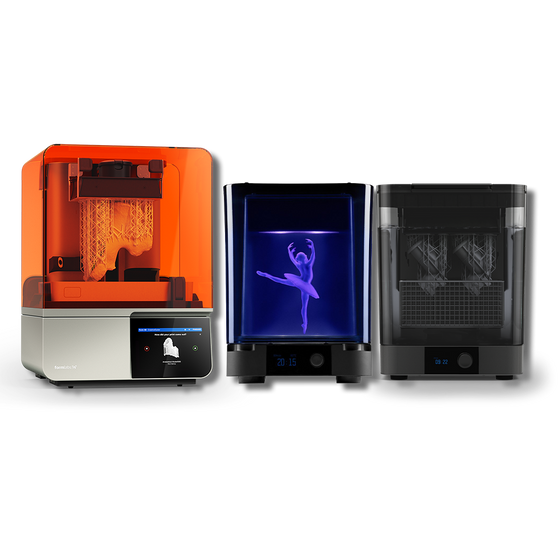

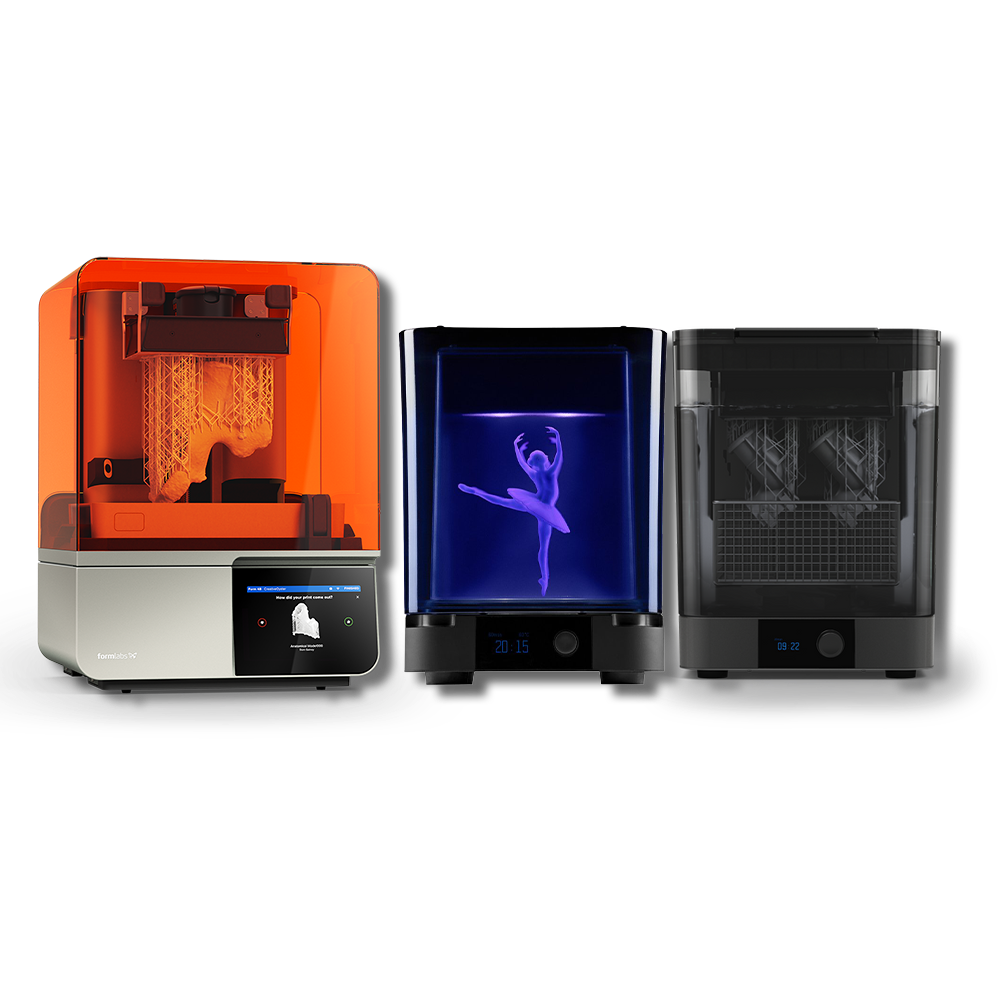

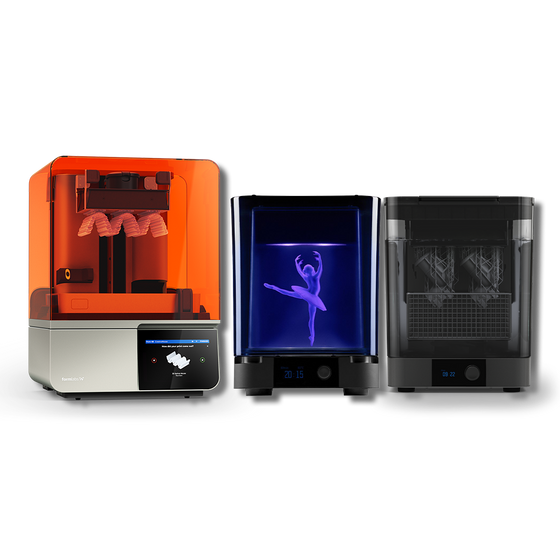

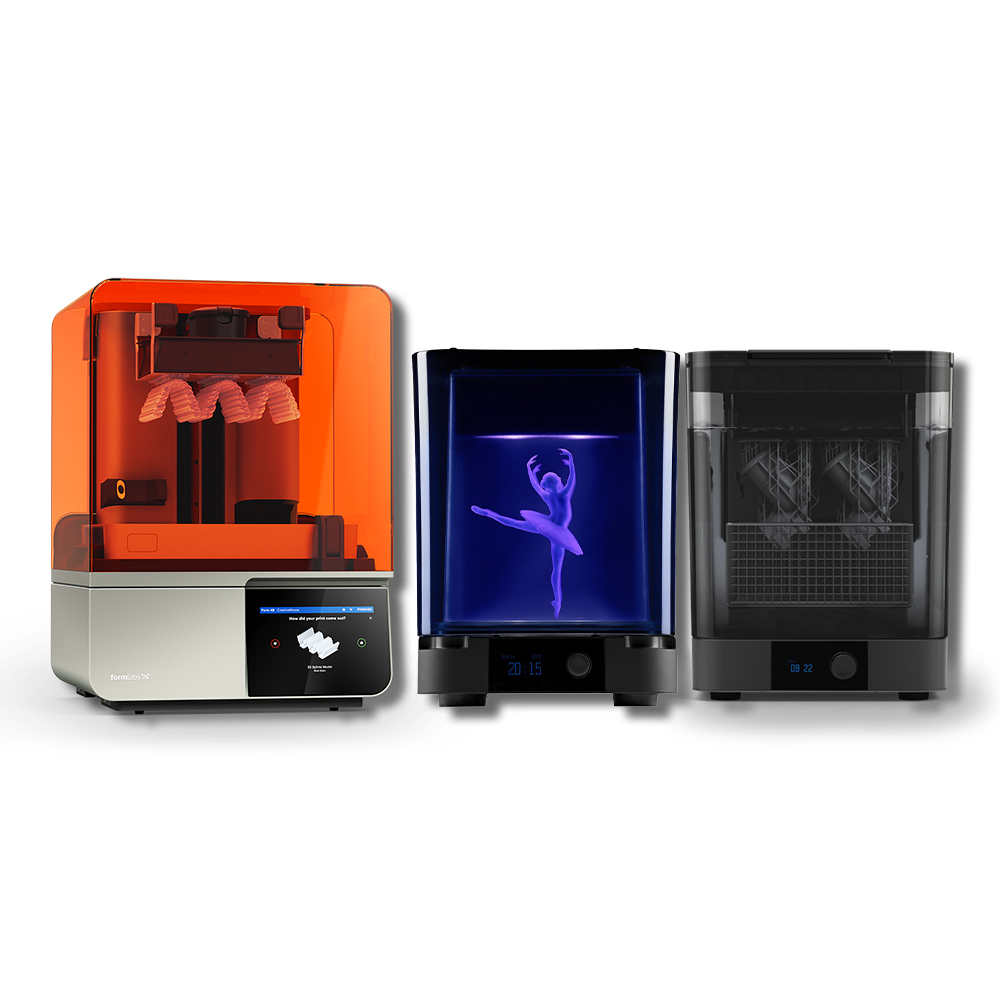

The Form 3 & 4 are a part of a 3D printing ecosystem that’s easy to learn and use and requires little intervention or maintenance. The Form Wash L V2 agitates and soaks 3D printed parts in solvent (IPA, TPM) and then removes them from the bath to dry. The Form Cure L V2 exposes 3D printed parts to the appropriate levels of light and heat to optimize material properties.

