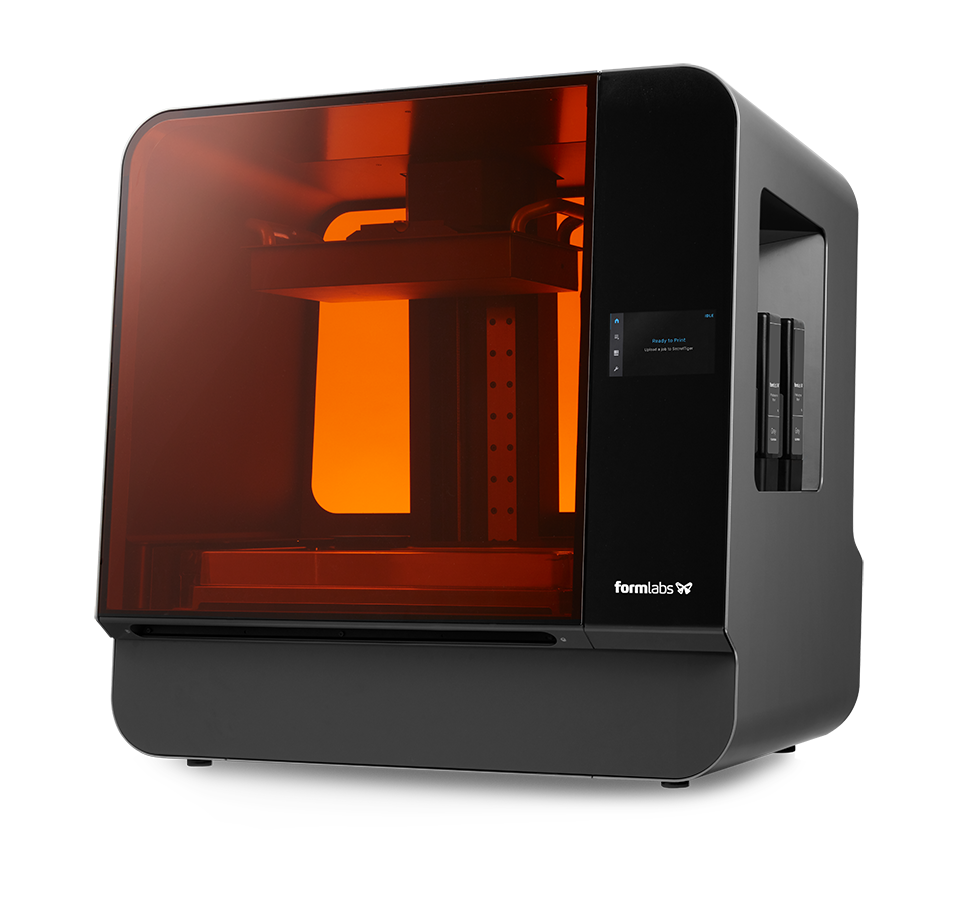

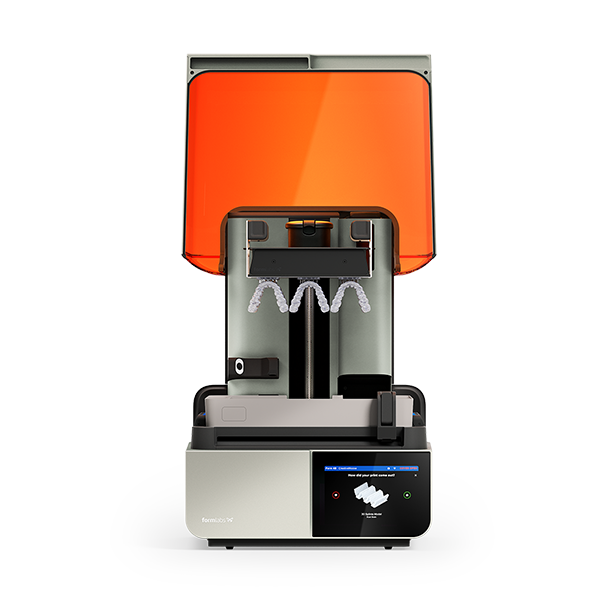

The next generation of large format 3D printing technology, specifically for Biocompatible materials. Designed for heavy use for daily large scale production.

