Designed for maximum output and minimum waste, Fuse 1+ 30W is our compact SLS 3D printer that packs an industrial punch. Unlock unprecedented print speeds and a full range of materials to deliver truly rapid prototyping and production in-house.

Building on effective powder containment and an easy setup, Fuse 1+ 30W is equipped with a powerful, 30W laser enabling same-day delivery of prototypes and end-use parts. Active powder handling unlocks the use of exclusive, new materials such as carbon fiber-reinforced nylon, and a nitrogen purge print option allows for unprecedented performance and consistency across all SLS parts.

- Fuse 1+ 30W Printer 120V

- Build Chamber 230V

- Fuse Depowdering Kit Workspace and Tools

- Fuse Depowdering Kit Sifter (120V) with 150 Sieve

- Fuse 1 Powder Cartridge

- Build Chamber 230V

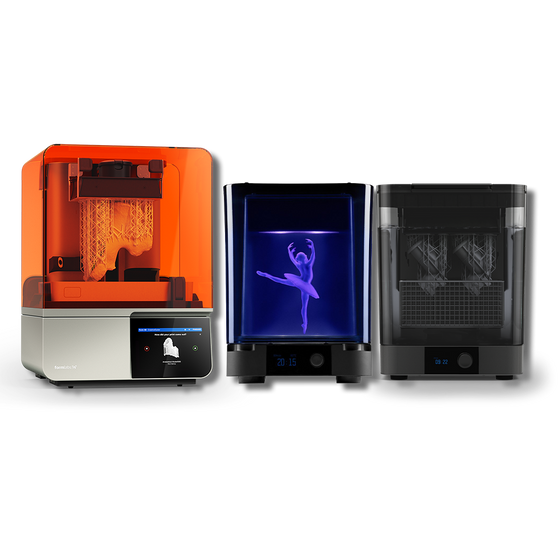

- Fuse Sift

- Powder Cartridge

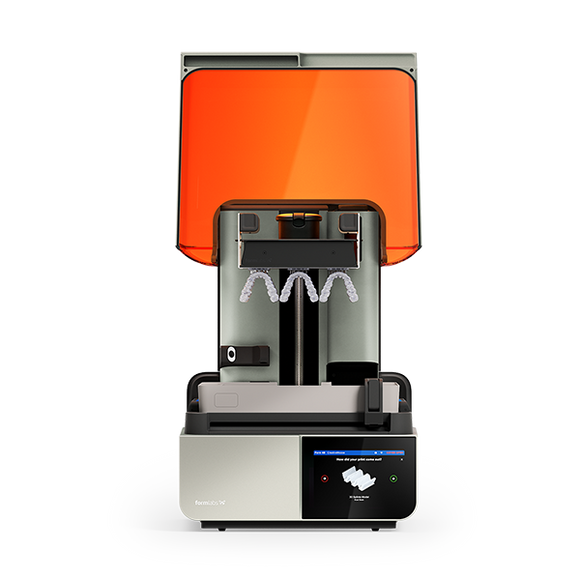

- Prints up to 2x faster than Fuse 1 thanks to its powerful 30-Watt laser and enhanced galvanometer system

- Exclusive new materials enabled by the upgraded powder handling system

- Enhanced mechanical properties on existing and new materials thanks to the option to print in an inert gas environment with the nitrogen input.

