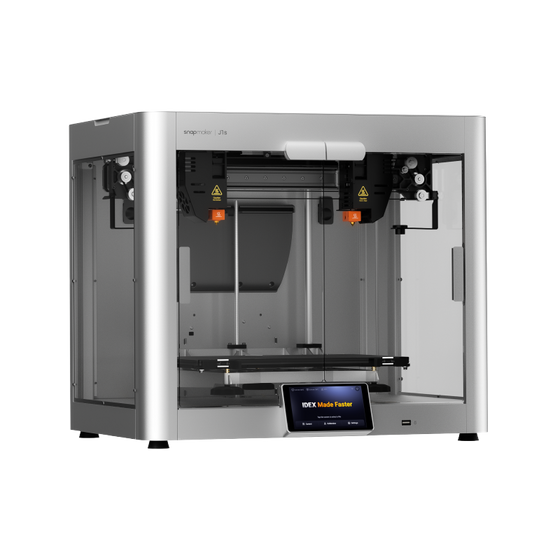

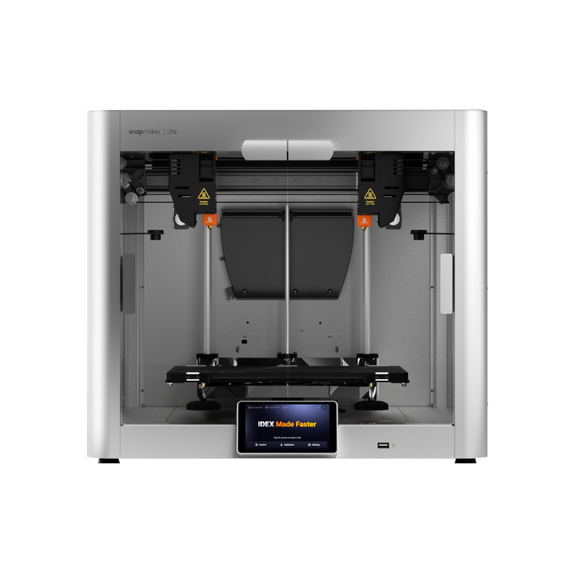

- Newly designed Linear Modules

- Newly designed 3D Printing Module

- Newly designed Power Module with intelligent fan speed adjustment

- 1600mW Laser Cutting Module with built-in camera

- CNC Carving Module with ER11 Collet

- Controller powered by Cortex-M4 Processor

- 5" Smart Touchscreen (Android OS, Quad Core A7 CPU @ 1.1GHz)

- Magnetic Heated Bed with removable Print Sheet for 3D Printing

- Aluminum Grid Table for Laser Engraving and Cutting

- MDF Board & Clamp Sets for CNC Carving

- Free 3-in-1 Software: Snapmaker Luban

- Materials including 1kg spool of PLA filament, 2 pcs of laser material, and 1 pc of CNC material

Frame Material: Aluminum alloy

Data Transmission Methods: Wi-Fi, USB cable, USB flash drive

Rated Power: 320 W

Dimensions (W x D x H)