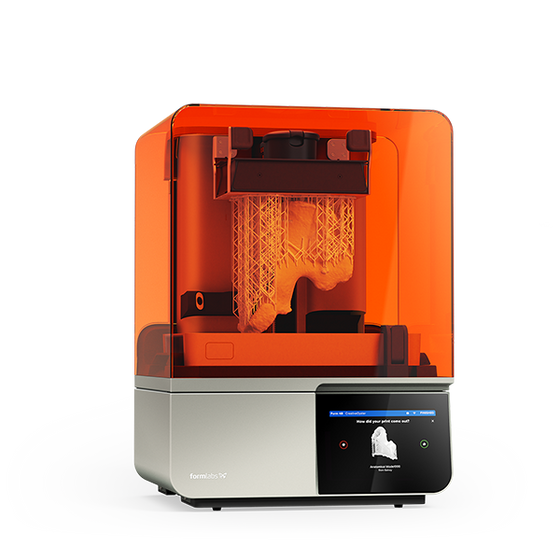

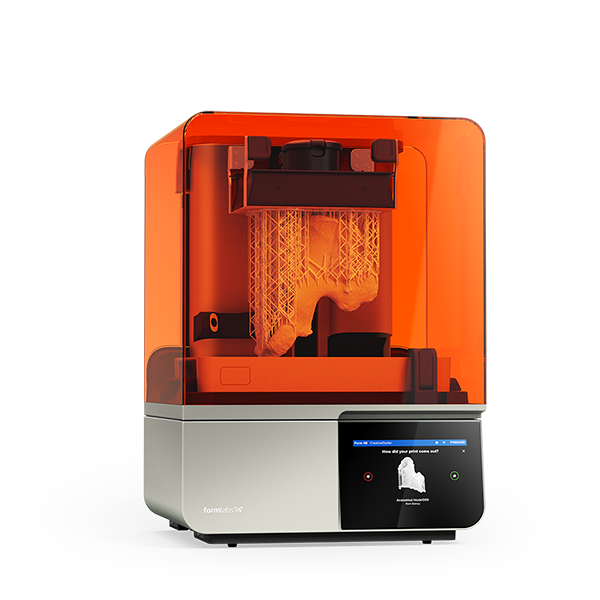

Print around the clock with a large-format 3D printer that’s compact enough for an office and robust enough for the factory floor. Whether you’re packing the build volume for batch production or printing bulky parts, the Form 3BL maintains ideal print conditions for nonstop throughput with minimal supervision. The Form 3BL continues to provide the incredible surface finish and fine detail that stereolithography 3D printing is known for.

