This product has been discontinued. Please refer to the Form Wash V2 (Form 4) - Automated Wash Cycler

While you’re away, parts are precisely agitated in IPA, getting every nook and cranny perfectly clean. Once washing completes, Form Wash automatically lifts parts out of the IPA, avoiding over-soaked, warped prints. Parts air dry and are ready when you are.

- Printer Compatibility: Form 3, Form 2

-

Dimensions: 26.2 x 29.3 x 34.0 cm

(10.3 x 11.5 x 13.4 in) - Height when open: 64 cm (25.2 in)

- Weight: 6.7 kg (14.5 lbs)

- Bucket Volume: 8.6 L of IPA to fill bucket

- Maximum Part Height: 18.5 cm (7.28 in)

- Suggested Operating Enviroment: 18-28 °C (64-82 °F)

- Maximum Cure Chamber: 80 °C (176 °F)

-

Power Requirements: 90–240 V

2.0 A

50/60Hz 50 W

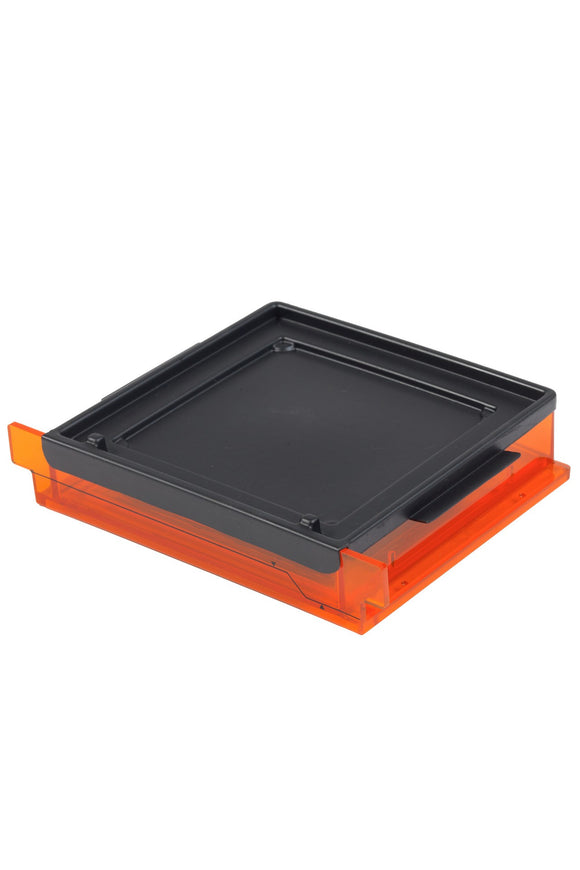

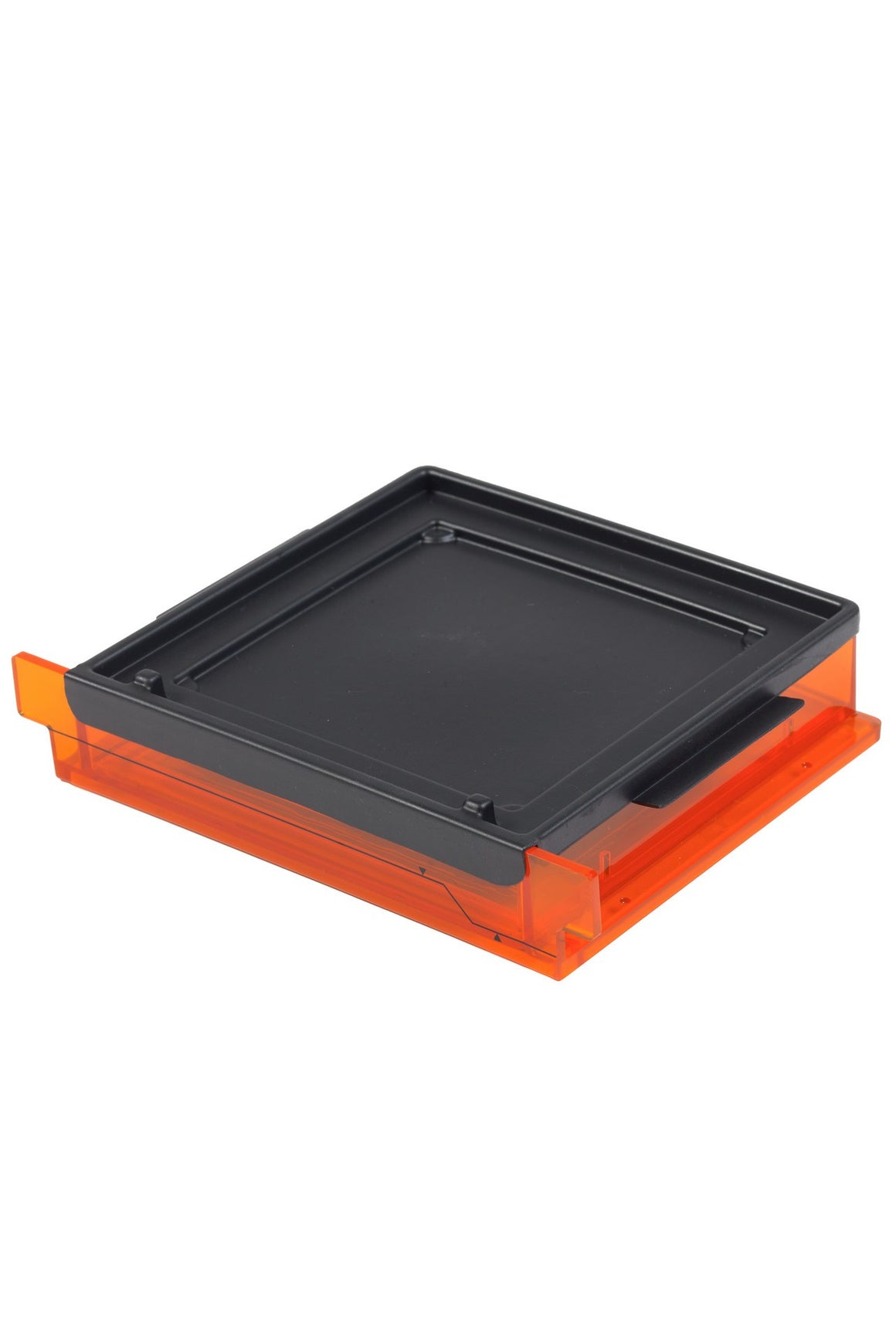

- Wash Bucket

- Wash Basket

- Hydrometer

- Siphon Pump

- Part Removal Tool

- Scraper

- Tweezers

- Flush Cutters

-

15 MINUTES

Approximate wash time when using fresh isopropyl alcohol (IPA) -

8.6 LITERS IPA

volume for removable wash bucket -

70 PRINTS

Amount of prints per IPA refill in regular use

Built to complete the stereolithography (SLA) engine, Form Wash and Form Cure streamline your 3D printing process to produce better results with less time and effort.

Automated Cleaning with Form Wash

- Isopropyl alcohol (IPA) washing system for stereolithography (SLA) prints after they come out of the printer

- Automates IPA washing, which can be the messiest part of SLA 3D printing

- Designed to work seamlessly with the Form 2 build platform

- Consistently Clean: Form Wash's rotating impeller agitates isopropyl alcohol (IPA) around every nook and cranny of your parts, getting them perfectly clean--every time.

- Built to Fit the Build Platform: Parts travel straight from the Form 2 to Form Wash; they can stay right on the build platform or be placed in the basket.

- Automated Wash Cycle: Manual washing requires careful attention, as parts left too long in IPA can become warped/deformed. Form Wash automatically raises parts out of IPA when wash time is up. Parts air dry and are ready when you are.

- IPA Calibration: Form Wash can hold up to 8.6 L liters of IPA, enough to wash approximately 70 prints. The hydrometer lets you know when it’s time to change out IPA. A siphon makes it easy to transfer IPA in and out of the wash bucket.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.