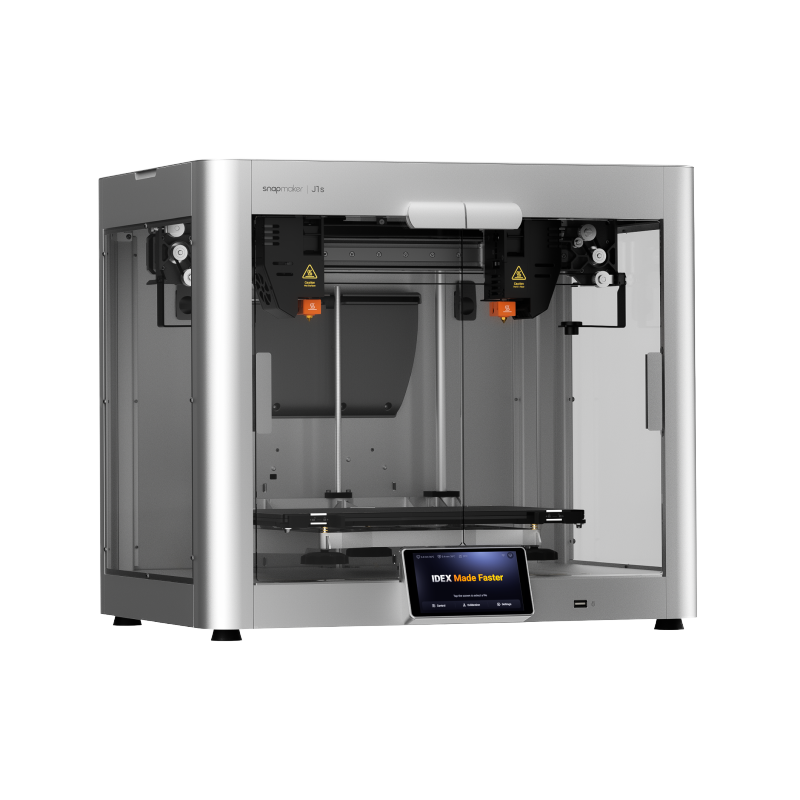

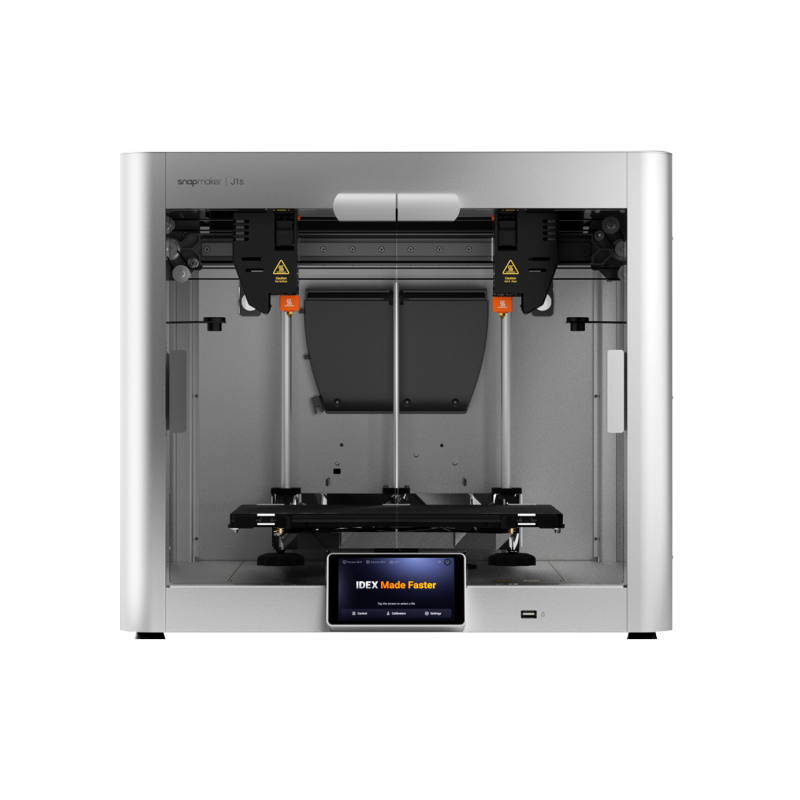

Snapmaker J1s 3D Printer features lightning-fast independent dual extruder (IDEX) and incredible flexibility in material selection, with four printing modes and the industrial-grade linear rails which delivers high print quality. Packed with user-centric designs, J1s makes 3D printing a simple fun.