Form 3BL - ROI Calculator

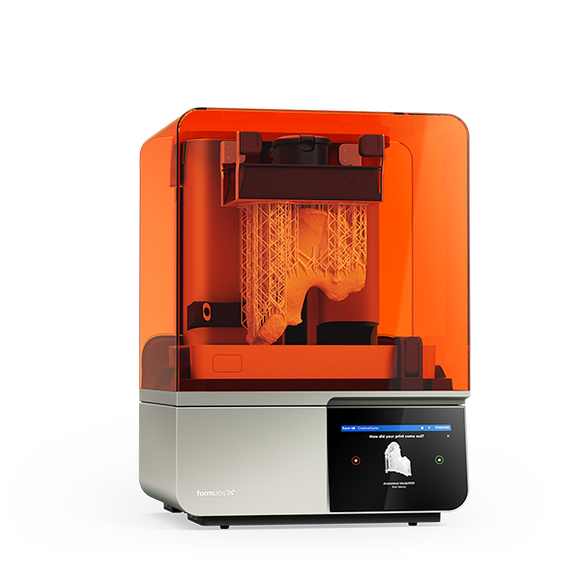

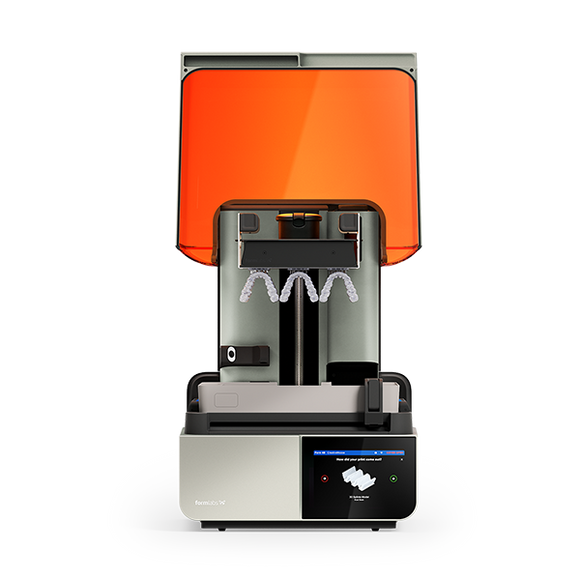

- Technology: Low Force Stereolithography (LFS)™

- XY Resolution: 25 microns

- Laser Spot Size: 85 microns

-

Laser Power: Two 250 mW lasers

-

Build Volume (W x D x H):

33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in) - Layer Thickness: 25 – 300 microns

- Usable with Biocompatible Formlabs Resins

- Form 3BL 3D Printer

- Form 3BL Build Platform

- Form 3BL Resin Tank

- Form 3 Finish Kit (Rinse Bucket and Cleaning Tools)

