Inside Boston University’s Engineering Product Innovation Center

October 17, 2018

Boston university's Engineering Product Innovation Center (epic) was designed to provide access to state-of-the-art design, prototyping, and small-scale manufacturing technologies to all members of the school’s community. This allows engineering students access to new ways they can explore innovation, the entrepreneurial process, product design and manufacturing.

“In the broadest sense, our mission is to prepare students with the skills they need to excel in for careers in design, manufacturing, and engineering,” said Dr. Gerry Fine, professor of practice and director of EPIC.

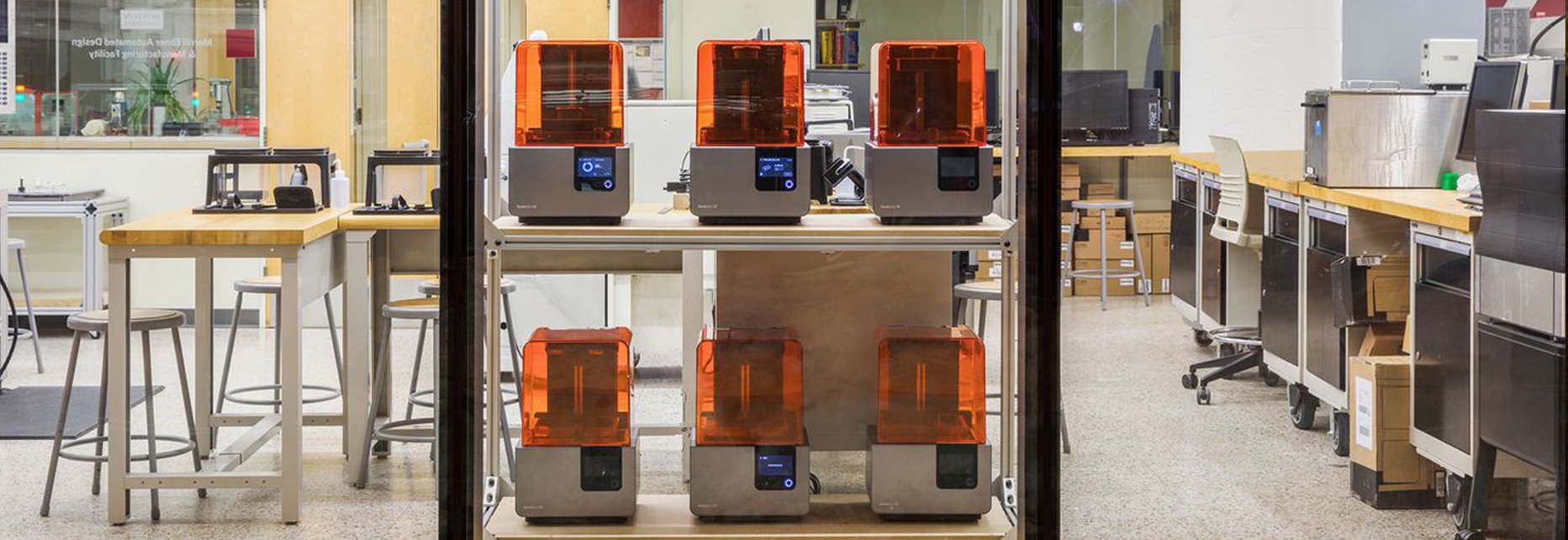

Serving 1000 students per semester, EPIC offers a full range of technologies to help their students learn product development and manufacturing from start to finish. Their list of tools included CAD, CNC machines and automated robotic manufacturing. In 2016 they introduced Stereolithography (SLA) 3D printing with the addition of the Formlabs Form 2. They then expanded to six Form 2 printers due to the demand. Students are producing 400 prints per month while the printers run for 16 hours a day!

For Dr. Fine, equipment dependability is a top priority. “The Form 2 offers the kind of reproducibility and reliability we were hoping for, and has been much more fruitful than working with other technologies,” Dr. Fine said.

Also in News

2025 HOLIDAY HOURS

December 05, 2025

As we gear up for the holidays, our schedule will look a little different. Please take note of our adjusted hours!

Holiday Shipping Notice 2025

December 05, 2025

With the holidays fast approaching, shipping volumes for Canada Post and all other couriers are expected to be higher than usual.

If you’ve been eyeing a 3D printer or accessory to gift that special person, or you’re looking to pamper yourself with a 3D printing gift this season, delay no further! We encourage you to plan ahead to give extra time to allow for the arrival of your order.

If you’d like your order to arrive before Christmas, make sure to order by December 12th.

Shop3D.ca at ADM Toronto (Advanced Design & Manufacturing Expo)

September 23, 2025

Shop3D.ca, Canada’s leading provider of 3D printing solutions, is proud to announce its participation in the Advanced Design & Manufacturing Expo (ADM), taking place October 21 – October 23, 2025, at the Toronto Congress Centre.