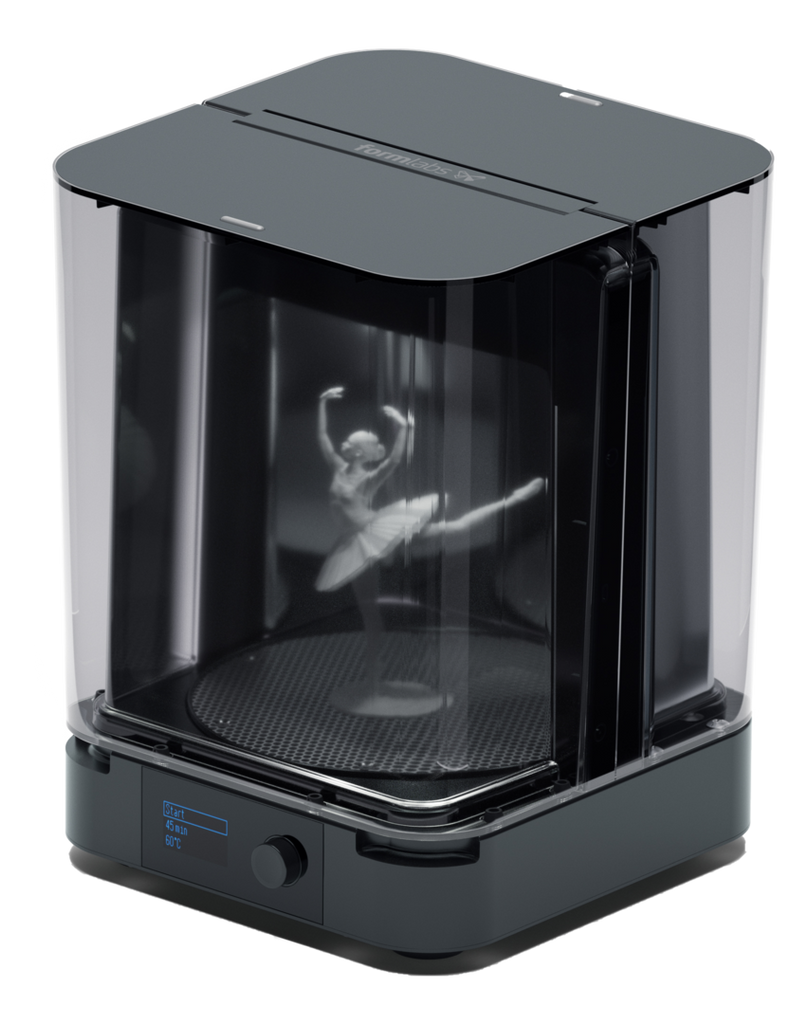

Reliable, Professional Post-Curing

Form Cure is finely tuned to bring parts to their maximum mechanical properties. Once the time is up, parts are fully cured and ready for peak performance.

Technical Data Sheet

- Printer Compatibility: Form 3, Form 2, Form 4

- Dimensions: 26.2 x 26.2 x 34.0 cm (10.3 x 10.3 x 13.4 in)

- Height when open: 64 cm (25.2 in)

- Weight: 5.6 kg (12.4 lbs)

- Turntable Diameter: 19.3 cm (7.6 in)

- Maximum Part Size: 14.5 × 14.5 × 17.5 cm (5.7 x 5.7 x 6.9 in)

- Suggested Operating Environment: 18-28 °C (64-82 °F)

-

Power Requirements: 90–240 V

6.0 A 50/60 Hz

144 W

-

80 DEGREES CELSIUS

An advanced heating system precisely controls curing temperatures up to 80 °C -

405 NANOMETERS

13 multi-directional LEDs emit the optimal wavelength of light for curing Formlabs materials -

1 REVOLUTION PER MINUTE

A rotating turntable provides uniform exposure during post-curing

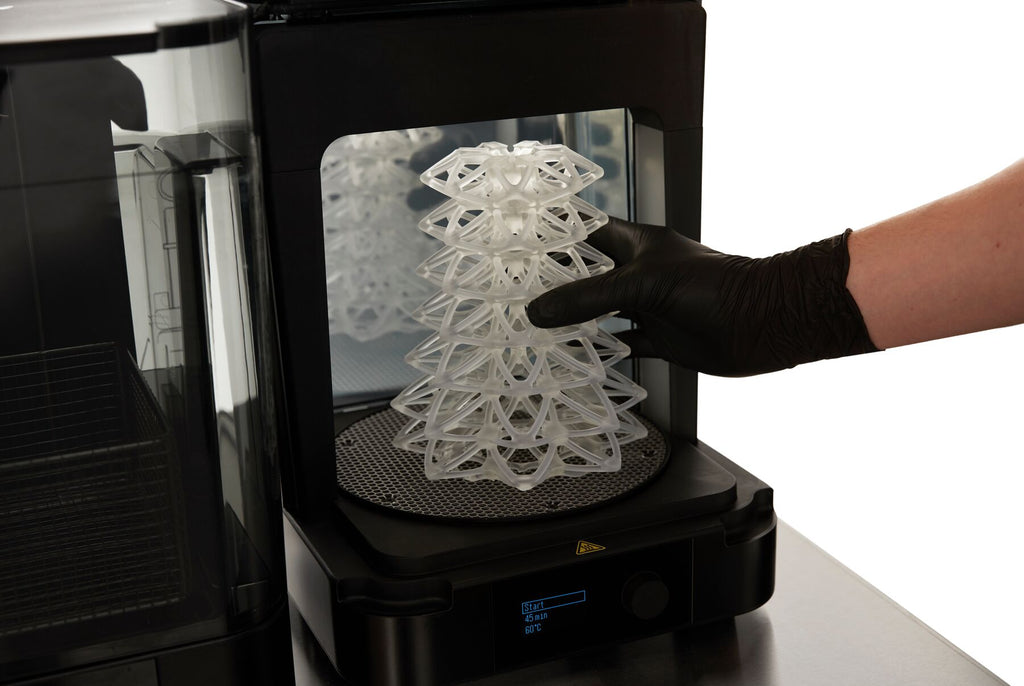

Built to complete the stereolithography (SLA) engine, Form Wash and Form Cure streamline your 3D printing process to produce better results with less time and effort.

Maximum Mechanical Properties with Form Cure

- Advanced Heating: Precise heat control is the key to successful post-curing. Form Cure’s chamber is able to achieve temperatures of up to 80 C.

- Balanced UV Light: 13 LEDs use 405 nm Light to trigger the post-curing reaction, working with the heater to post-cure parts.

- Uniform Exposure: A rotating turntable, heat flow, and dispersed lights provide uniform exposure during post-curing.

- An Intuitive Interface: It’s easy to set Form Cure’s temperature and post-cure time. For Standard Resins, simply use the default. For all other materials, use recommended settings for optimum performance.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.