Tough 2000 V2 is newly announced, on Pre-order. ETA 1st shipment in Jan 2026.

This resin requires a Formlabs V2 Tank when using a Form 3.

- Reduced brittle failures: Increased elongation by more than 100%.

- Improved strength and stiffness: Increased flexural strength and flexural

modulus by roughly 15%. - Better performance at elevated temperatures: Increased heat deflection

temperature by roughly 25%. - Professional-looking parts: New dark-grey color.

- Strong and stiff prototypes

- Jigs and fixtures requiring minimal deflection

- Simulating the strength and stiffness of ABS

Tough 2000 is the stiffest material out of the Tough and Durable family. If you need a less stiff material, try Tough 1500 Resin or Durable Resin.

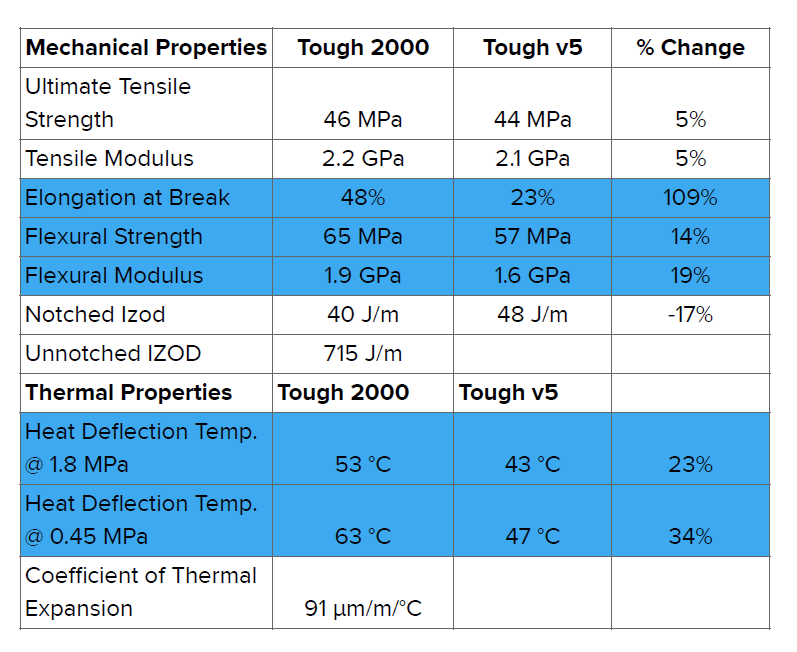

Strength, stiffness and elongation are typically opposing properties. Tough 2000 Resin now uses higher performing components such as those in Rigid Resin and Elastic Resin. This resulted in a complete reformulation and a brand new resin superior to Tough V5.

Below is a direct comparison of the mechanical properties between Tough 2000 and Tough V5:

Supports Print Resolutions: 100 and 50 microns

Curing Period: 60min at 70 degrees

Choose Tough 2000 Resin for prototyping strong and sturdy parts that should not bend easily.

Due to its high strength and modulus, Tough 2000 Resin can handle higher stress and will hold its shape better under load compared to Tough 1500 or Durable Resins. When pushed to its stress limit, Tough 2000 parts will bend significantly before ultimately breaking.

All Engineering resins requires UV post-cure when finishing for it to be fully cured, please consider the Form Cure to properly cure your functional resin prints.

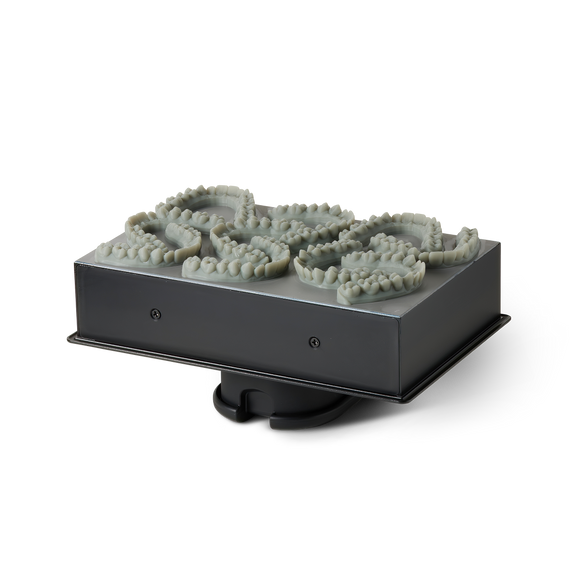

A side-by-side comparison of the Tough V5 resin and Tough 2000 resin.

Formlabs Engineering resins come in a resealable and refillable 1 Litre Cartridge.

Resins should be handled in accordance with Formlabs protocols.

A new resin tank should be used per Resin colour/type for your Form 2 / Form 3 printer.

Never mix the use of resin colours or types with a resin tank.

Purchase additional resin tanks here.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.