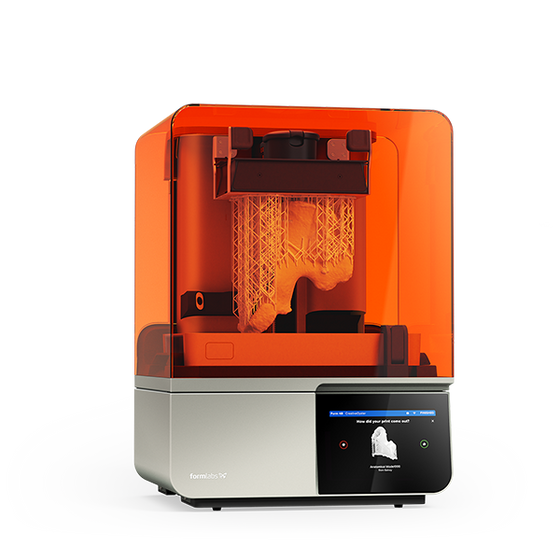

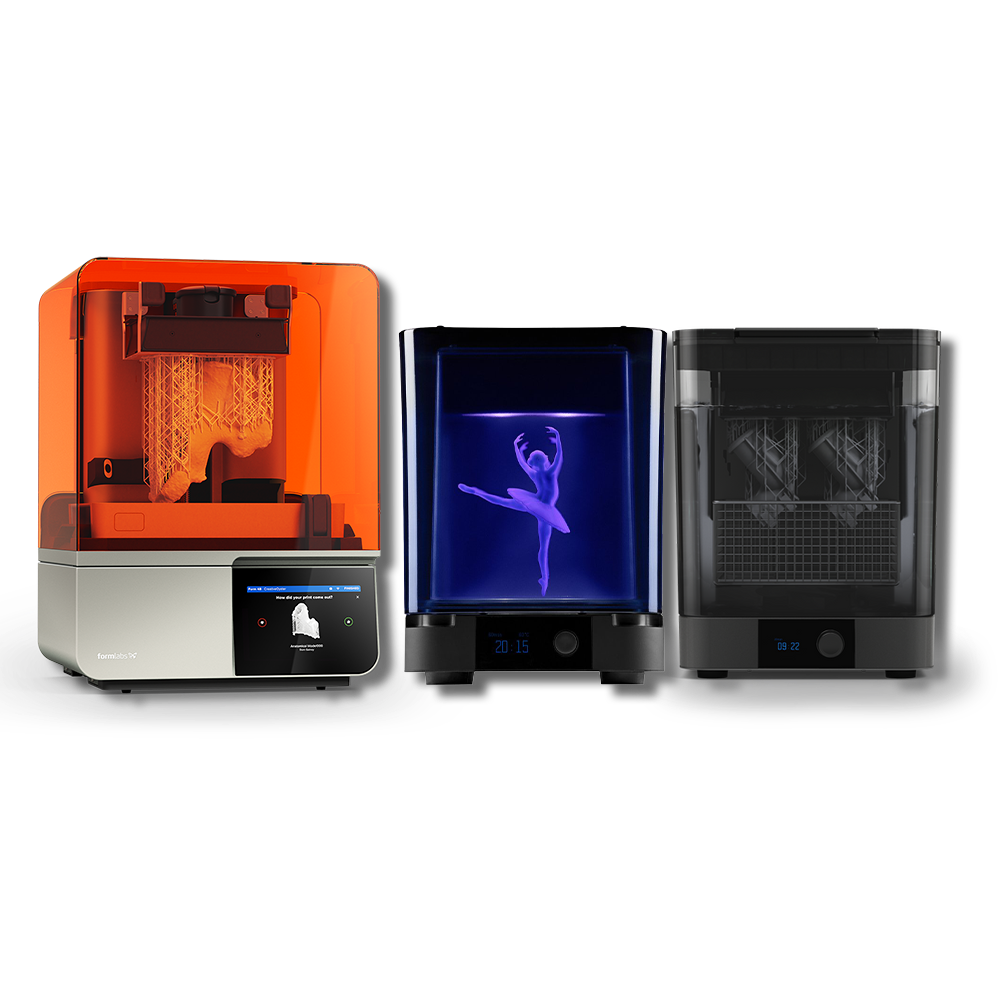

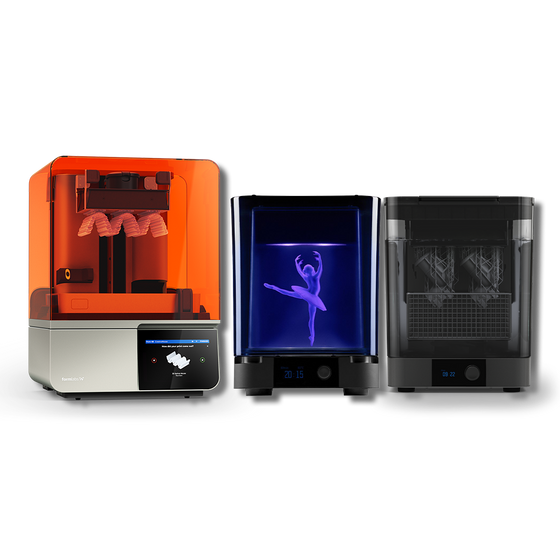