- Form 4L

- Form 4BL

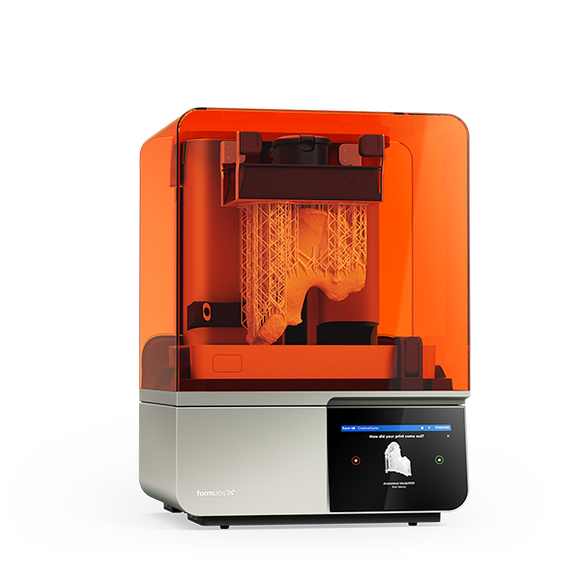

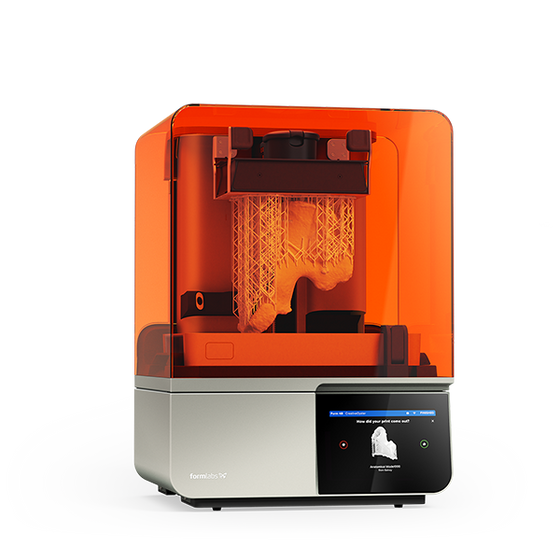

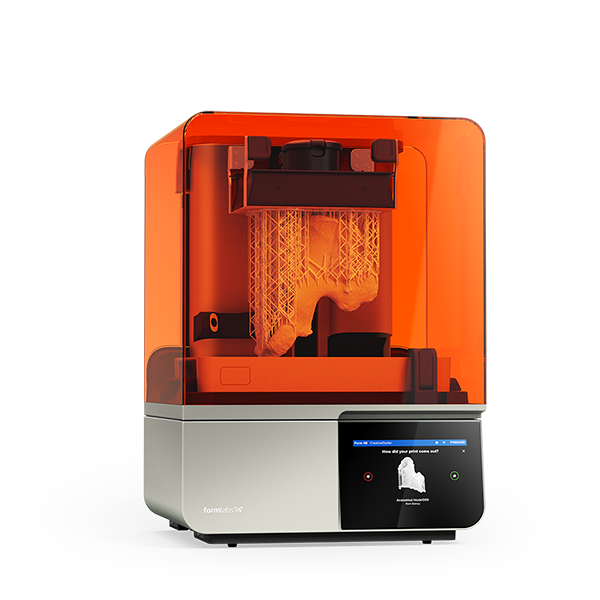

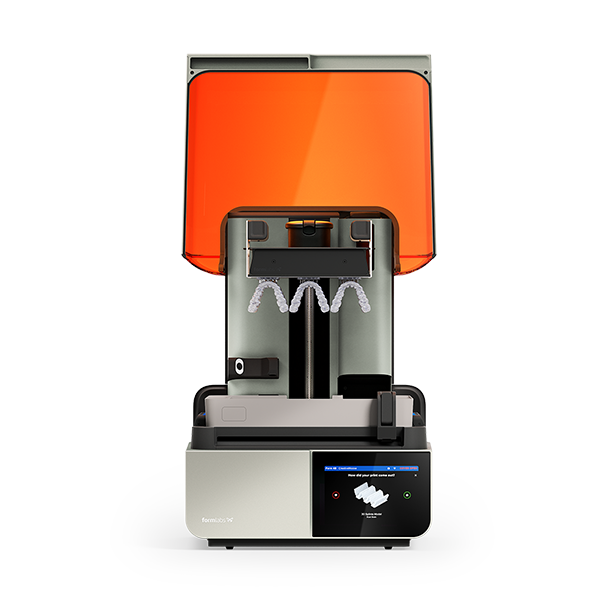

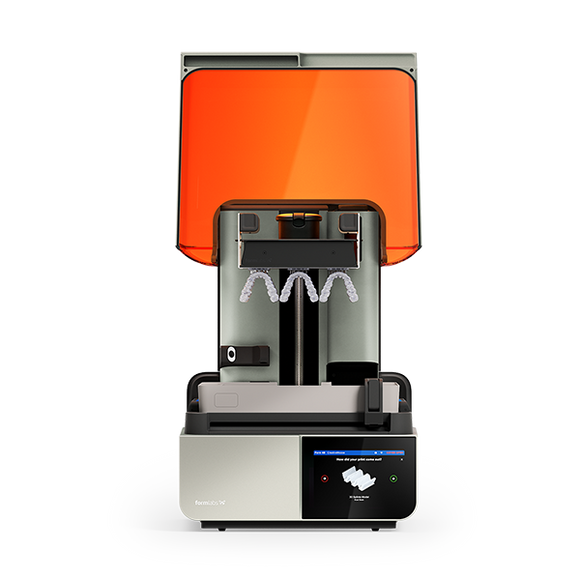

- Form 4

- Form 3L

- Form 3BL

- Form 3

- Form 3B

- Form 2

- Form Cure L V2

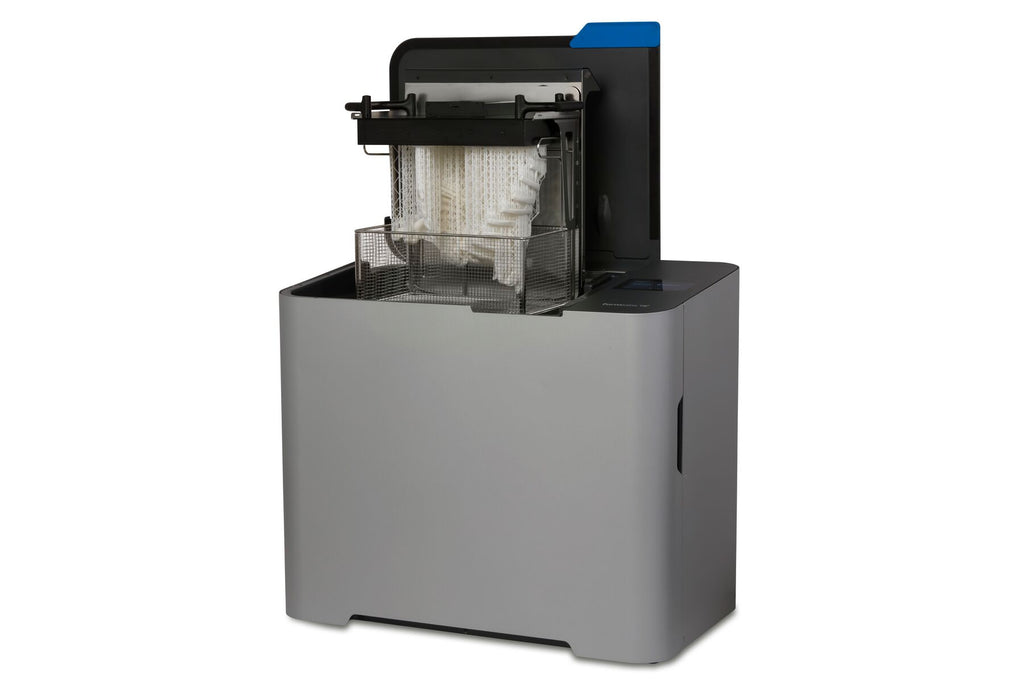

- Form Wash L (2nd Gen)

- Build Platform Adapter

- Solvent Pump

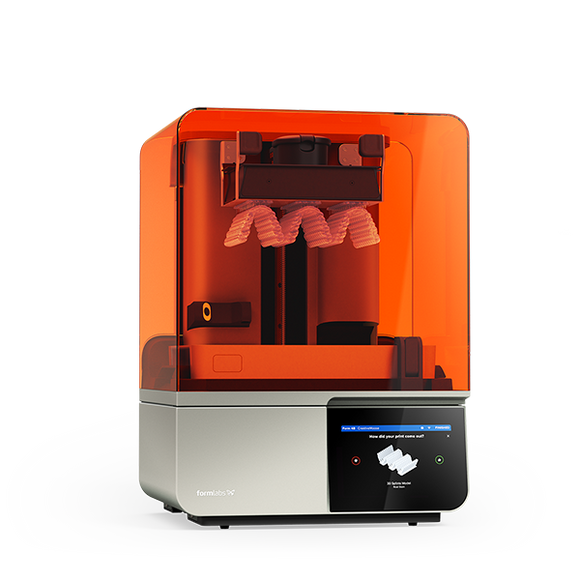

Form Cure L V2 precisely combines heat and 405 nm light to deliver tough, strong prints with unprecedented speed and consistency. Now you can post-cure large Form 4L/BL prints in as little