Raise3D Premium ASA Filament - 1.75mm (1kg)

Product SKU: [S]5.11.01052A01

$57.50

Loading...

ASA, which stands for acrylic styrene-acrylonitrile, is an amorphous, opaque thermoplastic that is structurally similar to ABS.

In many cases, they are quite interchangeable in purpose but ASA has a few key differentiating features that make it suitable for certain applications over ABS. ASA is significantly more resistant to UV light and weathering, making it the better choice for applications with extended outdoor exposure. ASA can boast slightly better mechanical properties but it can also cost slightly more in some cases.

Since ABS is so popular and has many more options, it is generally recommended to go with ABS unless outdoor exposure is a concern.

Related Items

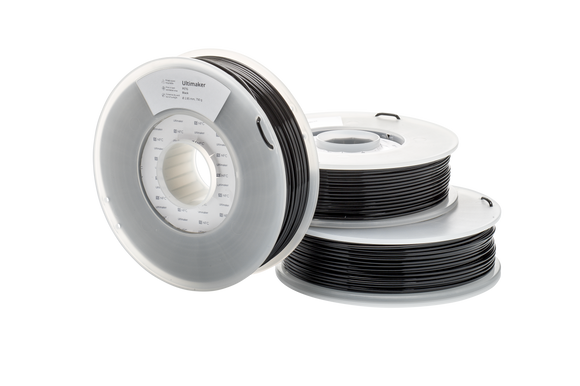

UltiMaker ABS Filament

$84.00

3D Printing with ABS does release harmful odours. ABS should not be used in a classroom environment without an enclosure and filtration. ABS printing should be conducted in a well-ventilated...

UltiMaker TPU 95A Filament (Flexible)

Sold Out $134.00

UltiMaker TPU 95A - Thermoplastic Polyurethane Highly versatile for industrial applications, TPU 95A (thermoplastic polyurethane) filament is the go-to choice for a wide array of manufacturing projects that demand the...

UltiMaker PETG Filament

$84.00

UltiMaker PETG Filament UltiMaker PETG sets the standard for industrial applications. Easy to use and versatile, it's suitable for a wide range of use cases from functional parts to visual...

eSun 3D Printing PETG - 1kg

$26.00

Due to the Covid-19 outbreak, our regular stock supply has been disrupted and possibly out of stock for a longer than expected period. We are still receiving regular shipments from...

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.