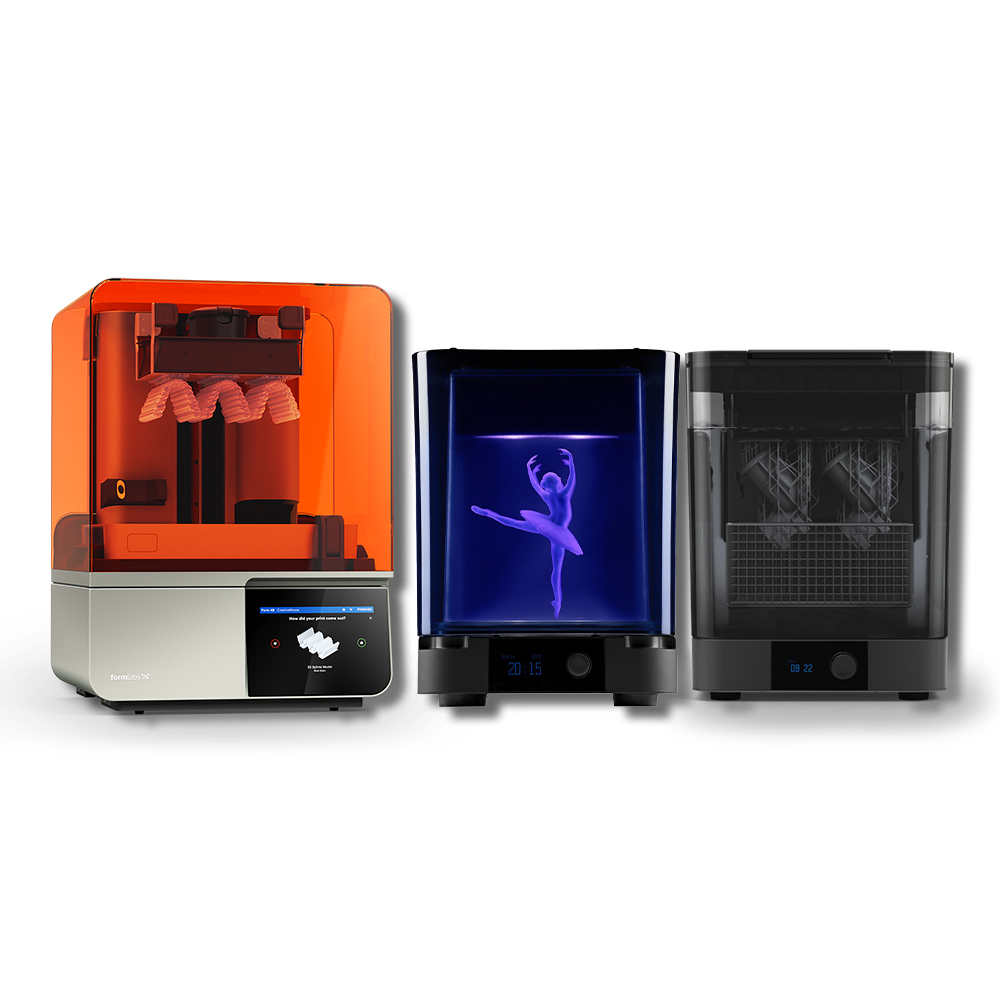

Each Fuse 1+ 30W selective laser sintering (SLS) 3D printer includes the essential tools required to start printing.

