Fromlabs Fleet Control will now be free for Form Auto users.

You Must Own a Formlabs Build Platform 2 In Order To Use The Formlabs Form Auto

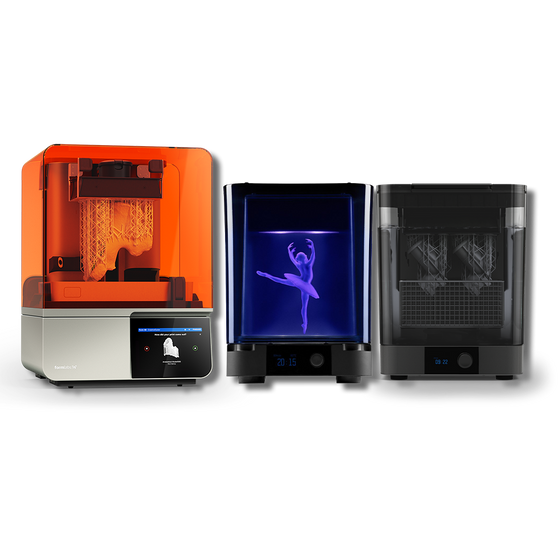

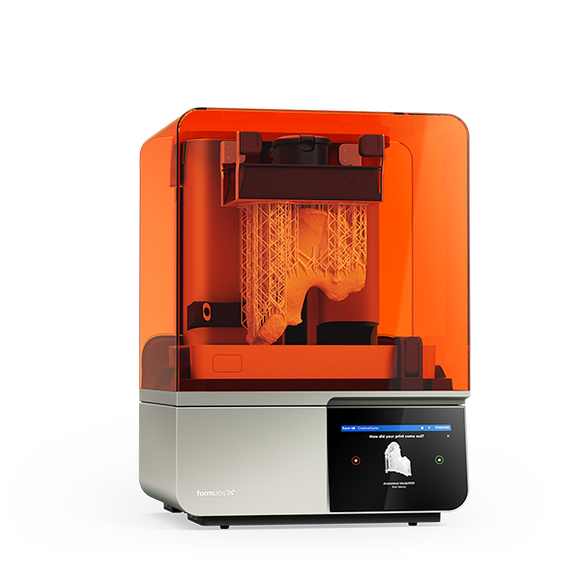

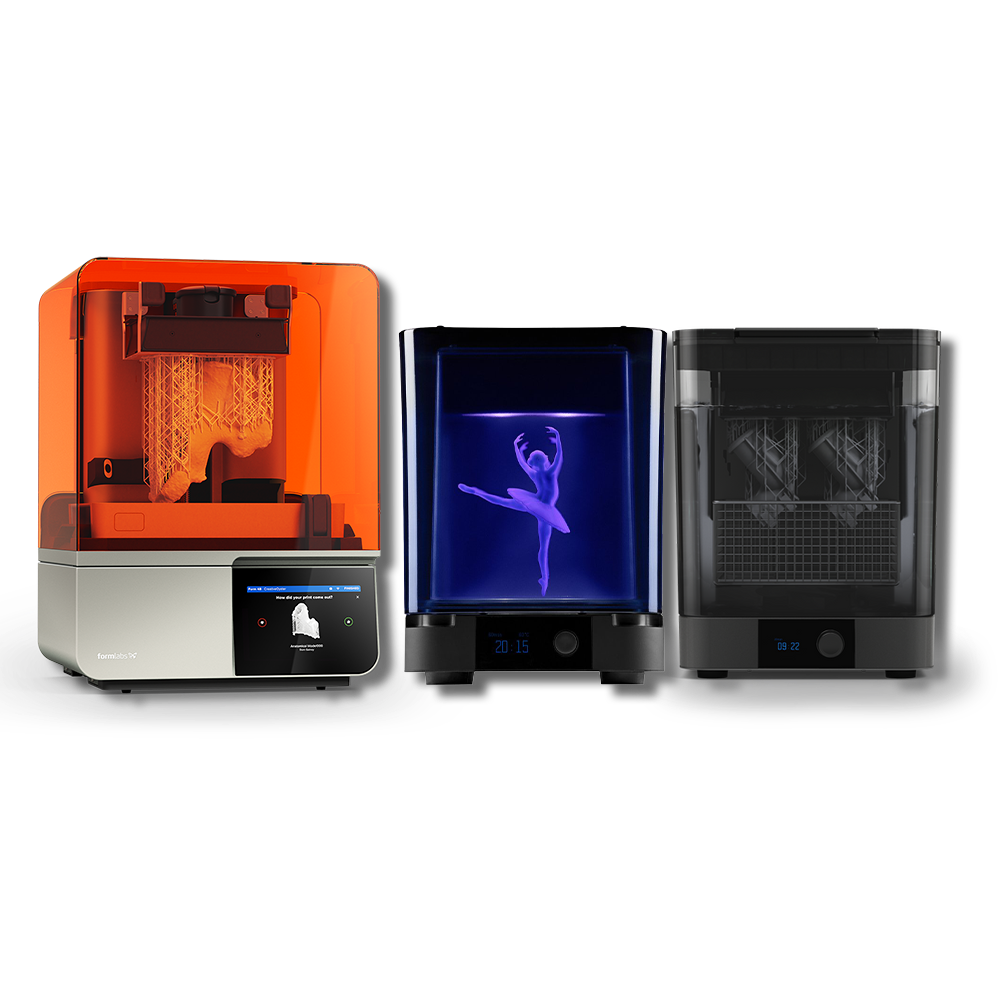

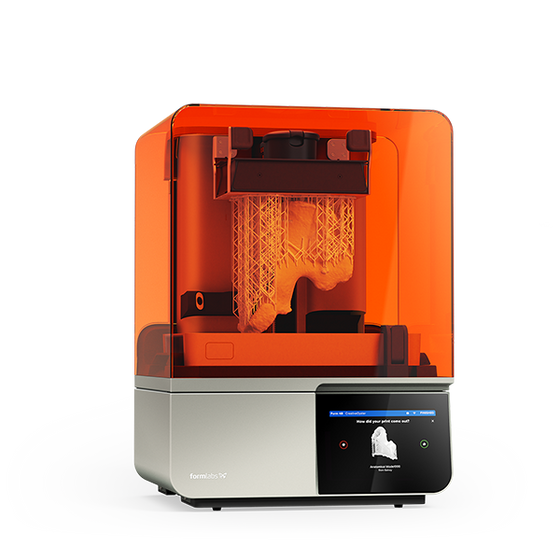

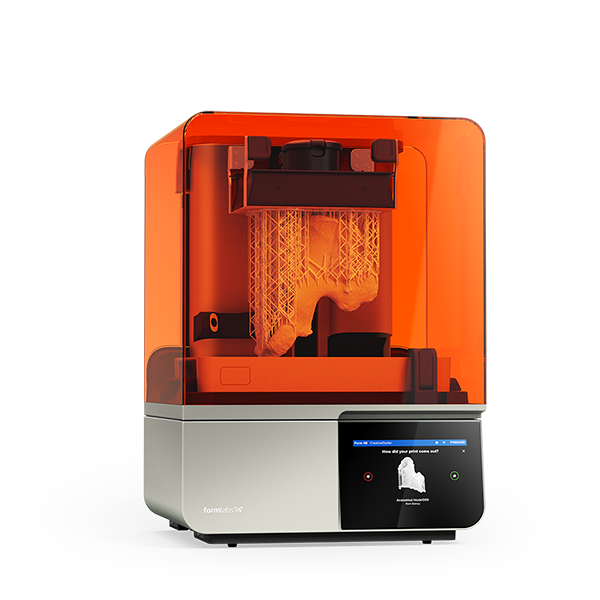

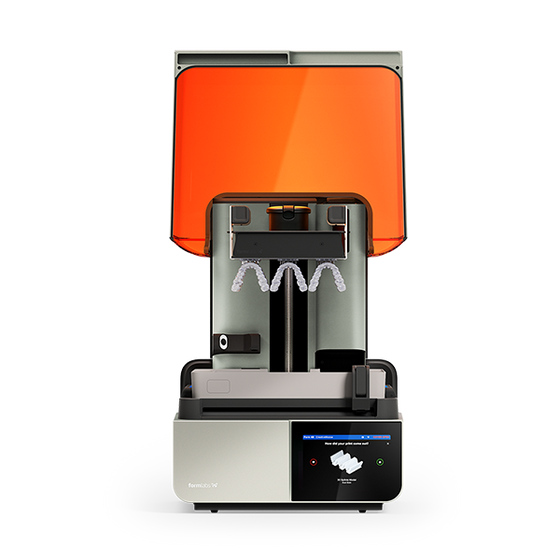

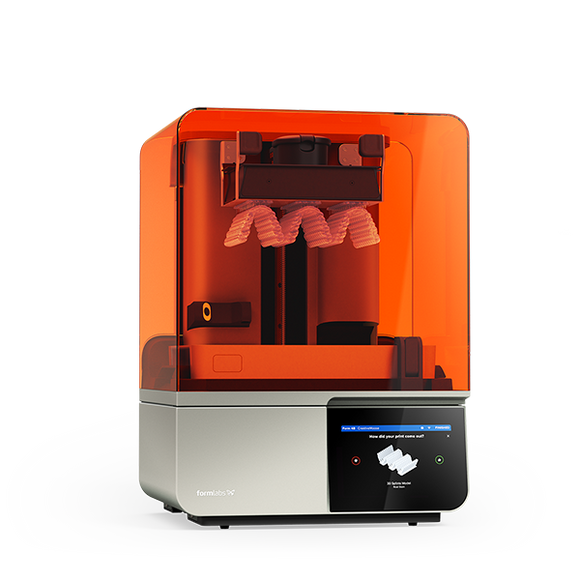

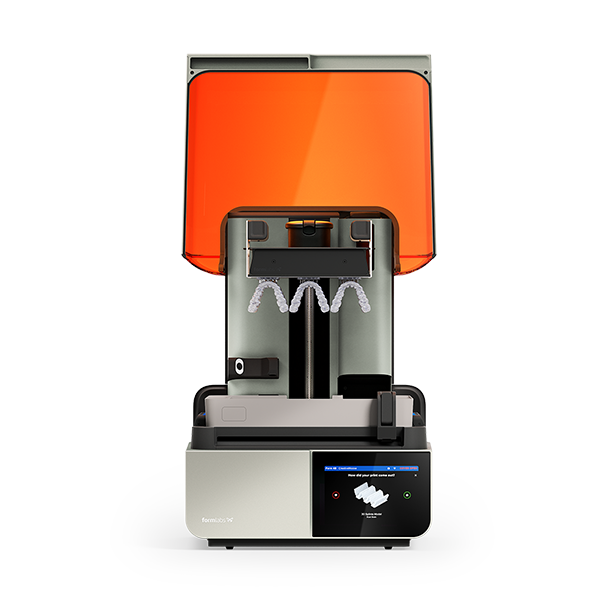

