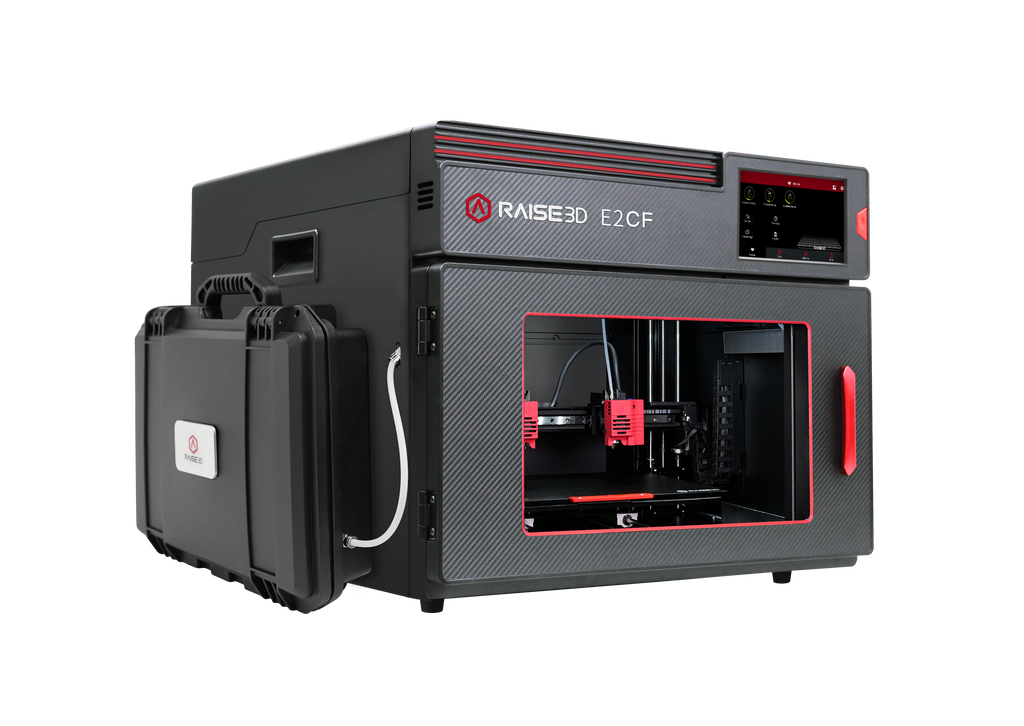

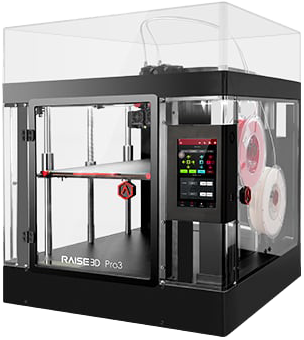

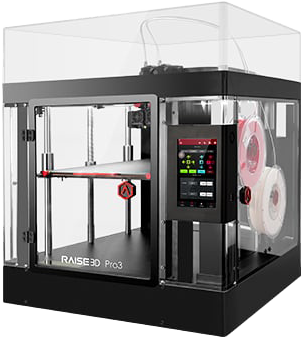

E2CF is a desktop 3D printer developed by Raise3D for carbon fiber-reinforced filaments and other composite materials. Carbon fiber filament has low density, high strength, and it is resistant to corrosion, static electricity and high temperature. It has a wide potential for application in industries that need considerable strength-to-weight ratio in their solutions, such as the aviation industry and the automotive field. The E2CF prints with accuracy, is user friendly, stable when operating and durable. It is a one-stop desktop-level manufacturing tool suitable for various scenarios.

