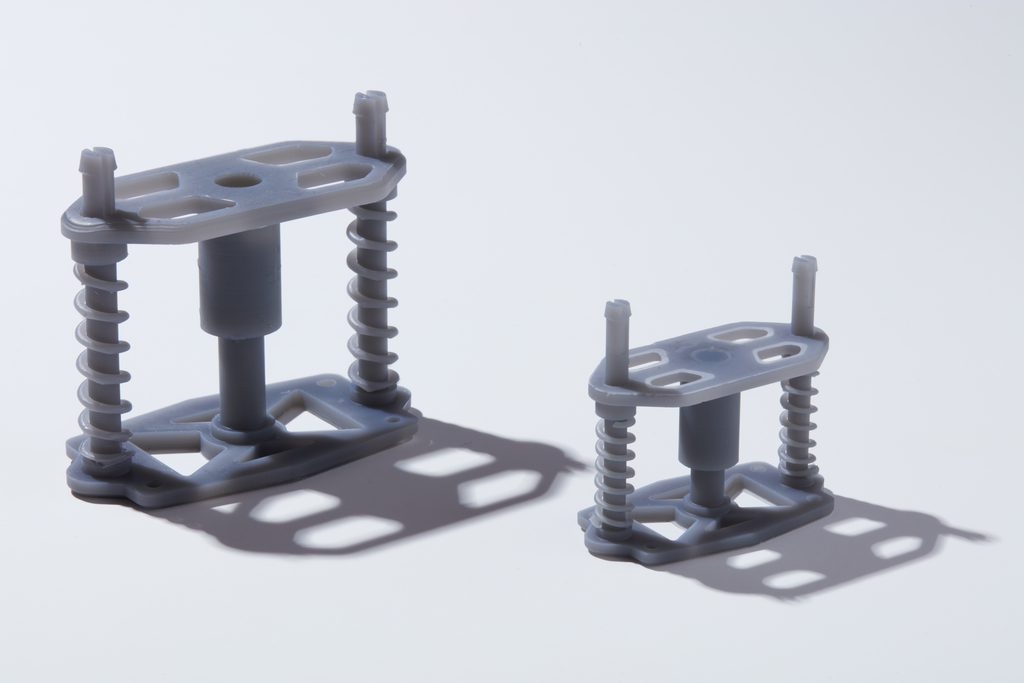

- Fatigue resistant

- Faster spring-back than Durable Resin

- Increased Elastic behaviour over Tough (more bendable than Tough V5)

- Professional light grey colour

- Tensile Modulus: 1500 MPa | 218 KSI (when fully cured)

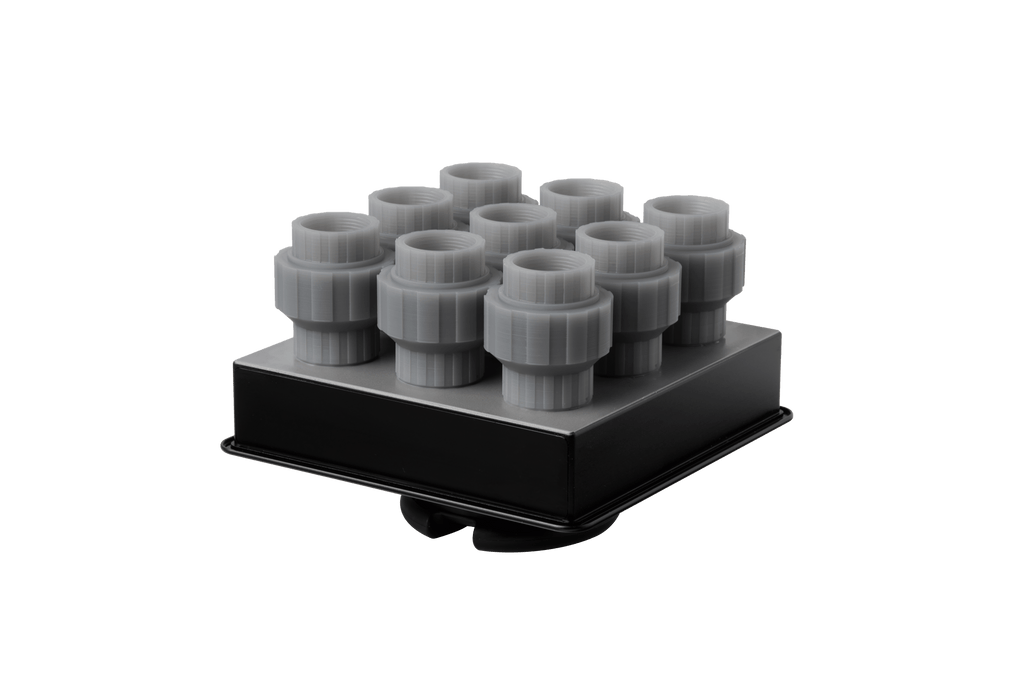

- Springy prototypes and assemblies

- Snap fit and press fit connectors

- Simulating the strength and stiffness of Polypropylene (PP)

Whether you’re optimizing your manufacturing process, rapidly iterating through designs, or assessing form, fit, and function, our Engineering Resins for the Form 2 / Form 3 are formulated to withstand extensive testing and perform under stress.

Supports Print Resolutions: 100 and 50 microns

Curing Period: 60min at 70 degrees

Due to its high elongation and moderate modulus Tough 1500 Resin is ideal for parts that bend, but require high memory retention. When pushed to its stress limit, Tough 1500 parts will strain significantly before permanently deforming and ultimately breaking.- Prototypes that repeatedly bend and quickly return to shape

- Jigs and fixtures requiring repeated deflection

- Simulating the strength and stiffness of Polypropylene (PP)

Durable Resin is the most pliable, impact resistant, and lubricious material in our functional family of Tough and Durable Resins. Durable Resin is perfect for squeezable plastic parts and low-friction assemblies that experience significant wear and tear. Due to its low modulus and high elongation, Durable Resin deforms significantly with relative ease under load compared to Tough (v5) and Tough 1500 Resins. When pushed to its stress limit, Durable parts will strain significantly before permanently deforming and ultimately breaking.

All Engineering resins requires UV post-cure when finishing for it to be fully cured, please consider the Form Cure to properly cure your functional resin prints.

Notes on Formlabs Resins and Proper use:

Formlabs Engineering resins come in a resealable and refillable 1 Litre Cartridge.

Resins should be handled in accordance with Formlabs protocols.

A new resin tank should be used per Resin colour/type for your Form 2 / Form 3 printer.

Never mix the use of resin colours or types with a resin tank.

Purchase additional resin tanks here.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.