New Formlabs 2000 Resin | The lowdown on Tough and Durable Resin Family

March 19, 2020

First let's cover why Tough 2000 was created and the main pain-points of Tough V5, then we'll see how it fits with the Tough and Durable resin family along side Tough 1500, and Durable.

Why change Tough V5?

Through many customer testimonials about Tough V5, we found that it is too brittle to work in applications requiring ABS-like properties. It broke on impact and under mild bending stresses which made it difficult to prototype and work with.

We have also found that the bright blue colour was too distracting and off-putting in assemblies.

Lastly, the HDT or heat deflection temperature of the Tough V5 resin was also poor and under only mild hot temperatures (like on manufacturing floors), parts started to deform.

The latest resin from Formlabs is called Tough 2000, it is meant to improve and replace Tough V5 and open the door for more applications.

How is Tough 2000 better than V5?

In point form:

* New dark grey colour looks more professional than the bright blue and doesn't blend in with the Tough 1500 grey colour

* Improved HDT

* Improved strength, stiffness and elongation

The material scientists at Formlabs decided to scrap the old Tough V5 formula and start fresh with a complete reformulation while using knowledge gained when developing the Rigid and Elastic resins.

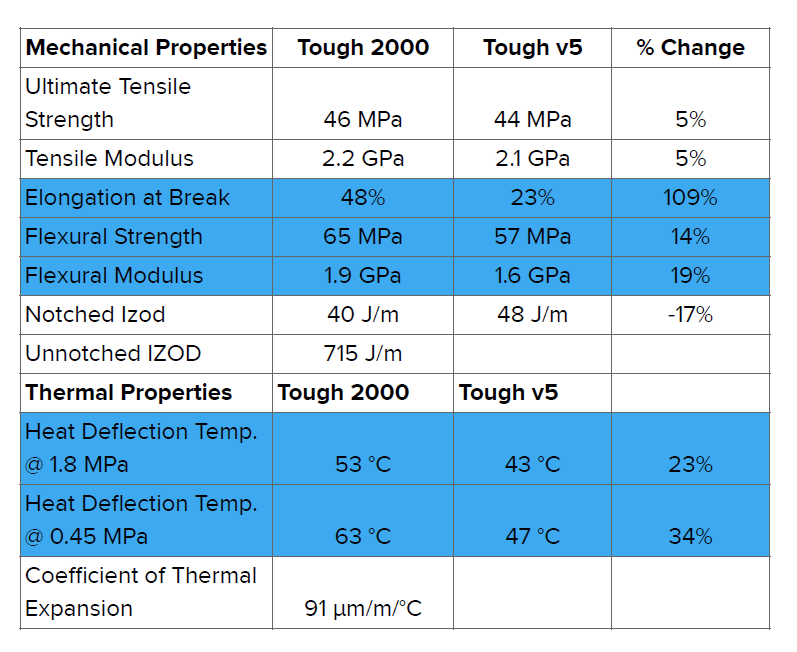

Here's a side by side comparison of Tough 2000 and Tough V5:

You can see that Tough 2000 has improved in every single way compared to Tough V5 on properties that are generally competing with each other. Polymer material science is pretty cool that way!

The new landscape of the Tough and Durable family

In order of most stiff to least stiff we now have the Tough 2000 at the top followed by Tough 1500 and then Durable resin. To paint a better picture of the family check out this table. It lists the resins in an order that makes sense with an arrow that tells which way the specific mechanical property increases or decreases.

This might still be confusing so here is another way to look at the Tough and Durable family:

These are material that are found in the wild all around you. ABS is the main plastic used in cars, your plastic containers are probably made out of PP and we hope you use soap from time to time!

Notes about printing and curing with the new Tough 2000

| Form 2 | Form 3 | |

| Resin tank compatibility | LT Tank | V2 Tank |

| Layer height | 50, 100 microns | 50, 100 microns |

| Form wash time | 10min + 10min | 10min + 10min |

| Form cure time | 70min @ 60C | 70min @ 60C |

Summarizing

The new naming convention and the new Tough 1500 and 2000 resins make selecting the correct material for an application way easier and more intuitive than before. You can simply look at a material name and know how stiff it is compared to others. As more new resins come out in the future, we'll see this naming convention becoming increasingly important.

Pre-order your cartridge here.

Also in News

Shop3D.ca at ADM Toronto (Advanced Design & Manufacturing Expo)

September 23, 2025

Shop3D.ca, Canada’s leading provider of 3D printing solutions, is proud to announce its participation in the Advanced Design & Manufacturing Expo (ADM), taking place October 21 – October 23, 2025, at the Toronto Congress Centre.

Shop3D.ca Open House: 3D Scanning with the EinScan Rigil

September 22, 2025

Join the Shop3D.ca technical team for an interactive demo of the new EinScan Rigil 3D scanner. Learn the ins and outs of professional 3D scanning, and bring a medium-sized object to scan. You’ll leave with your very own 3D model file—just make sure your item is light enough to handle and can be rotated during scanning.

Shop3D.ca at the Canadian Manufacturing Technology Show (CMTS)

September 10, 2025

Shop3D.ca, Canada’s leading provider of 3D printing solutions, is proud to announce its participation in the Canadian Manufacturing Technology Show (CMTS), taking place September 29 – October 2, 2025, at the Toronto Congress Centre.