- 1 Year Professional Services Plan

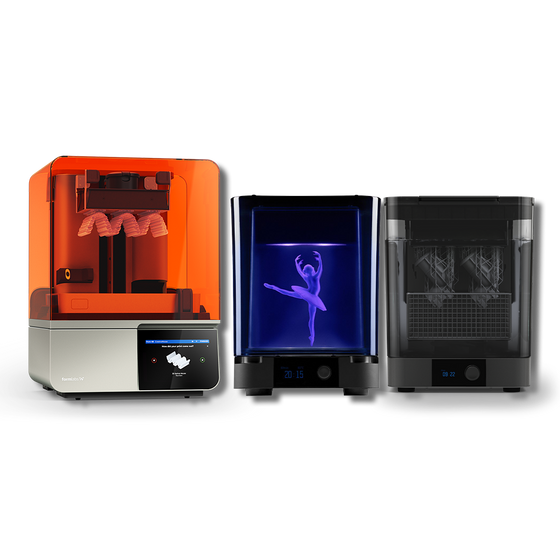

Optimized for Large Scale Printing

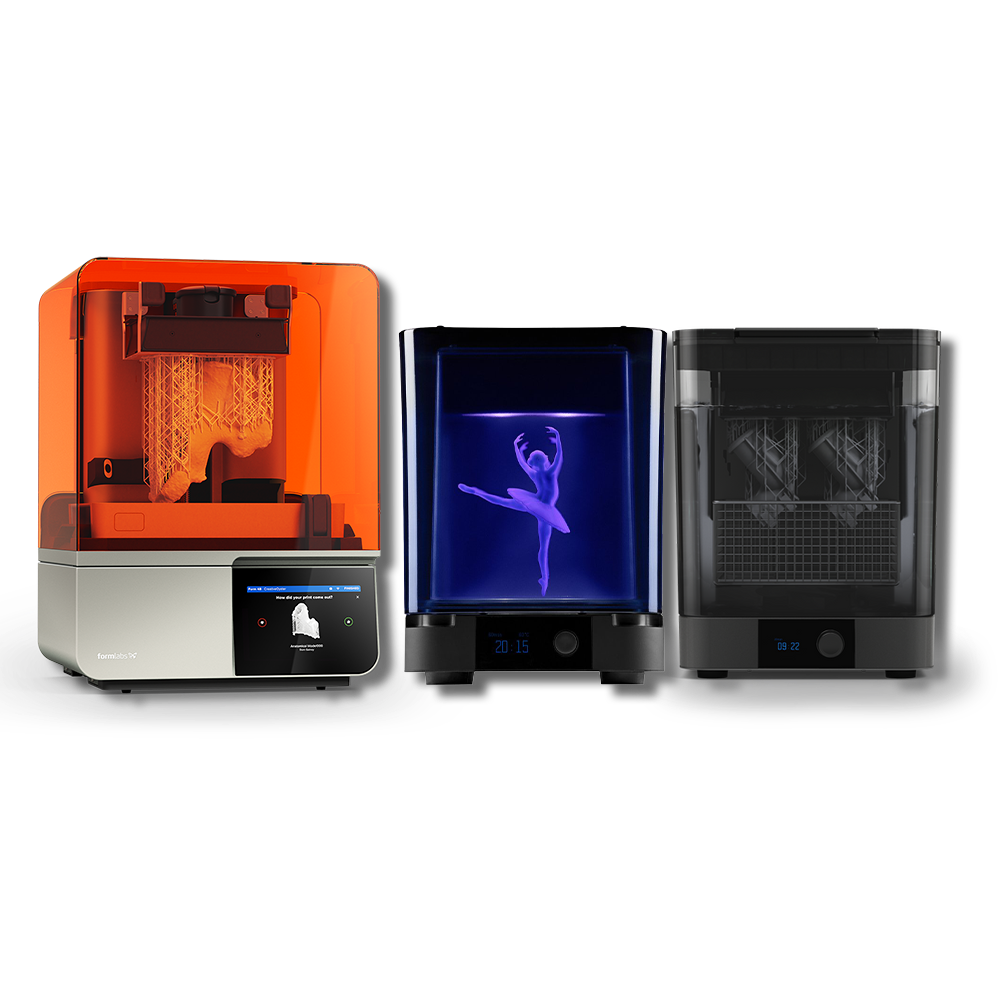

- The Form 3L has roughly 5x the build volume of the Form 3

-

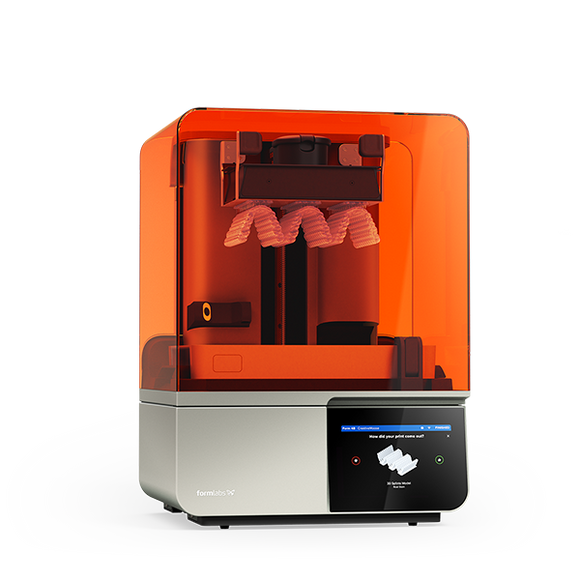

Two Parallel Light Processing Units (LPUs) and accepts two resin cartridges at the same time to feed large prints

- Accepts 2 resin cartridges at the same time to feed large prints

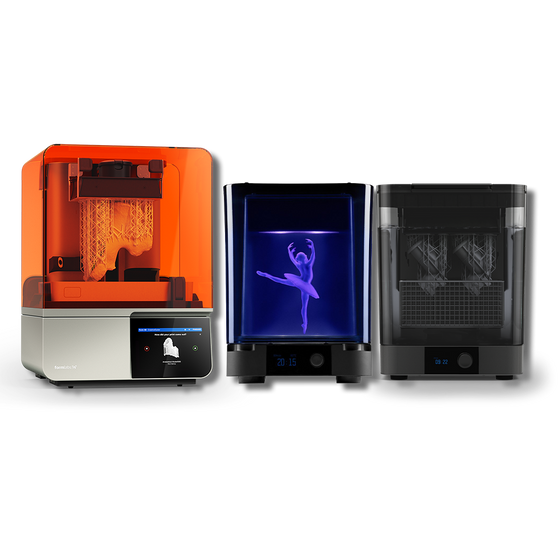

Flawless prints, every time.

