Shipping Notes:

If stock is not listed in a Shop3D location, it will be shipped directly from a Canadian distributor warehouse with a longer lead time. Any concerns, please contact our sales team.

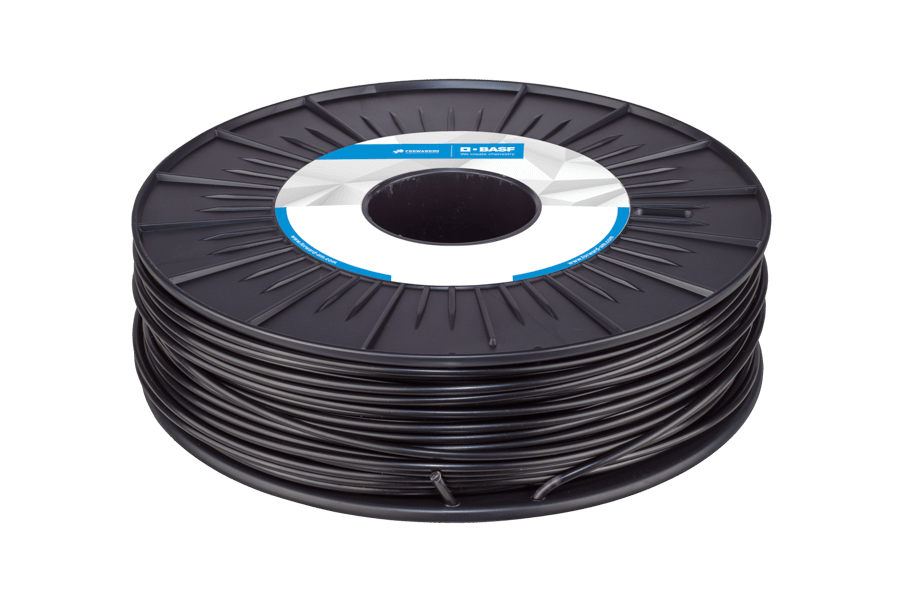

UltiMaker ABS (acrylonitrile butadiene styrene) is formulated to minimize warping and ensure consistent interlayer adhesion. ABS material is a great choice for creating functional prototypes and complex end-use parts.

- Print bed: 80 C

- Nozzle temp: 250 C

- Fan: 20% (Your print will fail if set too high)

- Bed Material: glue stick + glass (gluestick a must)

- Adhesion Setting: Brim

- Door: recommended (advanced printing kit)

- Excellent interlayer adhesion

- Good bed adhesion

- Enhanced strength for functional prototypes and manufacturing end-use parts

- Enhanced mechanical properties over regular ABS

- Not suitable for applications where the printed part is exposed to temperatures up to 85ºC

Every material has different properties. Our comparison tool helps you select the best one for your application.

- PLA/ABS: You’re now comparing an aesthetic material to a technical one. PLA is easy to use and has good surface quality, whilst ABS is better for functional parts that require impact strength and dimensional stability. There’s a transparent PLA option available.

- CPE/ABS: You’re now comparing two technical materials. CPE is odorless, strong and has better chemical resistance than ABS. ABS is as strong as CPE, but can withstand slightly higher temperatures. There’s a transparent CPE option available.

ABS plastic spools come in 0.75kg. 2.85mm diameter and approximately 90m long.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.