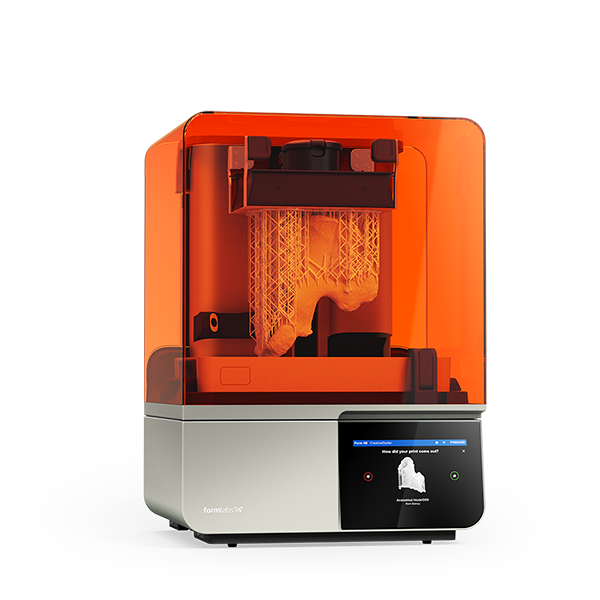

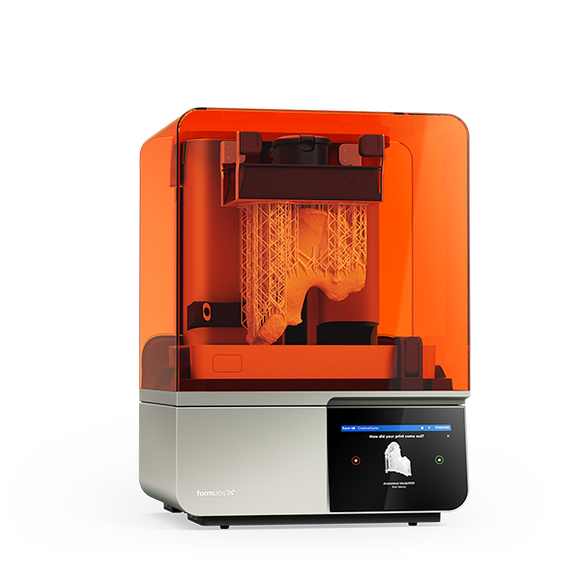

Bring production-ready nylon 3D printing onto your benchtop with an affordable, compact selective laser sintering (SLS) platform. The Fuse 1+ 30W delivers industrial power in a small footprint with effective powder containment and easy setup. From print setup to powder recovery, our easy-to-use hardware and software are designed to maximize your efficiency at every step of the process.

With final parts that combine strength, flexibility, and detail, Fuse 1+ 30W prints are ready for rigorous functional testing, or to ship ready-to-use products to customers.