- LFS (Low Force Stereolithography) 3D printing balances detail and speed.

- The optical system maintains a precise, dense laser spot to ensure accurate, repeatable prints.

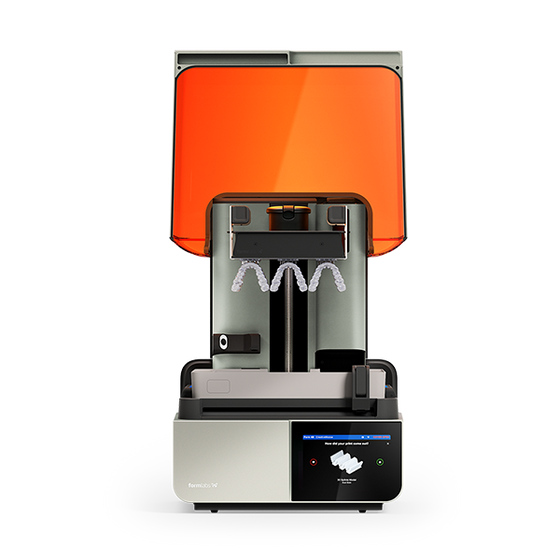

- Easy clean-up and smoother parts with tear-away light-touch supports.

Nonstop printing.

- Integrated sensors monitor and maintain ideal conditions for consistent performance over time.

- Switch between materials in seconds with a simple cartridge system.

- User-replaceable components and foolproof design maximize uptime.

Grows with your business.

- Meet demand, now and forever. Easily transition from one to many with systems that scale.

- Don’t wait. Print from anywhere as soon as you have files with Remote Print.

- Works well with teams. Monitor and manage prints and teams with PreForm and Dashboard. Track individual usage and adjust the print queue when you need to prioritize.

