Users of the X1-Combo and P1S-Combo require AMS 2 Pro Switching Adapter for full functionality (sold separately).

Users of the standalone X1C and P1S (without an existing AMS1) will require the AMS 2 Pro Upgrade Kit (sold separately).

Benefits of Buying Bambu Lab from Shop3D.ca

Certified & Approved Products

- ESA-approved and SGS certified printers for the Canadian market

- Approved vendor for government, education, and diversity-certified supplier

Comprehensive Training & Support

- Free onboarding training for educational institutions

- Account managers providing recommendations and best practices

Warranty & Repair Services

- Bambu Lab warranty with local troubleshooting and parts

- Local repair facility and warranty facilitation

Convenient & Responsive Local Support

- Immediate response via phone or chat

- Local pickup available in Vancouver and Mississauga

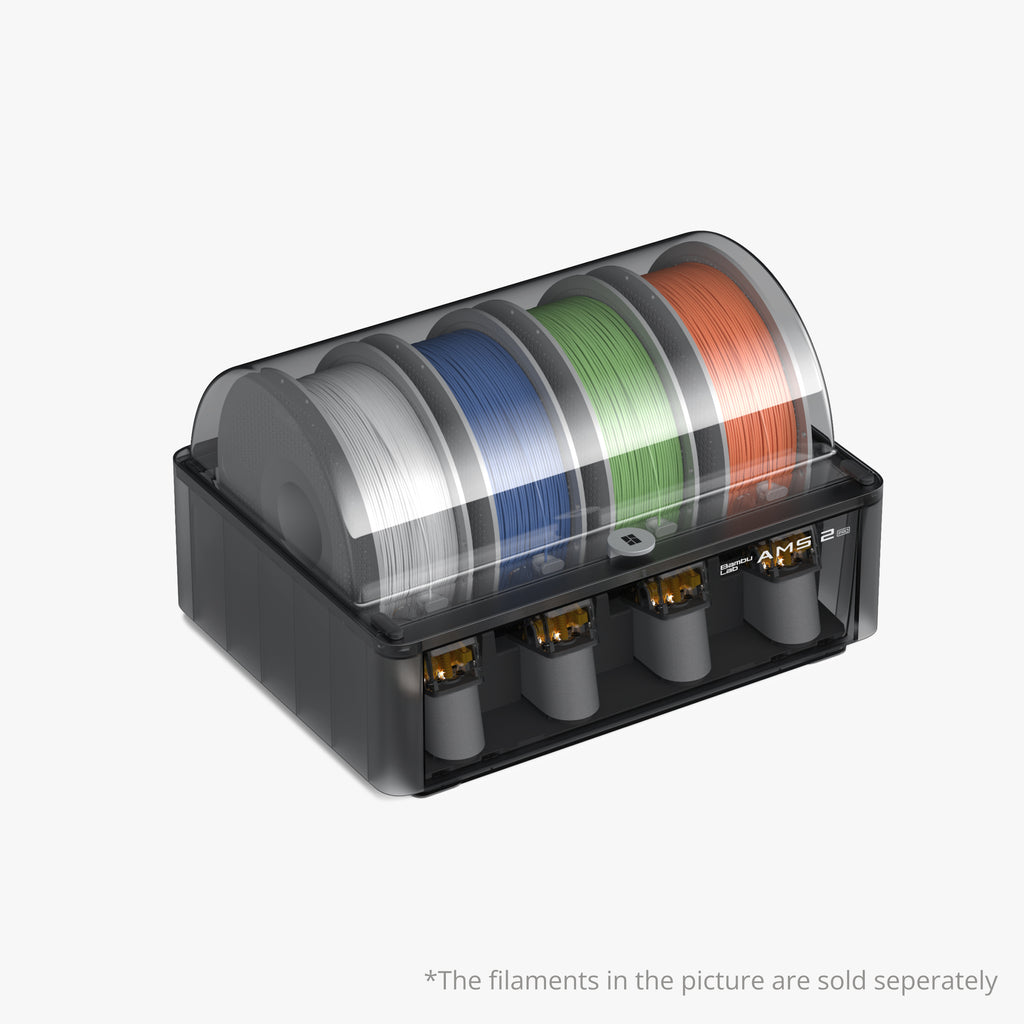

- Active Air Vent 65°C Filament Drying

- Air-tight Filament Storage

- Up to 24-color/Multi-material Printing

- Brushless Servo Feeding Motor

- RFID Filament Sync

- AMS 2 Pro compatibility with A1/A1 mini printers will be added through an OTA update in Q3 2025