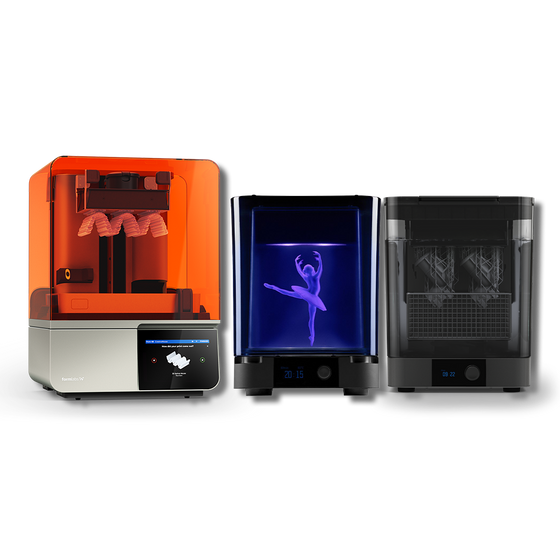

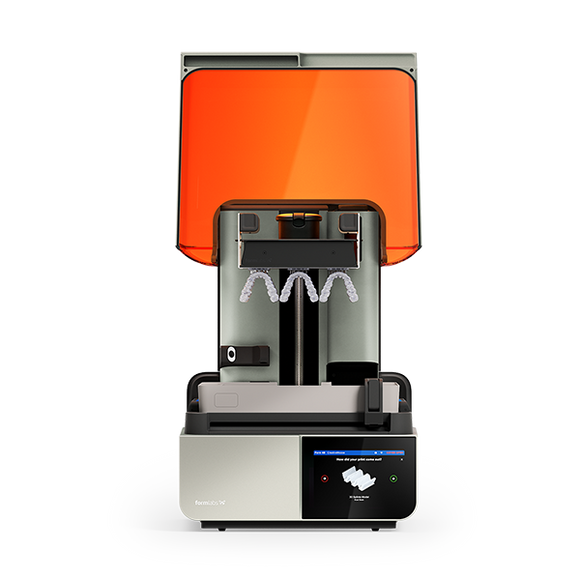

Form Auto is a hardware extension for the Form 3+ and Form 3B+ Series 3D printers that automatically removes finished parts from Build Platform 2 and starts the next print without the need for operator interaction, enabling 24/7 3D printing with no printer downtime.

-

Form Auto:

Instantly automate any new or existing Form 3/B/+ 3D printer with a hardware extension that will automatically remove finished parts and start the next print for back-to-back production. -

Fleet Control:

Simplify multi-printer management with a suite of new, advanced features in Dashboard including centralized queue management and automatic printer assignment. -

High Volume Resins System:

Continuously print on a Formlabs SLA printer for five times longer with the seamless delivery of 5L of resin through a pumping system.