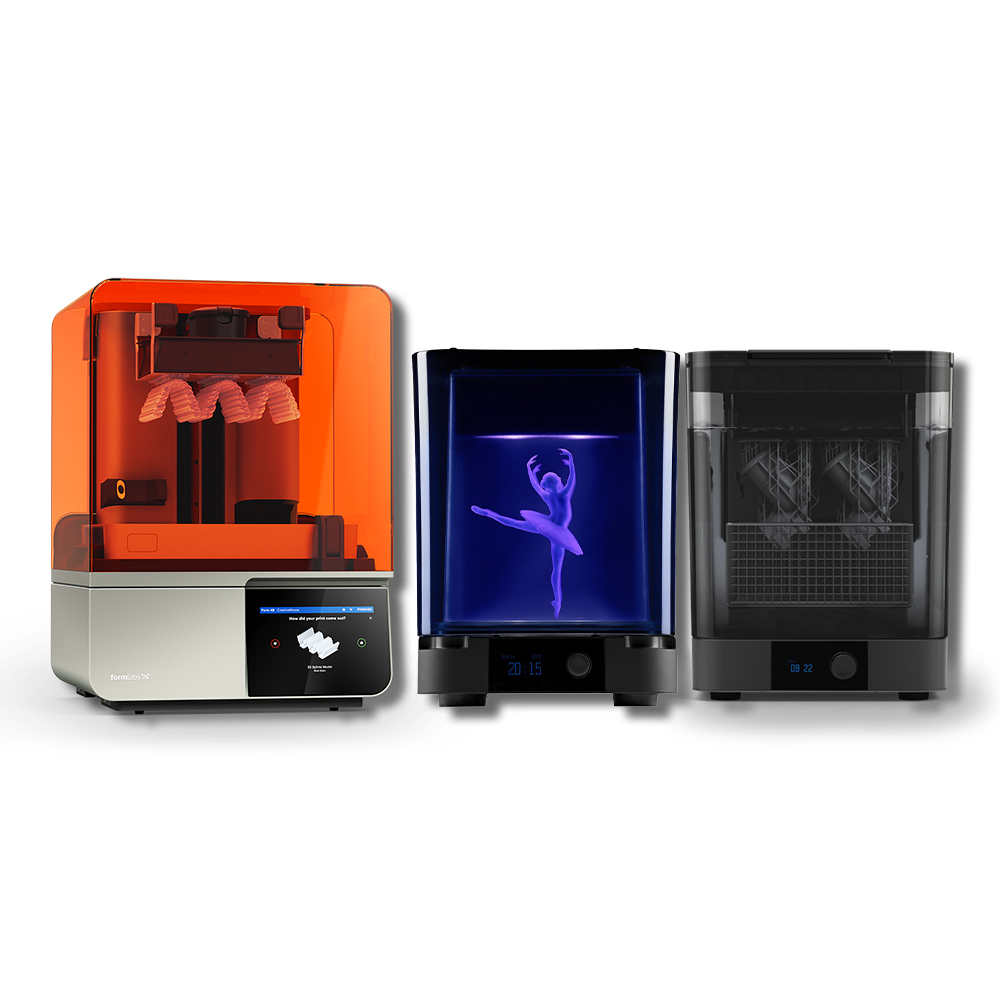

Main Features

User Replaceable Optical Module

Smart, redesigned optical module allows users to easily replace the core laser module. Reduce downtime, stock backup parts, and allow for future optical module upgrades.

Perpendicular Laser Motion Control x 2

The Form 3BL’s state of the art dual laser system now stays perfectly perpendicular with the build surface ensuring edge to edge consistency at any build volume. Increased spot and overall surface quality.

Low Force Peel

Completely redesigned Peel system reduces peel forces. This allows for more reliable printing of difficult parts, large layers and dramatically improves part quality.

Even Better Print Quality

The Form 3BL revolves around part quality, with many laser, peel and support improvements, part quality is more consistent and is even more crisp, beautiful and detailed than ever before.

Smaller Supports Required

Cleanup even easier now with the new low force peel technology. Because of lower forces on the part throughout the print, supports and touch points can be a lot smaller resulting in a much easier post-cleanup process. Less blemishes, less labor, less material used.

Longer Tray Life

Form 3BL's Resin tanks now last 20 times longer than standard Form 2 tanks so you can keep churning out parts without worry.

General SLA Features

Unparalleled Surface Quality

SLA printing produces the highest quality prints. With parts that come off the machine looking like they’re injection molded. Layer lines are minimal, details incredible. From detailed jewelry casting masters to dental crowns, the Form 3 Line is unmatched in part quality, detail and cleanliness.

Reliable

With a high success rate (90%+) You don’t need to worry about failed prints the next day. Run the machine 24/7 on production or prototyping tasks. All can be done on one machine without reconfiguring or calibrating.

Ease of Use

Resins are thoroughly tested by Formlabs and all settings are pre-set and optimized so you don’t need to tweak any settings. Simply choose your resin, resolution, and print. Everything else is taken care of behind the scenes.

Future Proof

With drop-in modules and constantly evolving library of resins, the Form 3BL is the platform in which the future 3D printing will happen. From niche and industry-specific resin like Castable and High temp to experimental resins like Ceramic and Colors, you can be sure there will be a steady stream of new developments on the horizon.

Resin Compatibility

Make use of Formlabs’ already impressive resin library from day 1. Over 15 general and niche application resins. From dental, high temperature to castable resins, all with one system.

Certified

The Form 3BL is CSA Compliant and comes with a cUL marking

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.