This filament is compatible with Raise3D Industrial PPA Support Filament.

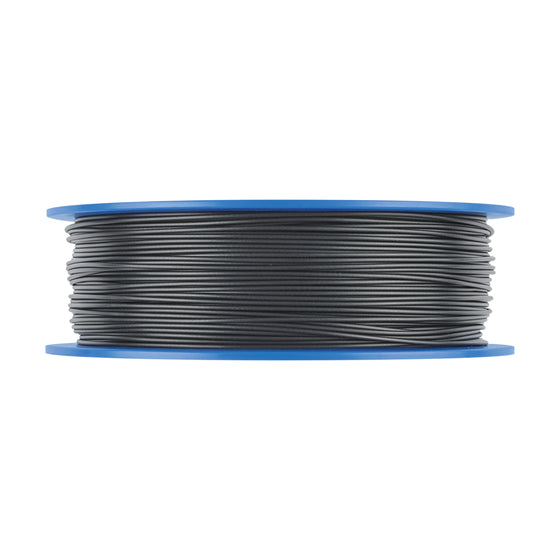

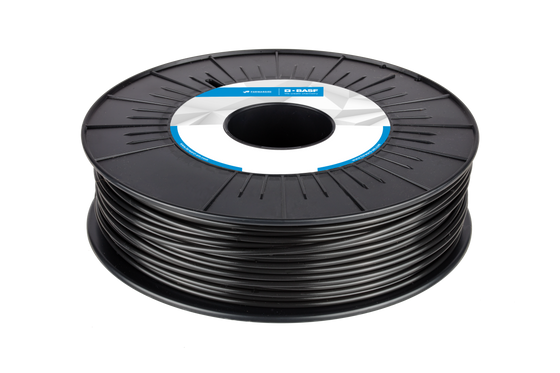

Raise3D Industrial PPA CF Filament is a carbon fiber-reinforced composite filament material based on PPA (polyphthalamide or high-performance/high-temperature Nylon). Thanks to its high-performance Nylon matrix, this composite filament has superior mechanical and thermal properties when compared to other Nylon filaments. With well-controlled dispersion and length distribution of chopped carbon fibers (15 wt.%), PPA CF has a lower density, lower moisture absorption, high strength and rigidity, high wear and creep resistance, and excellent chemical and heat resistance. It is promising for end-use applications in the automotive, aerospace, electrical and electronics (E&E) industries.

- High rigidity and strength

- Better thermal performance

- Lower moisture absorption

- Dimensional stability

- Chemical resistance

- High strength-to-weight ratio

- Automobile

- Aerospace

- Electrical and electronics (E&E) industry

- Industrial end-use parts

- Extruder temp: 290-310C

- Bed temp: 65-80C

- Print speed: 30 - 210mm/s depending on the printer

- Cooling fan: Off

- Abrasion resistant nozzle recommended

- Dry filament for 4-6 hours at 80-100C and let cool to room temperature before printing

- It is recommended to anneal your parts to get the best material properties. We recommend putting the parts in for 6-8 hours and 80C and let cool to room temperature.

- Annealing

- Anneal for 8-12 hours at 80-100C and let the parts cool down to room temperature naturally.

- If you're using same material supports, make sure to remove those before annealing as the support and part can adhere to each other permanently.

- If using PACF support material, leave it on.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.