495 x 506 x 580 mm

3D Printing

Work Area (W x D x H): 320 x 350 x 330 mm

Max Heated Bed Temperature: 80°C

Layer Resolution: 50-300 microns

Nozzle Diameter: 0.4mm

Max Nozzle Temperature: 275°C

Laser Engraving and Cutting

Work Area (W x D x H): 320 x 350 mm

Camera: Built-in camera

Laser Power: 1600 mW

Wavelength: 450nm

CNC Carving

Work Area (W x D x H): 320 x 350 x 275 mm

Shank Diameter: 0.5-6.35 mm

Spindle Speed: 6,000-12,000 RPM

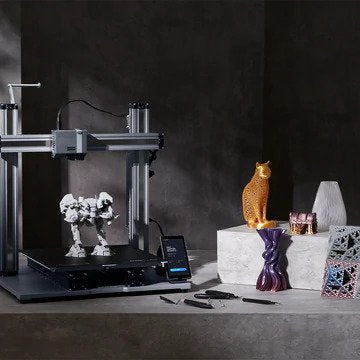

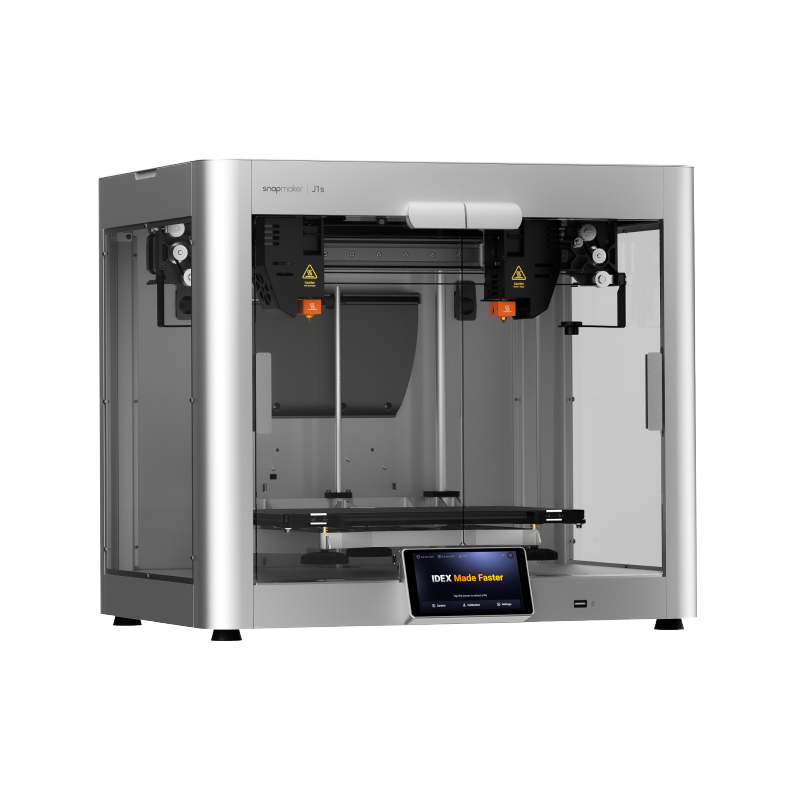

A POWERFUL AND EXPANDABLE MODULAR SYSTEM

Snapmaker 2.0 Modular 3-in-1 3D Printer (Snapmaker 2.0 hereafter) unlocks your full creative potential, from 3D printing to laser engraving, cutting, and CNC carving. Smarter, faster, larger, and more powerful than ever before, it is a new generation of 3-in-1 3D printer that comes with everything you need.

3D PRINTING

Snapmaker 2.0 is ideal for beginners who are just getting started, hobbyists who prefer more customized options, as well as engineers and designers who want to print large objects or accurate parts with outstanding print quality.

FILAMENT RUNOUT RECOVERY

Say goodbye to unfinished prints or "air printing". Equipped with a filament runout sensor, the machine will alert you when the filament has run out. You can now print large objects without breaking a sweat.

HIGH QUALITY AT 100 MM/S

Optimized motion control algorithm improves coordination between the extruder of the 3D Printing Module and Linear Modules driven by lead screws, alleviating under- or over-extrusion happening at the corners, which allows Snapmaker 2.0 to deliver excellent printing quality even at 100 mm/s.

FLEXIBLE PRINT SHEET

Removing a print is now easier than ever. Just lift and flex the sheet, and your print will come right off. You can snap the print sheet back onto the magnetic heated bed in an instant.

AUTO LEVELING

The proximity sensor probes and obtains data for specific points on the heated bed and the machine compensates automatically for microscopic irregularities, thus enabling a nice and even first layer, which is a prerequisite for a successful print. Just a few taps, and witness all the intelligent work done.

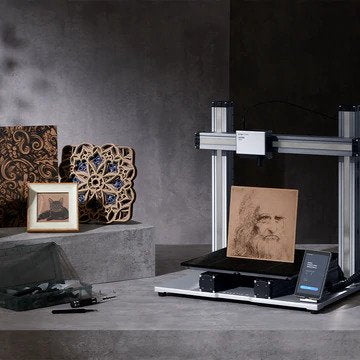

LASER ENGRAVING & CUTTING

Traditional 3D printers can only 3D print. Snapmaker 2.0 does more. With interchangeable modules, Snapmaker's functions can be changed quickly, just like changing lenses on a camera. Now you can make beautiful and artistic creations using laser engraving and cutting.

CNC CARVING

You can even use Snapmaker 2.0 as a CNC router to create complicated 2.5D and 3D objects. It has a more stable work speed and a much larger work area than Snapmaker Original, making it a perfect machine for you to start out on CNC carving.

0.2 MM × 0.3 MM LASER SPOT

Using a semiconductor laser as its light source, the laser module can engrave with a 0.2 mm × 0.3 mm laser focus, therefore making incredibly accurate images on various materials.

BUILT IN CAMERA

The built-in camera enables the Auto Focus and Camera Capture features, so that you will spend less time focusing the laser, and can edit your design and position it exactly where you want it to be. What you see is what you get!

ALUMINUM GRID TABLE

The aluminum structure not only allows the smoke to be fully exhausted, but also leaves enough space for laser penetration. It alleviates burn-in of the laser unit and excessive carbonization on the back of the material.

CUSTOM MDF PLATFORM AND CLAMP SETS

Each Snapmaker 2.0 comes with an MDF board and clamp sets. The board is removable and can protect other machine parts from damage, while the customized clamp sets offer a much easier and steadier fixation than before.

ER11 COLLET

The standard ER11 collet guarantees a better concentricity that allows for a more stable CNC carving speed and larger step-down. It also supports over 100 CNC bits, whose diameters range from 0.5 mm (0.02") to 6.35 mm (0.25").

DUST RESISTANCE

The leadscrew, driver chip, and precision parts of the Linear Modules are completely enclosed in the aluminum alloy housings, which eliminates dirt accumulation and ensures better durability.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.