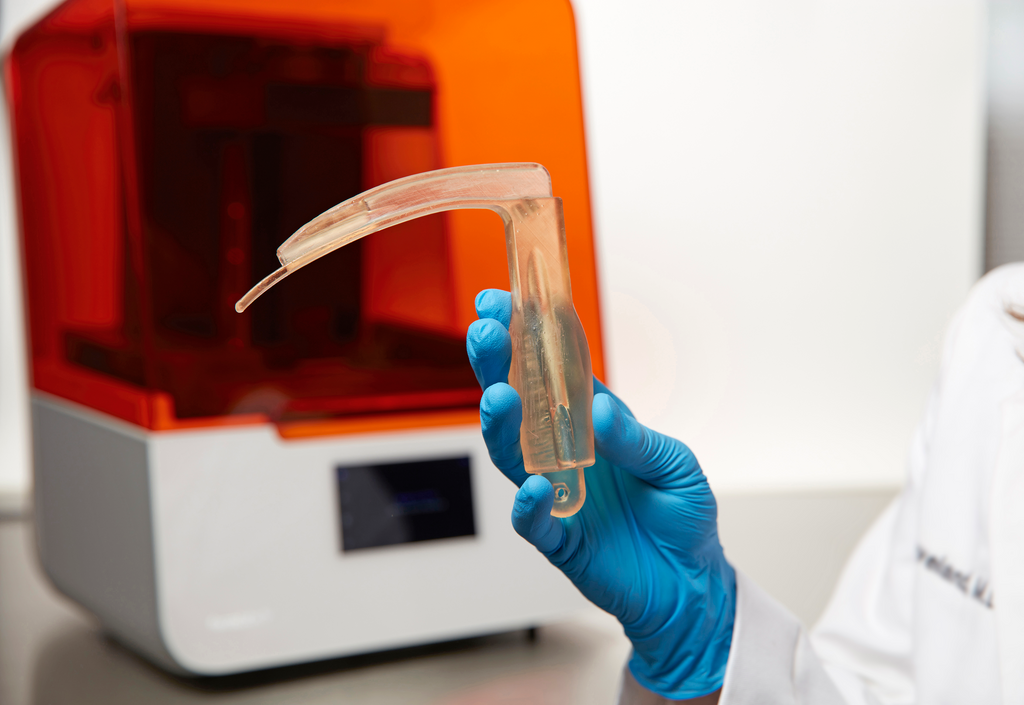

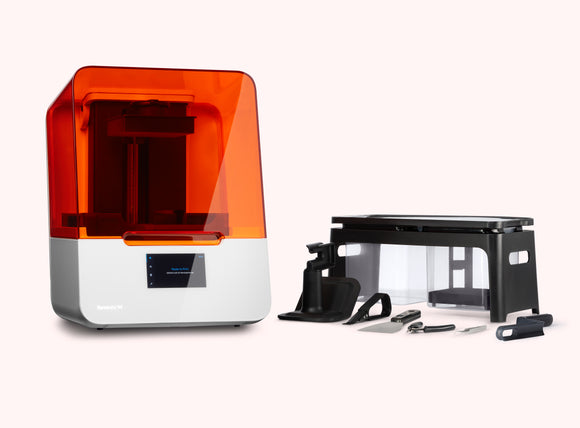

This product is exclusively for use with the Formlabs Form 4B

This resin requires post curing

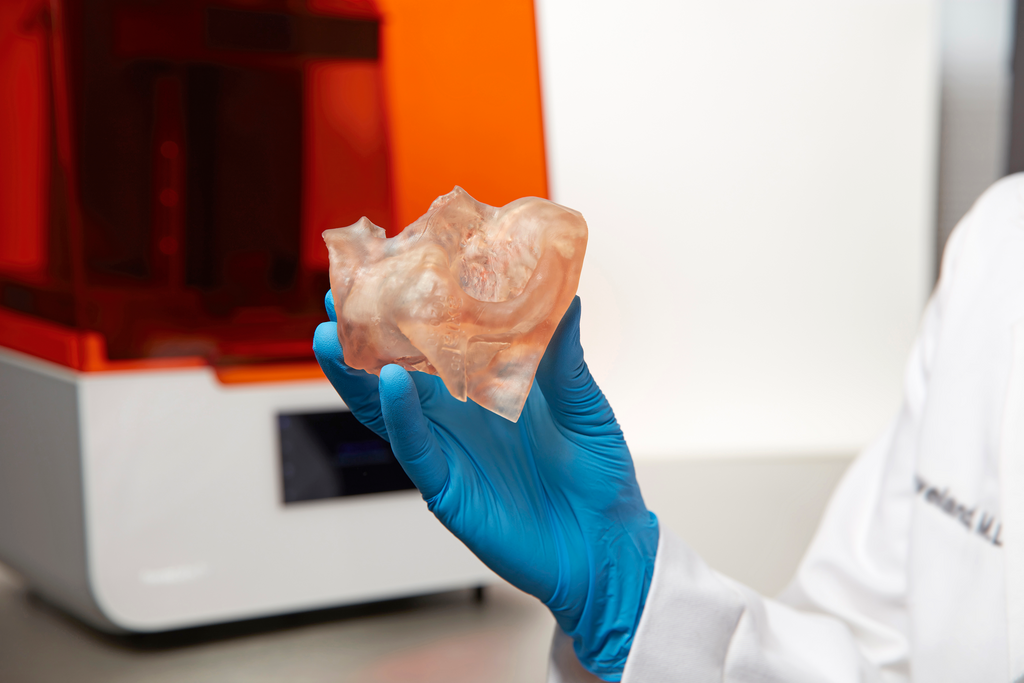

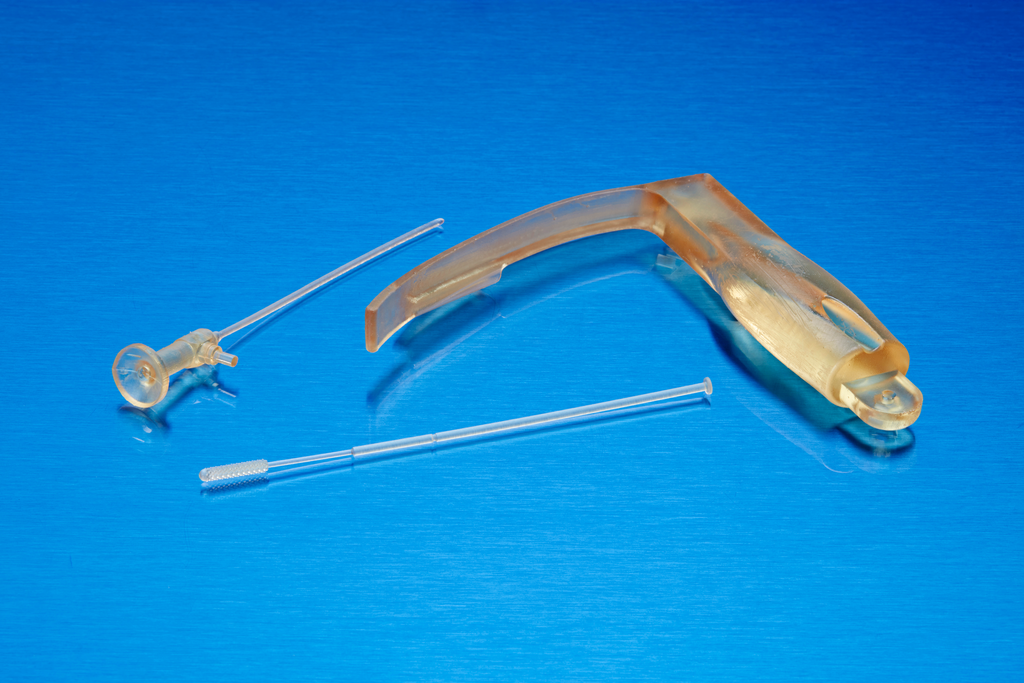

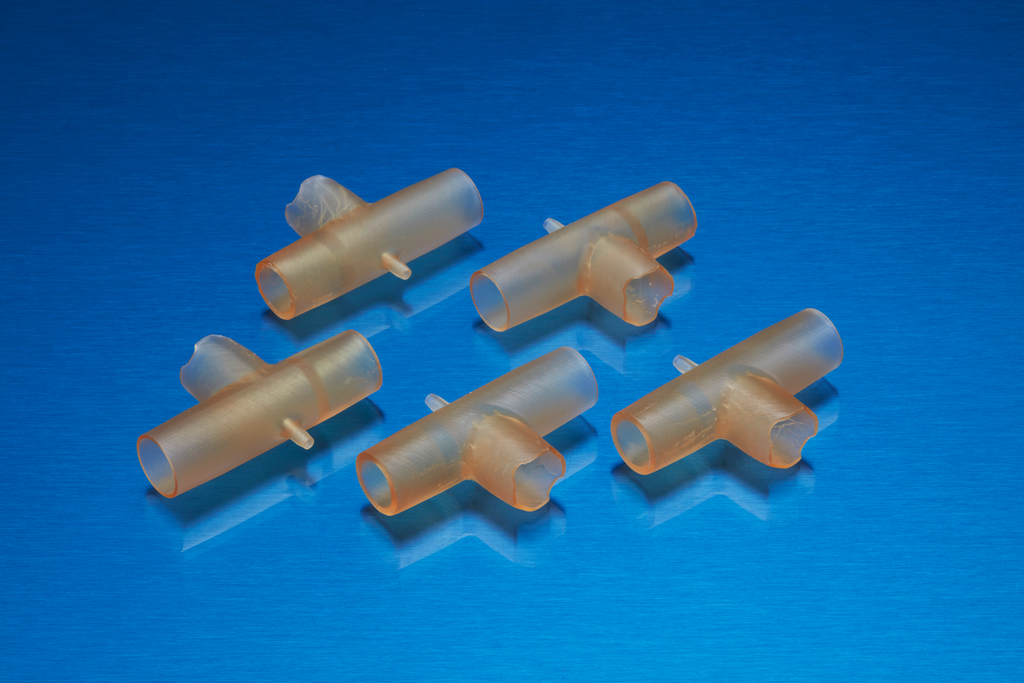

BioMed Amber Resin is designed for the manufacture of biocompatible 3D printed parts with high dimensional accuracy, stiffness, and strength. This material is developed specifically for Formlabs printers, rigorously tested, and manufactured in a clean room at our own ISO 13485 certified facility for consistent cross-batch quality. The parts printed with BioMed Amber Resin are compatible with common solvent disinfection and sterilization methods.f

- Ultimate Tensile Strength: 73 MPa - 11 ksi

- Young’s Modulus: 2.9 GPa - 420 ksi

- Elongation: 12.3%

- Flexural Strength: 103 MPa - 15 ksi

- Flexural Modulus 2.5 GPa - 363 ksi

- Hardness Properties: Hardness Shore 67D

- 1 Litre of Formlabs BioMed Amber Resin (OEM)

- Wash for 20 minutes in Form Wash

- Air dry at room temperature for at least 30 minutes

- Inspect part to ensure it is clean and dry with no residual resin, IPA, or particles on the surfaces

- Chemical Disinfection - 70% Isopropyl Alcohol for 5 minutes

- Steam Sterilization: Autoclave at 134 °C for 20 minutes or Autoclave at 121 °C for 30 minutes

BioMed Amber Resin was tested at NAMSA World Headquarters, OH, USA.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.