Skyrocket Your Ability to Produce High-Quality and Affordable Parts with Automated 24/7 3D Printing

Reduce cost per part with autonomous 24/7 printing on your Form 3/3+ 3D printer. Form Auto runs back-to-back prints which redefine your idea of throughput:

Grey Resin

36/ per day

With Form Auto

$1.87

Without Form Auto

Start Scaling Your Production Now

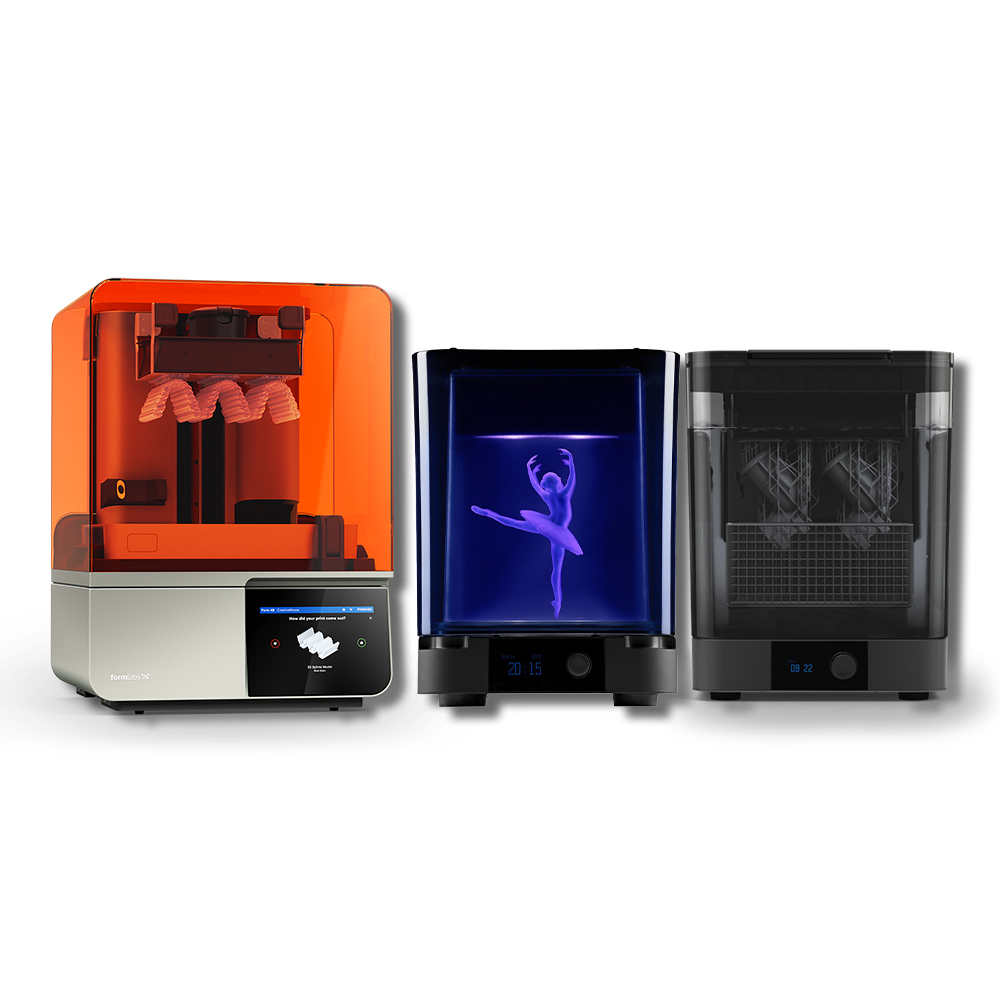

Work more efficiently and redefine production capacity in your 3D printing workflow with Formlabs Automation Ecosystem including Form Auto, Fleet Control, and the High Volume Resin System.

Scale your part production without increasing printer management complexity. Hit send from anywhere and the Formlabs Automation Ecosystem will take care of the rest.

Minimize Cost Per Part with Labor Savings Up to 80%*.

Form Auto works overtime so you don’t have to. Before Form Auto, every completed part required manual removal from the build platform before post-processing. Form Auto fully automates part removal by leveraging Formlabs patented Quick Release Technology with Build Platform 2. Collected parts are placed in a UV-safe container for seamless batch transfer to the Form Wash. Instantly automate your printers without additional training. Form Auto works with any Form 3/3+ 3D printer out in the field or purchased today, so you can level up your production at any time. * Calculation based on dental arches printed in Draft Resin at 200µm.

24/7 3D Printing, With No Interaction Required.

Never let a printer sit idle with prints waiting in the queue. Form Auto is always ready to start the next print with or without an operator on-site. Build multi-print queues from anywhere, at any time. Click ‘Print’ from the office, and instantly start production on the manufacturing floor. Monitor and review finished parts remotely via images and videos in Fleet Control. An onboard camera saves a record of each part by capturing each print as it completes.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.