eSun Has discontinued the use of plastic spools, newer batches of eSun Filament will have cardboard spools instead of plastic.

Clean & unclog your print core.

After a long time of using your Ultimaker 2 you might notice some signs of “under extrusion”. This means that your Ultimaker 2 can’t extrude enough plastic and is usually shown by very thin or missing layers in a print. In most cases, it is caused by some dirt or carbonized material in the nozzle or another hot end part through which a (partial) blockage is created. When under extrusion appears it is recommended to use the Atomic Method in order to clean the nozzle and other hot end parts. Also, it is good practice to use cleaning filament before switching from one material to another for printing ie. from ABS to PLA, etc.

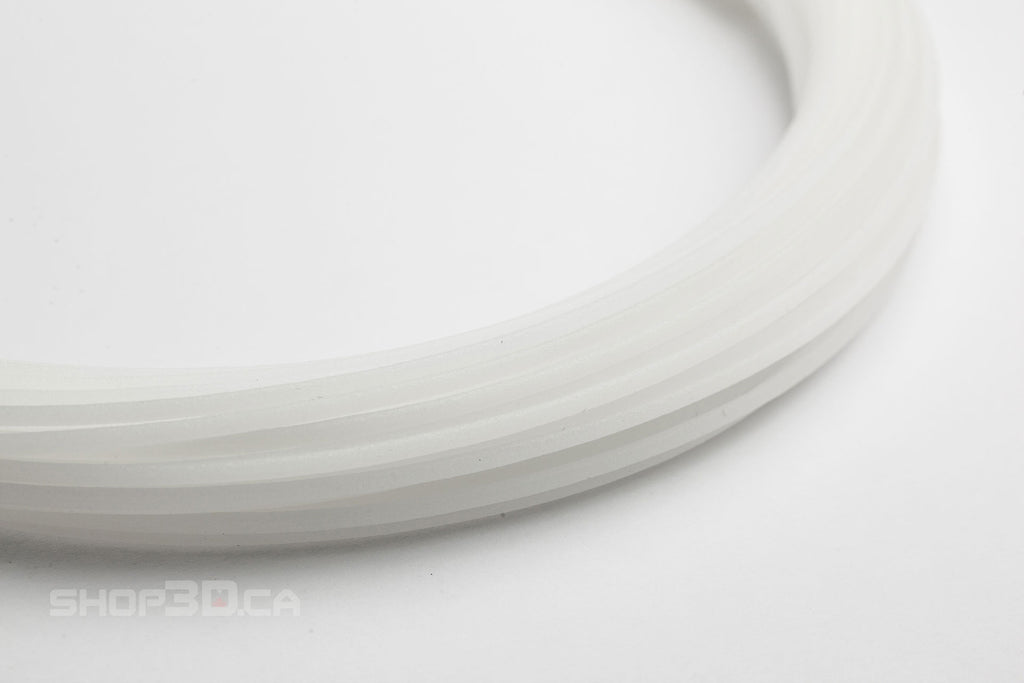

While the Atomic method can be done with regular filament we have found that pushing the cleaning filament through for a few seconds before doing the Atomic Method does an extra good job of cleaning out the nozzle. The cleaning filament stays viscous at a higher temperature and smooths out when it cools (which acts differently than conducting the cleaning with regular filament) resulting in an easier and better cleaning pull. We have found that 1 pull is enough to clean most nozzles vs 3-4 with regular filament.

It comes in a small 0.1kg spool which doesn't seem like a lot but most of the time you'll just be using the tip to do the cleaning and then cutting off the dirty parts so each cleaning cycle is only a few grams resulting in many many cleaning cycles.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.