- Up to 10,000 mm/s² acceleration and up to 350 mm/s printing speed

- Breakaway supports and dissolvable supports for effortless removal

- Copy Mode and Mirror Mode that double productivity

- 300°C hot ends & 100°C heated bed

- Print volume 300 × 200 × 200 mm³

- Easy-swap hot ends with multi-diameters

- Double-sided PEI Glass Plate

- Built-in nozzle wipers

- Technology: Fused Filament Fabrication (FFF)

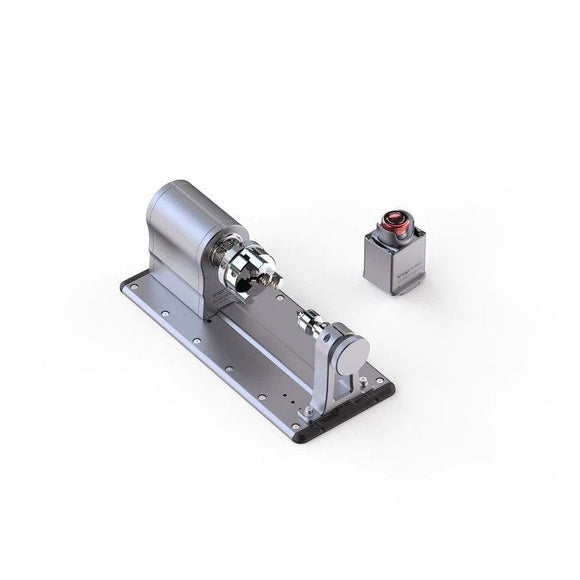

- Extruder System: Independent Dual Extruders (IDEX)

- Printing Modes: Default, Backup, Copy & Mirror

- Build Volume: Default/Backup (300mm x 200mm x 200mm), Copy (160mm x 200mm x 200mm), Mirror (150mm x 200mm x 200mm)

- Layer Height (with 0.4mm nozzle): 0.05 mm–0.3 mm

- Build Plate: PEI glass plate

- Max Heated Bed Temperature: 100°C

- Nozzle Diameter: 0.4 mm (included) 0.2 mm, 0.6 mm, 0.8 mm, Hardened (sold separately)

- Max Nozzle Temperature: 300°C

- Filament Diameter: 1.75 mm

- Supported Materials: PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, PA, PA-GF, PA-CF

- Data Transmission Methods: Wi-Fi, USB cable, USB flash drive

- Operating Noise: < 50 dBA

- Dimensions (W × D × H): 539 mm × 401 mm × 464 mm

- Net Weight: 25 kg

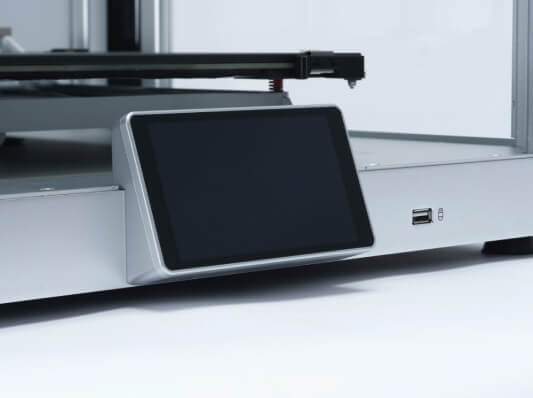

- Touchscreen: Size: 5 in., OS: Android, Resolution: 1280 × 720 pixels

- Memory: 1 GB RAM, 8 GB eMMC

- Repeatability of Linear Rails: ± 0.03 mm (X/Y), ± 0.02 mm (Z)

- Expected Lifespan of Linear Rails: Over 10 Years

- Operating Environment: Temperature: 10ºC–35ºC, Relative Humidity: 10%–90% (non-condensing)

- Storage Environment: Temperature: -20ºC–55ºC, Relative Humidity: 10%–90% (non-condensing)

- Power Input: Rated Voltage: AC 100 V–240 V, 50 Hz/60 Hz, Rated Current: 4.4 A Max.

- Power Output: DC 24 V, 400 W Max.

- Supplied Software: Luban (third-party software supported)

- Supported OS of Luban: Windows, macOS

- Supported File Formats: STL, OBJ, 3MF

- Output File Formats: Gcode

- Snapmaker J1s 3D Printer

- Quick Start Guide

- Safety Guidelines

- Calibration Card

- Wiping Cloth

- PLA Filament x2 (Orange, White)

- Left Door

- Right Door

- Side Panel x2

- PEI Glass Plate

- USB Flash Drive

- Tweezers

- Power Cable

- Palette Knife

- Wire Brush

- Diagonal Pliers

- Filament Holder

- USB-B Cable

- M3 x 6 Screw (x16)

- M4 x 8 Screw (x4)

- Hot End Sock (x2)

- 5.5mm Wrench

- Hex Keys (H3.0, H2.5, H2.0, H1.5)

Fast & Forward.

Max. Speed: 350 mm/s

Max Acceleration: 10,000 mm/s2

Speed Boosted by Advanced Control Algorithm.

