Formlabs Form 3 vs. Form 2 - Tech Breakdown

April 02, 2019

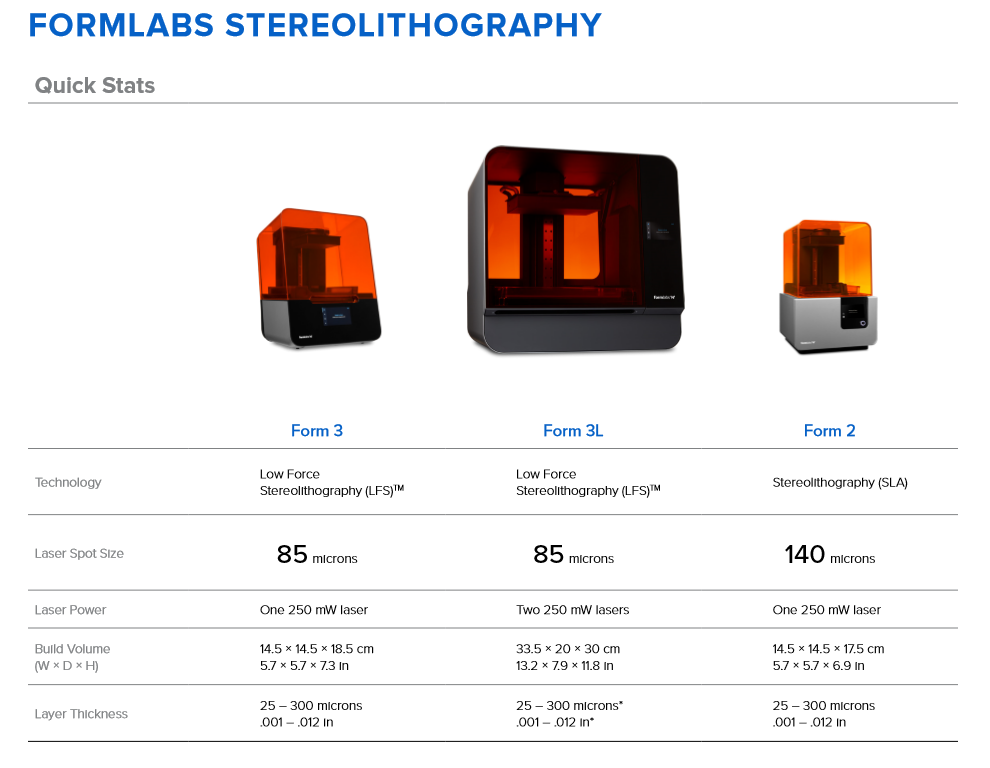

The Form 3 and Form 3L LFS 3D printers from Formlabs provide a new approach to SLA that delivers consistently incredible part accuracy and surface quality. See how these new features compare with the existing Form 2.

Form 3, Form 3L and Form 2 Specs

Main Features

User replaceable Optical module

Smart, redesigned optical module allows users to easily replace the core laser module. Reduce downtime, stock backup parts, and allow for future optical module upgrades.

Perpendicular laser motion control

The Form 3’s state of the art laser system now stays perfectly perpendicular with the build surface ensuring edge to edge consistency at any build volume. Increased spot and overall surface quality.

Backward Compatibility

Form 2 users can enjoy an easy transition. The Form 3 uses the same Pre-form workflow and interface. Resin Cartridges, Buildplates, Form Wash and Form Cure are fully compatible with the Form 3.

Low Force Peel

Completely redesigned Peel system reduces peel forces. This allows for more reliable printing of difficult parts, large layers and dramatically improves part quality.

Even Better Print Quality

The Form 3 revolves around part quality, with many laser, peel and support improvements, part quality is more consistent and is even more crisp, beautiful and detailed than ever before.

Smaller supports required

Cleanup even easier now with the new low force peel technology. Because of lower forces on the part throughout the print, supports and touch points can be a lot smaller resulting in a much easier post-cleanup process. Less blemishes, less labor, less material used.

Longer tray life

Form 3 Resin tanks now last 20 times longer than standard Form 2 tanks so you can keep churning out parts without worry.

Initial batches of Form 3’s directly from Formlabs will not have the cULus certification as on the Form 2. Shop3D intends to have them certified to comply with ESA requirements in Canada prior to delivery to customer at no additional charge. Part of our promise to deliver the best services to Canadians.

General SLA Features

Unparalleled Surface quality

SLA printing produces the highest quality prints. With parts that come off the machine looking like they’re injection molded. Layer lines are minimal, details incredible. From detailed jewelry casting masters to dental crowns, the Form 3 is unmatched in part quality, detail and cleanliness.

Reliable

With a super high success rate (90%+) You don’t need to worry about failed prints the next day. Run the machine 24/7 on production or prototyping tasks. All can be done on one machine without reconfiguring or calibrating.

Ease of use

Resins are thoroughly tested by Formlabs and all settings are pre-set and optimized so you don’t need to tweak Any settings. Simply choose your resin, resolution and print. Everything else is taken care of behind the scenes.

Future proof

With drop in modules, and constantly evolving library of resins, the Form 3 is the platform in which the future 3D printing will happen. From niche and industry specific resin like Castable and High temp, to experimental resins like Ceramic and Colors, you can be sure there will be steady stream of new developments on the horizon.

Resin compatibility

Make use of Formlabs’ already impressive resin library from day 1. Over 15 general and niche application resins. From dental, high temperature to castable resins, all with one system.

Also in News

2025 HOLIDAY HOURS

December 05, 2025

As we gear up for the holidays, our schedule will look a little different. Please take note of our adjusted hours!

Holiday Shipping Notice 2025

December 05, 2025

With the holidays fast approaching, shipping volumes for Canada Post and all other couriers are expected to be higher than usual.

If you’ve been eyeing a 3D printer or accessory to gift that special person, or you’re looking to pamper yourself with a 3D printing gift this season, delay no further! We encourage you to plan ahead to give extra time to allow for the arrival of your order.

If you’d like your order to arrive before Christmas, make sure to order by December 12th.

Shop3D.ca at ADM Toronto (Advanced Design & Manufacturing Expo)

September 23, 2025

Shop3D.ca, Canada’s leading provider of 3D printing solutions, is proud to announce its participation in the Advanced Design & Manufacturing Expo (ADM), taking place October 21 – October 23, 2025, at the Toronto Congress Centre.