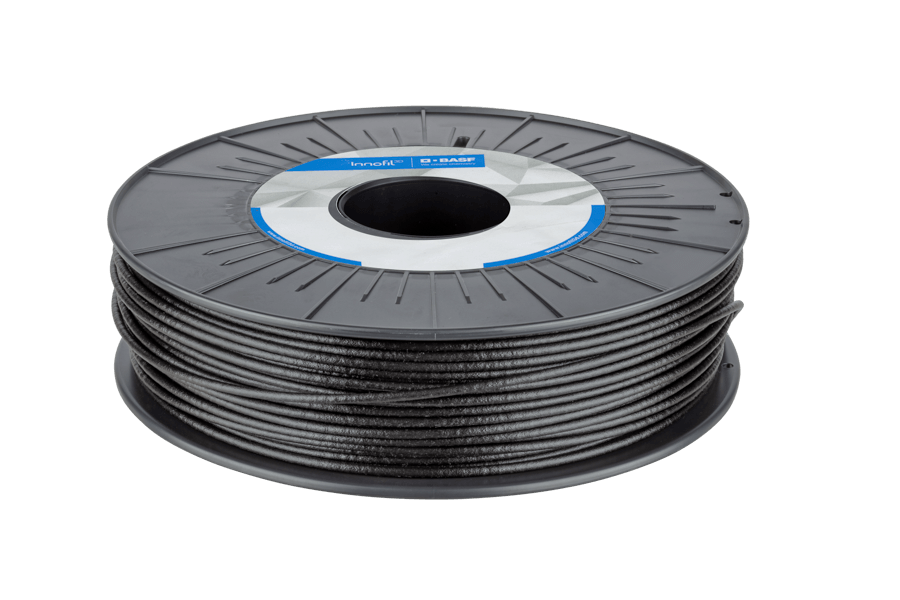

Forward AM Material is proudly produced in Europe

Ultrafuse PP GF30 is polypropylene, reinforced with 30% glass fiber content. The fibers in this compound are specially designed for 3D-printing filaments and are compatible with a wide range of standard FFF 3D-printers. The extreme stiffness makes this material highly suitable for demanding applications. Other key properties of PP GF30 are high heat resistance and improved UV-resistance. All these excellent properties make this filament highly suitable in an industrial environment.

- Extremely high stiffness

- High heat resistance

- UV resistant

- Chemical resistant

- Low density: 1066 kg/m3

- Nozzle Temperature: 240 - 260°C

- Bed Temperature: 20 - 40°C on PP strapping tape | 70 - 90°C with PPGF adhesive

- Bed Material: Glass + PP tape | Glass + PPGF adhesive | Buildtak + PPGF adhesive

- Nozzle Diameter: ≥ 0.6 mm

- Print Speed: 30 - 80 mm/s

Ultrafuse PP GF30 filament should be stored at 15 -25°C in its original sealed package in a clean and dry environment. Drying should be done with these parameters:

- 60 °C in a hot air dryer or vacuum oven for 4 to 16 hours

To print the best possible way with Forward AM filaments

Forward AM provides you with a large range of printing profiles for their materials based on different well-known printer manufacturers like Ultimaker, Raise3D and BCN3D

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.