- Build Volume (Single Extruder): 330 × 240 × 240 mm (W x D x H)

- Build Volume (Dual Extruder): 295 × 240 × 240 mm (W x D x H)

- Machine Size: 607 × 596 × 465 mm (W x D x H)

- Filament Diameter: 1.75mm

- Print Head Travel Speed: 30–150 mm/s

- Max Build Plate Temperature: 110ºC

- Supported Materials: Raise3D Industrial PA12 CF, PA12 CF Support, PPA CF, PPA GF, PPA Support (PET CF and PPS CF Coming soon)

- Layer Height: 0.1-0.25mm

- Nozzle Diameter: 0.4 mm (Default), 0.6/ 0.8 mm (Available)

- Max Nozzle Temperature: 300ºC

- Connectivity: Wi-Fi, LAN, USB port, Live camera

- Operating Ambient Temperature: 15-30ºC, 10-90% RH non-condensing

- Storage Temperature: -25 to +55℃, 10-90% RH non-condensing

- Filter: HEPA filter with activated charcoal

- Net Weight: 32.4 kg

- Power Supply Input: 100-240 V AC, 50/ 60 Hz 230 V @ 2 A

- Power Supply Output: 24 V DC, 350 W

- Slicing Software: ideaMaker

- Supported File Types: STL/ OBJ/ 3MF/ OLTP

- Supported OS: WINDOWS/ macOS/ Linux

- Network: Wi-Fi, Ethernet

- Screen Resolution: 1024 × 600

- Motion Controller: Atmel ARM Cortex-M4 120 MHz FPU

- Logic Controller: NXP ARM Cortex-A9 Quad 1 GHz

- Memory: 1GB

- Onboard Flash: 16GB

- OS: Embedded Linux

- Ports: USB 2.0 x2, Ethernet x1

- Power Cable (x5)

- Hex Wrenches

- Filament (x2)

- Tweezers

- Heat Resistant Gloves

- Spatula

- Filament Guide Tubes (x2)

- USB Storage

- Quick Connectors

- Fuse

- Glue

- 0.3mm Feeler Gauge

The Raise3D E2CF printer now comes with more capabilities in carbon fiber filament printing, with even greater flexibility in general filament printing!

With the E2CF printer, you can now print with all the standard non-abrasive filaments including PLA, ABS, PETG, ASA, and more. In addition to this, users can adjust settings and parameters, allowing them to copy existing templates, import E2CF templates, or even create new ones and share them with libraries.

Check here for details on how to adjust your E2CF printer settings to start enjoying these improved features.

Highly Durable Nozzles

The E2CF sports new silicon carbide nozzles, which have excellent wear resistance and thermal conductivity. This will effectively lessen the abrasion that carbon fiber composite filaments subject the nozzle to when printing, making the nozzle much more durable.

Currently Raise3D is in the process of manufacturing newer, more sustainable materials suitable for printing Carbon Fiber filaments. Keep an eye out for them in the near future!

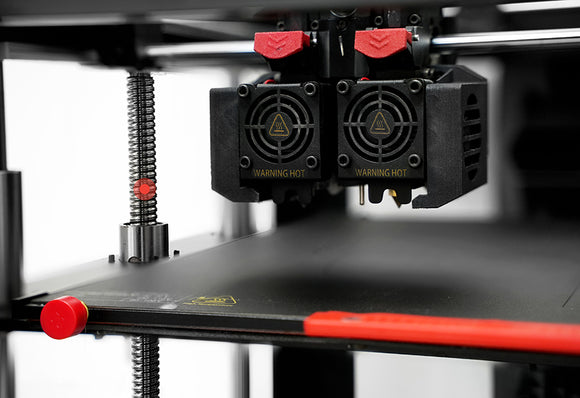

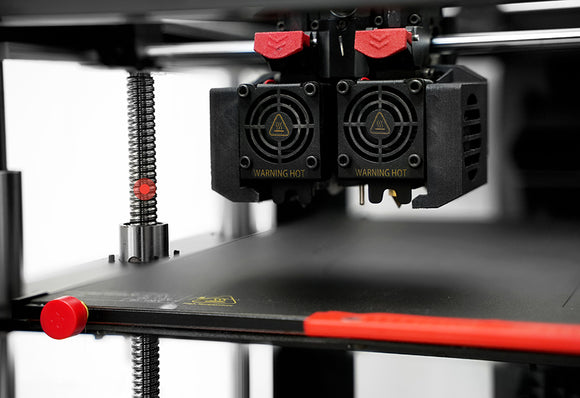

Dual Gear Based Extrusion System

With a custom gear tooth profile, the E2CF allows filament to be firmly held in place to ensure that it does not slip when extruding. The force of the system is optimized to ensure maximum stability during your most challenging prints.

