The UltiMaker Metal Expansion Kit is designed for use with UltiMaker S5 printers

Use of the Air Manager is strongly recommended when printing with BASF Forward AM Ultrafuse® 17-4 PH material

Comes with a DHS sintering coupon

Very Important - Special Considerations for this filament is considered an expert user level filament. Successfully printing, debinding and sintering requires very specific workflows that must be followed without exception. Any deviation can damage your printer, your finished print or the debinding equipment from our sintering partner. Exceptional care must be taken into account during printing and transport of green parts. Not all print geometries may be successful in the sintering process. Pre-planning and post-processing will increase the chances of success. We highly encourage booking a free appointment with our application engineers to discuss your application. Please be sure to reference all print guidelines from BASF prior to the consultation. No returns are accepted for opened filament or print or sintered failures.

UltiMaker Metal Expansion Kit - Complex Stainless Steel Parts Made Simpler

Take advantage of a new range of metal 3D printing applications by upgrading the UltiMaker S5 with the Metal Expansion Kit. Its seamless workflow makes creating stainless steel parts easier, more efficient, and affordable..

Print with BASF Forward AM Ultrafuse® 17-4 PH stainless steel filament1 to create a “green part”

Send your green part for post-processing by BASF’s network of certified debinding and sintering services

Track debinding and sintering progress via an online portal, and receive your part back in 10 business days

Put your finished metal part to use – from small series of tools to auxiliary components

- BASF Forward AM Ultrafuse® 17-4 PH (1 kg)

- Packaging for green parts

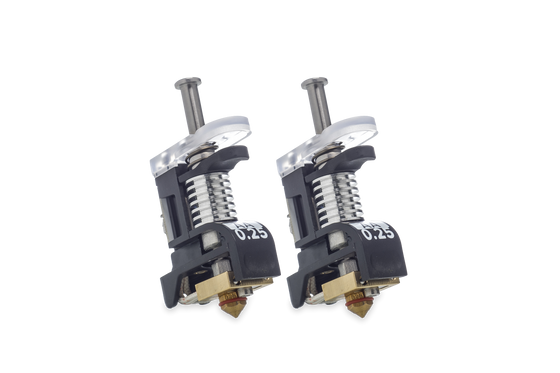

- UltiMaker Print Core CC 0.4

- Magigoo Pro Metal (50 ml) adhesive

- Free UltiMaker Cura software with optimized metal part slicing features

- Access to exclusive metal FFF e-learning content on UltiMaker Academy

- Build plate soaking station

- Voucher for post-processing (DSH) - Sent digitally to email for order separately

The UltiMaker Metal Expansion Kit provides access to software optimizations, post-processing services, and extensive e-learning modules.

The UltiMaker S5's low total cost of ownership and small size makes it easy to adopt and scale an affordable metal 3D printing solution. Compared to CNC and other additive methods, you can save up to 90% creating the metal tools and parts you need.

To 3D print metal on the UltiMaker S5, simply swap out the print cores, load the NFC-equipped metal filament, and start your print.

Being able to 3D print either plastic or metal on the UltiMaker S5 opens up a wider range of potential applications. And because you can quickly and easily switch between materials by changing out the print cores, your printer becomes even more versatile.

BASF Forward AM Ultrafuse® 17-4 PH

BASF Forward AM Ultrafuse® 17-4 PH is an ideal stainless steel for high-strength and stiff parts. It is also capable of withstanding the harshest operating conditions thanks to its excellent corrosion and heat resistance. These properties are achieved through a proven catalytic debinding and sintering process used for traditional metal injection molding.

Post Processing

Each UltiMaker Metal Expansion Kit includes a voucher toward post-processing your 3D print into a full metal part within 10 business days. This is possible via BASF's network of certified debinding and sintering services. Via an online portal, you can book your part's post-processing on the calendar and check in on your part's progress at any time.

Software

The UltiMaker Metal Expansion Kit unlocks extra features inside the UltiMaker Cura 5 engine. These make metal print preparation simpler – automatically and accurately compensating for shrinkage that happens during sintering across all axes. You gain better control over your part and increased metal print success.

E-learning

New to metal 3D printing? The UltiMaker Metal Expansion Kit gives every user access to an exclusive, 1-hour e-learning course. Get step-by-step guidance through the full workflow. And learn to successfully create high-quality metal parts with an UltiMaker printer.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.