as 60 seconds, with 5x more UV power, faster heat-up times, and a 26% reduction in overall footprint from the previous generation while curing up to 19% larger parts. To begin curing, just select a validated preset for Formlabs 45+ materials. Advanced users can customize time and temperature to fit their specific needs.

Post-curing completes the chemical reaction started during printing, enhancing final part strength, toughness, heat resistance, and creep resistance while creating a harder, less tacky surface.

For biocompatible materials, post-curing is necessary to achieve the safety standards determined by regulatory agencies.

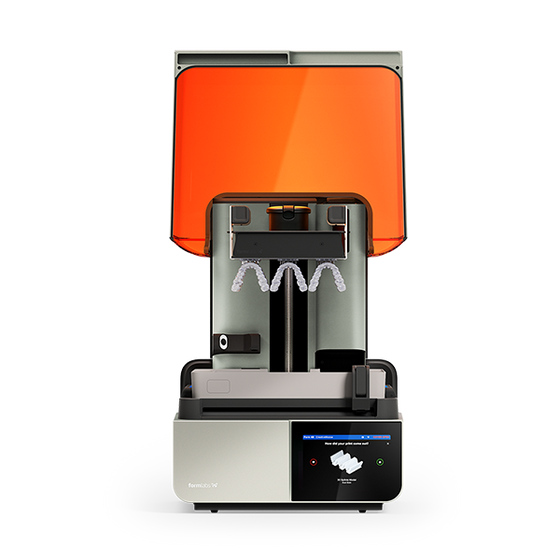

All SLA 3D printed parts require washing to remove residual resin. Form Wash L automates this process, leaving you with smooth, clean, high-quality parts every time.

Once washing completes, parts are lifted out of the solvent to air dry, avoiding over-soaked, warped prints. The embedded solvent monitor helps you maintain peak cleaning performance by notifying you when it’s time to replace your solvent.

Use Form Wash L with all of your Formlabs SLA 3D printers. Wash one Form 4L build platform or two Form 3/4 build platforms with the included build platform adapter.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.