The gears within the extruder are made of a high-hardness steel and have been heat-treated for better wear resistance, allowing you to achieve the best print every time!

Intuitive Print Recovery

Either a power outage or a filament outage (when the filament runs out) can cause a print job to be lost if they occur in the middle of the 3D printing process. However, the E2CF has a filament run-out sensor on its extruders which will send an alert when the filament is about to run out, and will simultaneously save your print job.

The E2CF also has a power loss function to save the printing status in the event of a power outage and can continue printing from the same point when power is restored.

Built-In Filament Storage

The built-in suspension trays are used to place the filament and allow material to be pulled more smoothly. When closed, they can effectively prevent dust and moisture from affecting the material, for a period of up to 30 days*.

*From Raise3D test data

A Wide Range of Slicing Profiles

The E2CF has slicing profiles that have been repeatedly tested and verified by our engineers in ideaMaker. There is no need to adjust the parameters before printing. Enjoy easy and high-quality printing.

Like other Raise3D products, the E2CF can carry out mass production and intelligent management using ideaMaker as the core software solution.

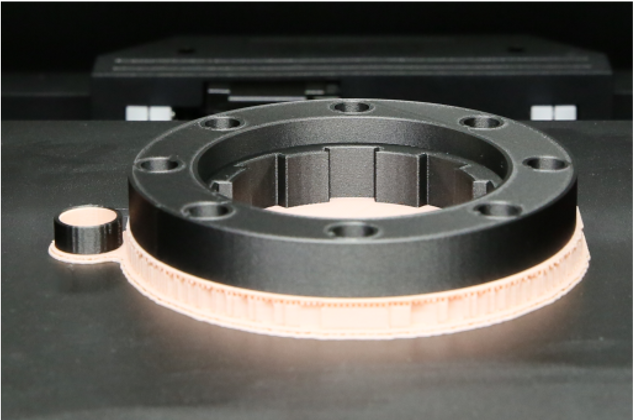

Professional 3D printers, like the E2CF, are quality, user-friendly printers, designed with features to ensure the best possible printing results. For example, the E2CF has a flexible build plate, which allows 3D printed parts to be easily removed, while minimizing potential damage to the part during removal.

Superior Bed Leveling

Bed leveling is the process of confirming that the printing platform is as level as possible. The E2CF has this leveling procedure as an automated function. Auto bed leveling will maintain the distance between the print nozzles and the bed, to create a uniform build area. This improves bed adhesion and allows the extruder to adjust to even the most minor of surface contour changes for better final print quality.

Cloud Based Print Tracking

The E2CF uses a camera to monitor the entire 3D printing process of every print job. This camera operates by connecting to RaiseCloud, allowing users to keep track of every print job remotely and while on the move. This ability to check the 3D printing process gives end users peace of mind.

Accurate & Durable

High-quality 3D printing comes from high-quality 3D printers. The E2CF desktop 3D printer uses a full metal frame to create a specific motion system that allows the machine to smoothly glide as it prints. This motion system works with precise positioning to ensure 3D print jobs are as accurate as possible.

All Raise3D Printers from Shop3D are certified in Canada by eSafe Ontario or QAI Laboratories and have a certification label affixed to the back of each unit. This label is accepted by all electrical regulatory authorities in Canada.

