Powerful, reliable, versatile 3D printing

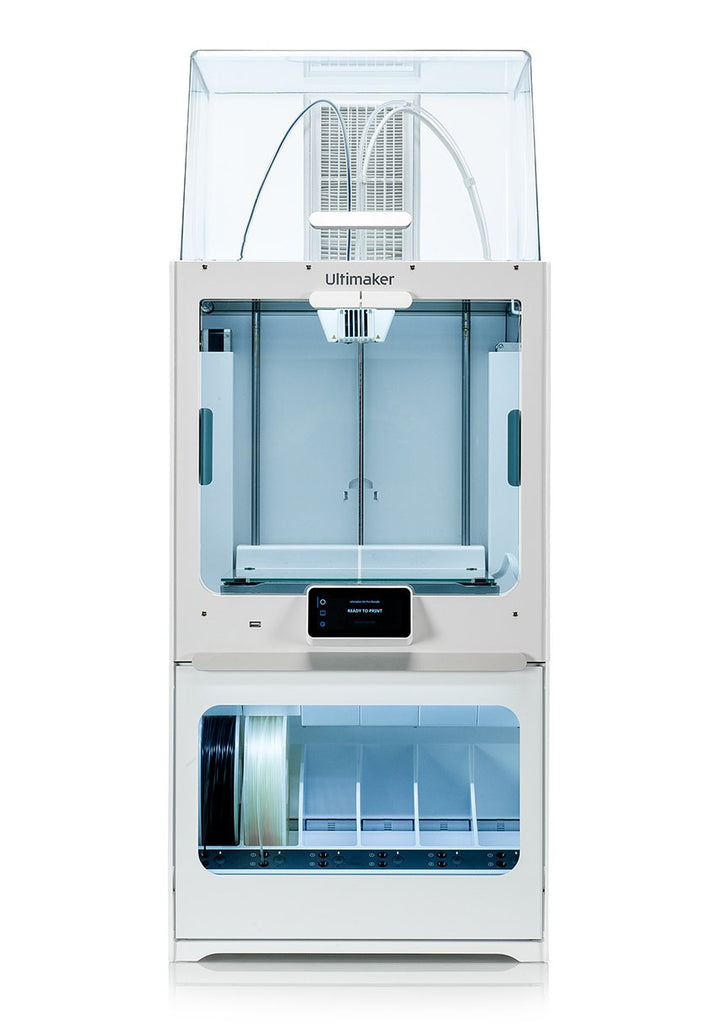

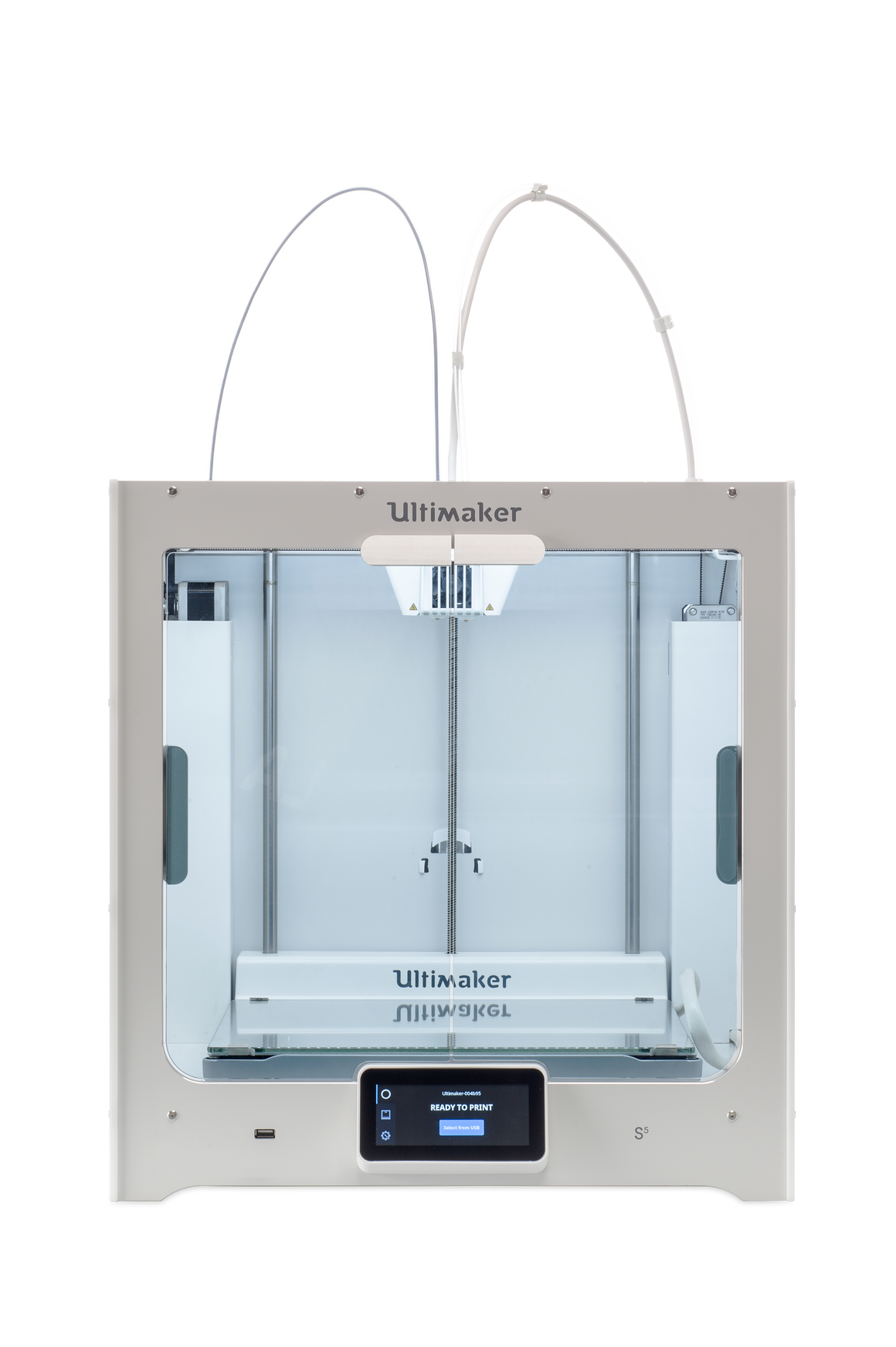

The UltiMaker S5 Studio is UltiMaker's most advanced 3D printer yet.

Professionals all over the world discovered that the UltiMaker 3 is a powerful, cost-effective solution to streamline their design and prototyping processes and take on more control. Building on the capabilities of the UltiMaker 3 and the feedback of the community, the UltiMaker S5 Studio adds enhanced performance with a larger build volume, improved ease of use, and unrivaled reliability.

All UltiMaker 3D Printers have cMETus Certification cleared marked on the bottom or the back of each unit. This mark is accepted by all electrical regulatory authorities in Canada.

- Large Build Volume of 330 x 240 x 300 mm (13 x 9.4 x 11.8")

- Layer resolution down to 20 micron

- Print temperature up to 280 °C

- Glass doors to control airflow

- Dual extrusion with a soluble support material

- Swappable print cores

- Heated build plate with active leveling

- Touch display

- UltiMaker S5 Studio 3D Printer

- UltiMaker S5 Air Manager

- UltiMaker S5 Material Station

- 3 Print Cores Included

- 1 Glass Bed

- 750gr. Spool of Tough PLA and 750gr Spool of PVA Dissolvable Support

- USB key, glue stick, grease, hex wrenches, cables

- Cura, our award-winning print preparation software

- Powerful UltiMaker app

- A calibration card to level the build plate

- Comprehensive 12 month warranty

- Lifetime expert support from Shop3D.ca

Air Manager

Reliability at scaleThe UltiMaker S5 Air Manager ensures a safer working environment, providing a closed, inside-out airflow for the UltiMaker S5 3D printer. It filters up to 95% of all ultrafine particles (UFPs) emitted during 3D printing and forms a safe, physical barrier to the print area.

More Materials, Less HassleOptimized software profiles precisely control filtering for every UltiMaker material and over 40 third-party filaments. So you can focus on creating the perfect 3D printed part with any material you choose. No worries about UFPs, and no extra time configuring your printer.