Serially connect up to 4 AMS 2 Pro & 8 AMS HT units, total of 24 filaments

Air Vent Fast filament drying & air-tight filament storage

Up to 65°C drying temperature

60% faster feeding speed

Electro-Magnetic Air Vent

Automated venting facilitates dehumidification during drying and ensures airtight sealing for weeks of high-quality printing.Auto-rotate Drying

During the drying process, the filament spools rotate automatically to ensure more even drying.RFID Sync

AMS 2 Pro uses RFID to auto-match drying settings for Bambu official filaments, no manual input needed

Bambu PETG Basic

Speed Up! Faster Multi-material Printing!

The powerful Bambu permanent magnet synchronous servo motor accelerates filament feeding by 60% for enhanced efficiency.

Saves an average of 10 minutes per 100 filament changes.

Faster multi-color printing

Evolved, Polished Design Details

Tool-Free Filament Tubes Access

Removing snapped filament from the first-gen AMS requires extracting all spools and disassembling the shell with two screws, taking 3-5 minutes. In contrast, the AMS 2 Pro offers direct, tool-free access to filament tubes from the top.

Ceramic Inlet

Ceramic filament inlets with Vickers hardness of 1200 significantly enhances durability.

Compatible With All Bambu Lab Printers

The AMS 2 Pro is compatible with all Bambu Labs products.

* Filaments marked with * require higher drying temperature. The AMS 2 Pro cannot dry them completely. If you want better drying performance for these filaments, we recommend purchasing an AMS HT.

What’s in the Box

Bambu AMS 2 Pro

Desiccant

PTFE Tube

Bambu Bus Cable-6Pin

1.There is an independent power port on the AMS 2 Pro in addition to the 6-pin port. Is this necessary?

When the H2D is used with a single AMS 2 Pro, all functions, including automatic feeding and drying, can be utilized without an external power adapter.

When the H2D is used with more than one AMS 2 Pro, if some AMS 2 Pro units are used for multi-color printing while others are used for filament drying, then the AMS 2 Pro units used for drying require an external power adapter. The external power adapter can be purchased from the Bambu Lab official store.2.Can the X1 Series and P1 Series printer us AMS 2 Pro?

X1 Series and P1 Series support AMS 2 Pro, if only the automatic feeding function is used, only the 6-pin cable is required, and no external power adapter is needed. However, if you need to use the drying function, an external is required for the AMS 2 Pro. The AMS 2 Pro is compatible with X1/P1 series printers for multi-material printing. The filament drying feature for these older generation machines will be fulfilled through an OTA update by the end of April. AMS 2 Pro compatibility with A1/A1 mini printers will be added through an OTA update in Q3 2025.

3.Can AMS and AMS 2 Pro be used at the same time for printing?

Yes, you can use both AMS and AMS 2 Pro on one H2D.

4.Can I dry filament while printing?

Currently, drying is not supported for AMS 2 Pro/HT that are actively involved in the printing process, including those that may be used for automatic refill during the current print job. Printing while drying is not yet supported. The only "dry while print" scenario currently supported is: the printer uses some of the connected AMS 2 Pro/HT units or an external spool holder for printing, while the AMS 2 Pro/HT units not involved in the current print job can be used for drying. If the printer is feeding or printing and at the same time powering 1 AMS 2 pro for drying, the drying power will be automatically reduced in order to ensure that the printing power is prioritized. So it is recommended to use the external for best drying results.

5.Can I get the power from the printer while drying?

The H2D printer supports powering one AMS 2 Pro for drying directly from the printer. If you need to dry filament in multiple AMS 2 Pro units simultaneously, the additional AMS 2 Pro units require power supply via a (purchased separately).

6.Does it support standalone drying without connecting to the printer?

When using the AMS 2 Pro drying function, the AMS 2 Pro must be connected to the printer via a 6-pin bus cable to ensure that the printer is powered on and set to filament drying mode. The AMS 2 Pro cannot perform standalone drying without a connection to the printer.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.