Main Features

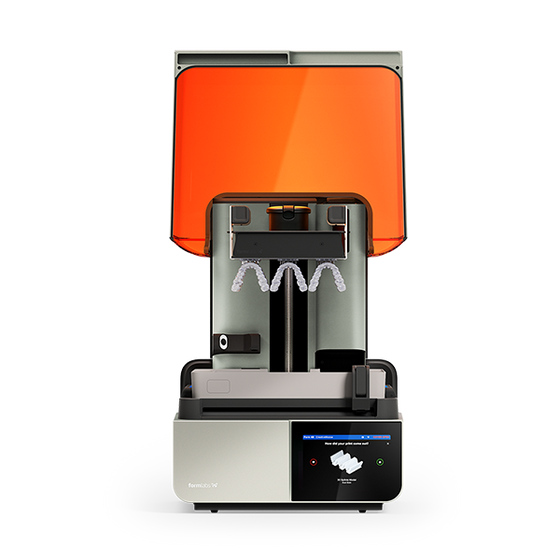

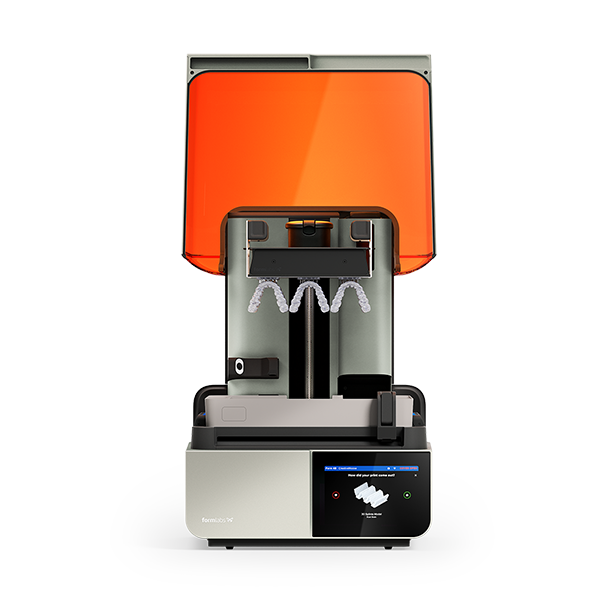

SLS, made manageable from wherever you are.

During setup and printing, an intuitive Touch UI walks you through every step.

The touchscreen displays a live stream of the print bed so you can watch each new layer take shape. This camera view is also available from your computer in PreForm so you can monitor your print without leaving your desk.

Take control of your production across multiple locations and machines. Track print jobs and material flow all in one cloud-based Dashboard to ensure minimum downtime and maximum output.

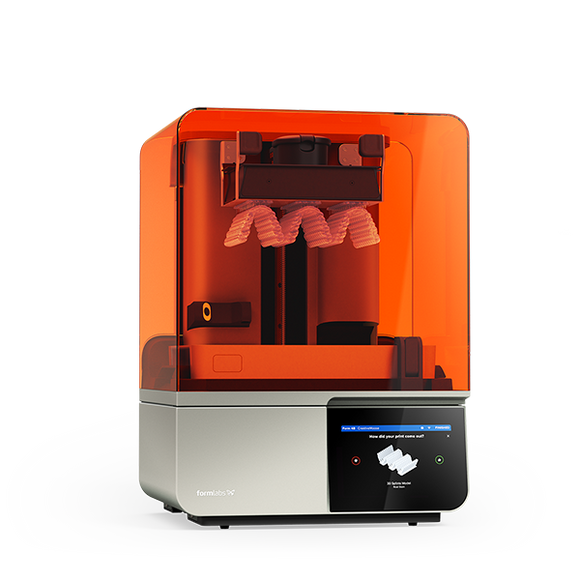

Reliable, consistent printing.

SLS 3D printing fuses powder layer by layer. The unused material supports the parts during printing so you can create complex, interconnecting designs with no need for support structures. Patent-pending Surface Armor technology creates a semi-sintered shell around the surface of each part, enhancing mechanical properties and surface quality without the hassle of a large, industrial footprint. These qualities are heightened even further when using the inert gas print option available with Fuse 1+ 30W.

Designed for 24/7 throughput.

Achieve faster-than-ever printing speeds to deliver prototypes and small series of end-use parts in under 24 hours. Enable continuous throughput by adding a second, removable build chamber to any Fuse Series workflow. Industry-leading rapid cooldown times allow you to start a new print within 1-2 hours of your previous print job.

Strong, Functional SLS Materials

3D print production-ready, end-use parts with our family of SLS Powders, developed specifically for the Fuse Series printers. Our materials, hardware, and software are developed and validated together to deliver peak performance while optimizing cost per part. Benefit from enhanced mechanical properties and higher powder recyclability when utilizing Fuse 1+ 30W's inert gas atmosphere print option. Available now: Nylon 11, Nylon 12, Nylon 12 GF, and Nylon 11 CF Powders. Stay tuned for regular releases of exciting, new materials currently in development.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.