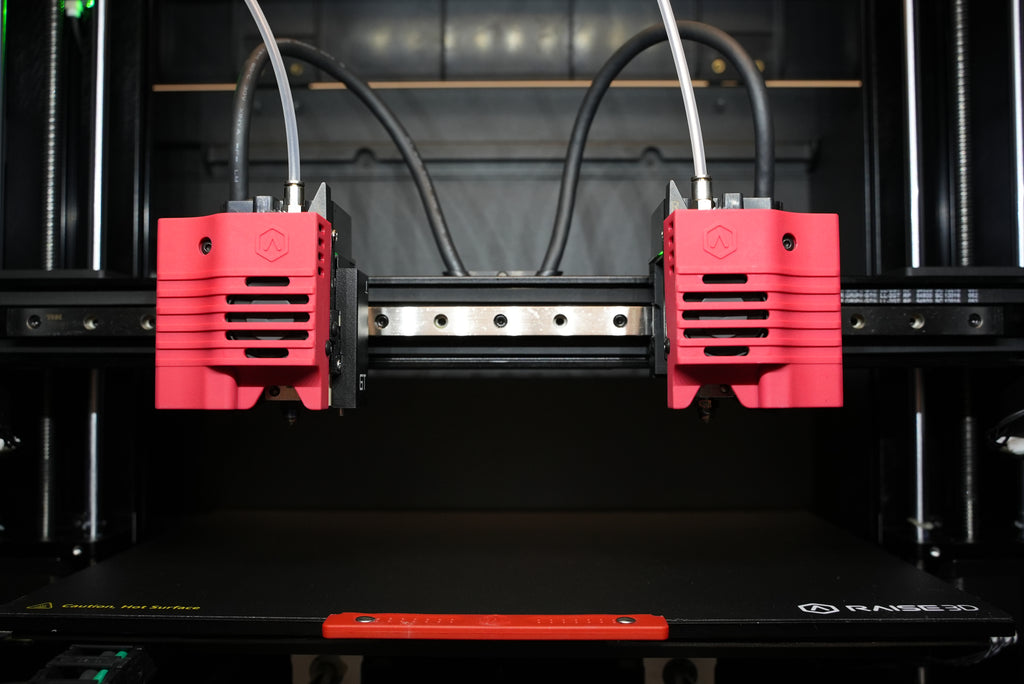

What is IDEX and why is it important?

IDEX stands for independent dual extruders meaning the extruders can operate independently of one another along the same axis during printing to perform more advanced functions.

With IDEX, one extruder can remain motionless and off to the side while the second extruder prints the model, minimizing the risk of the nozzle on the motionless extruder interfering with the print job during dual or single extrusion printing.

What is the function of Mirror Mode & Duplication Mode?

Mirror Mode prints a model and an inverse of that same model at the same time. It is convenient because it saves the effort of creating an additional design file for the inverse model, and it saves the extra time usually spent printing the inverse model separately.

Duplication Mode is synchronized printing, meaning it uses both extruders to print a model and an exact copy of that model at the same time. It can double production capability within the same timeframe.

Which Filaments are compatible with the Raise3D E2CF?

The E2CF pairs perfectly with Raise3D’s Industrial PA12 CF Filament and its support material. In the future, more carbon fiber reinforced filaments will be available for the E2CF, such as Raise3D’s PPA CF, PET CF, PPS CF (with a printing temperature of between 280-300ºC). Also, third-party filaments certified by the Raise3D Open Filament Program, such as BASF and LEHVOSS, will be available to the E2CF later.

The Raise3D Industrial PA12 CF Filament is reinforced with short carbon fibers, and exhibits excellent rigidity and strength, heat resistance, low warpage, and low water absorption. Meanwhile, this material has an outstanding strength-to-weight ratio, and will obtain enhanced mechanical property and dimensional stability after annealing, which makes it suitable to replace metal in the manufacturing of certain lightweight components.

Raise3D Industrial PA12 CF Support Filament is a break-away support material specially developed for carbon fiber reinforced composite filaments. During the 3D printing process, it creates a stable support structure, providing proper adhesion to printed surfaces and counteracting any tendency to warp. As such, it significantly improves the surface quality of the overhangs and hollows of the printed items. After a print is finished, the support structure can be easily removed or broken away from the printed parts. This support material exhibits a broad compatibility with many high-performance carbon fiber reinforced composite filaments, and is more cost-effective when compared with water-soluble support material.

*E2CF only supports authorized filaments and printing profiles. For the full list, please check the tech data sheet or contact Raise3D.

![]() Why Choose Raise3D

Why Choose Raise3D

Another safety feature of the E2CF is that it can automatically detect when a door is opened and will immediately pause the print.

Raise3D Academy

Access Raise3D Academy for step-by-step guides and “how-to” articles, covering topics ranging from setting up and giving maintenance to the 3D printer to performing 3D printing.

Raise3D Support

Raise3D’s Support Center is primed and ready to answer any questions you may have regarding your 3D printer.

ideaMaker

ideaMaker is a free 3D slicing software from Raise3D, compatible with Raise3D printers and third-party printers.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.