Vibration Compensation

J1s brings you a top-of-class printing speed of 350 mm/s while ensuring a high resolution of prints. It is made possible by the optimization of the vibration compensation technology. This technology reduces the vibrations caused by high-speed movements, minimizing ringing to enhance print quality. With the maximum acceleration of 10,000 mm/s², you can realize small models packed with details with efficiency.

Seamless Extruders Switching

During dual extrusion printing, the non-working extruder preheats while on standby, and starts printing right after the working extruder leaves, significantly reducing your waiting time.

Cornering Optimization

By analyzing the extruders' moving directions ahead of time, J1s is able to prevent problems like corner bulge, delivering better print quality at corners.

IDEXcel in Dual-material Printing.Compared with a multi-material unit, IDEX dual-material printing requires less time in filament changing and creates less waste. Plus, IDEX offers the cleanest two-extruder solution that prevents cross-contamination. It creates a clean interface between two materials, embracing hassle-free removal and avoiding stains and weird blending along the seam.

Snap Removal, Smooth Finishes.Building and removing support can look like rocket science sometimes, but we've done the math for you–steady support, clean interface, effortless removal, and minimal post-processing needed to maintain high dimensional accuracy. See your model as it is, no less, no more.

Breakaway SupportBreakaway filament offers the same support as normal materials but is much easier to remove without the need for further post-processing.

Dissolvable SupportJ1s supports PVA and other dissolvable materials. Soak the print, and the supports dissolve, leading to a smooth surface and excellent dimensional accuracy. When you are looking for complex geometry, hollow structures, and exquisite details, this is for you.

Print in ParallelHalve your wait time, double your productivity. IDEX is the only extrusion system with two separate extruders moving independently on the X-axis, enabling you to run two prints simultaneously.

Copy ModePrint two identical objects in one go. It is especially suitable for batch printing, empowering studios and enthusiasts. If one of the prints runs into an issue, you can stop that print without affecting the other. This mode is a lifesaver for a promised delivery on a tight schedule.

Mirror ModeJ1s directly mirrors your model and prints the original and the mirrored one in one go. For a symmetrical model, you can import half of it and print it in Mirror Mode to cut your wait time by 50%, perfect for quick drafts and concept models. Like in the Copy Mode, you can stop one print without affecting the other.

Backup ModeUnder Backup Mode, you print with one extruder while the other stands by. If the working extruder bumps into a hiccup, the stand-by one would take over the job seamlessly and still deliver a fabulous print to you.

3, 2, 1, Calibration Done.We utilize electrical conduction to locate the two hot ends and the heated bed and measure the distances between the three entities—a creative solution to complex IDEX calibration. This time saver enables you to complete the calibration in 10 minutes under the Assist Mode.Taking away the calibration card and the judgement call, it reduces errors and arrives at better accuracy.

Hands-free XY Offset Calibration.When the two hot ends touch the square opening on the heated bed, it sends out electronic signals to suggest their exact locations, and J1s calculates the offsets between them. J1s then auto-compensates the offsets during printing to ensure perfect XY alignment that avoids layer shifting and improves the success rate of dual-material prints. It takes away the long learning curve and saves you from scrutinizing through an awful lot of lines. Tap start, and lay back for elevated precision.

Tool-free Bed Leveling.A level print bed lays the foundation for successful 3D prints, but the bed leveling of IDEX printers can be very time-consuming. Using a PEI glass plate of high flatness, J1s can downsize from a 3 × 3 (9 points) or 4 × 4 (16 points) leveling to a 3-point one with no compromise on levelness and downtime dropped by 70–80%. Turn the leveling wheel as guided on the touchscreen, and the bed is leveled for tip-top first-layer adhesion.

Easily-managed Z Offset Calibration.Using electrical conduction, J1s can calculate the distances between the hot ends and the heated bed. Thus, we were able to cut the step of moving the calibration card back and forth while adjusting the Z offset. Simply turn the thumb wheel as guided on the touchscreen and you are now the Z offset calibration guru!

Custom PEI Glass Plate.J1s's build plate is made of glass with sheer flatness, making your first layer smooth and adhesive. Glossy glass on one side and PEI coating on the other side, aiding in adhesion for various filaments. The plate can be easily removed so that it is extra handy for maintenance and print removal.

Easy-swap Hot Ends.Loosen the two screws on the hot end, fix or replace the hot end, and go back to printing at once. For the adventurers going for more variations and advanced applications, we offer multi-diameter hot ends from 0.2 mm for detail accuracy to 0.8 mm for faster printing, and hardened hot ends for engineering materials.

Built-in Nozzle WipersScrape excessive materials off nozzles and halt the oozing from the just-active extruder to free multi-material prints from blobs and stringing. The extruder can start its print job in line without waiting for the just-active one to cool down. Switching between extruders takes much less time, once again minimizing downtime.

Pre-assembled & Tuned. Ready When You Are.Tuned and tested to its best condition. When J1s arrives at your doorstep, just unbox, mount the filament holders, doors and panels, and start right off.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.