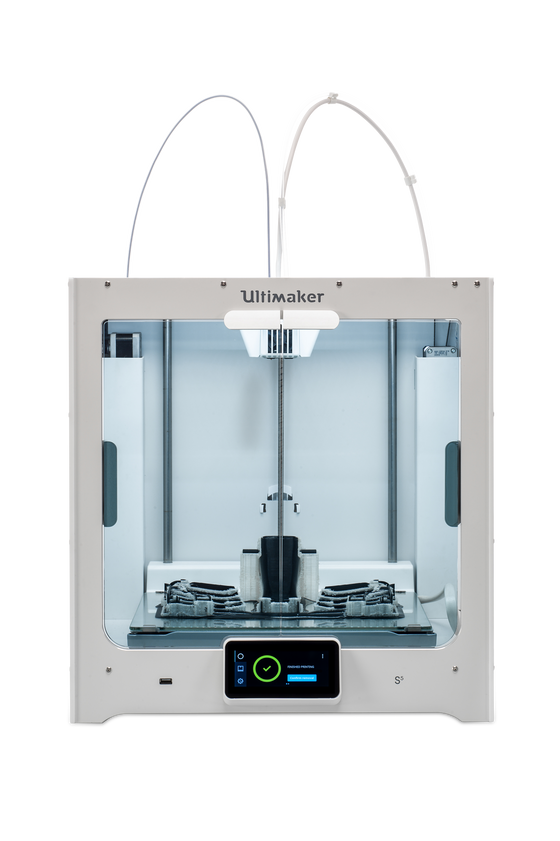

UltiMaker S5

Enhanced reliabilityTrust the UltiMaker S5 to do its job while you do yours. Its advanced active bed leveling ensures a perfect first layer, glass doors control the airflow, and dual fi lament flow sensors will pause your print and notify you if you run out of material.

Open And Connected SystemWith the UltiMaker S5, you are not only getting a market-leading 3D printer – you gain access to the UltiMaker platform. Access all the tools you need to start 3D printing – increased security, workflow management, and knowledge. UltiMaker brings it to your door, with features including a limited Digital Library for easy part storage and sharing, an IT knowledge base, and e-learning courses.

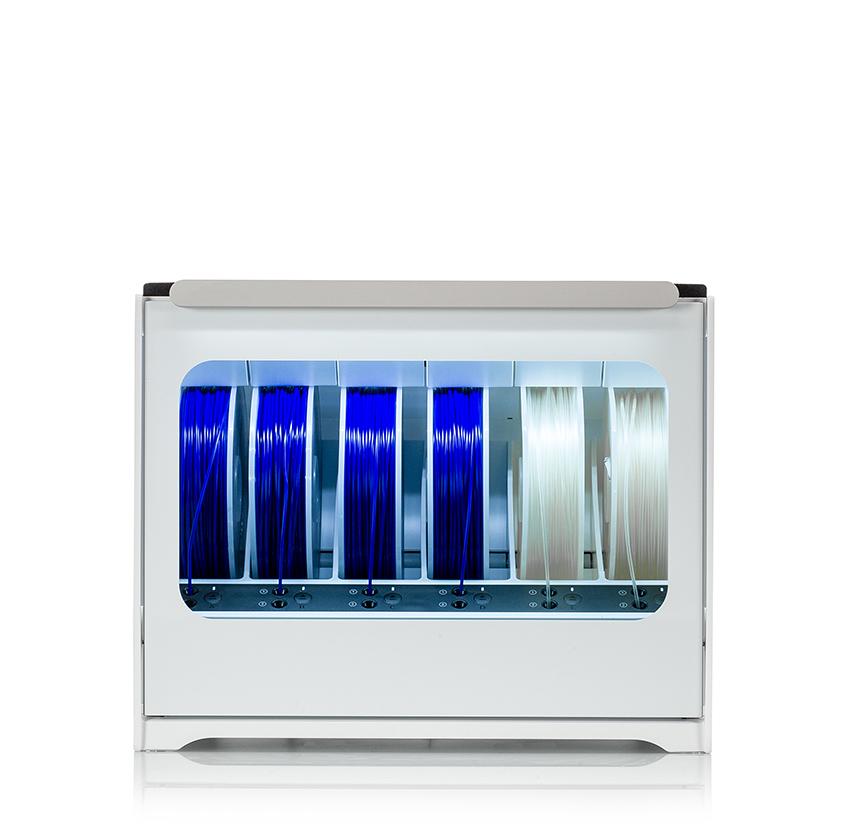

UltiMaker S5 Material Station

Productivity To Power Your BusinessSeamlessly integrating with the UltiMaker S5, the Material Station redefines material handling – to unlock truly 24/7 production. Load up to six material spools inside the humidity controlled chamber and smart features take care of the rest – composite-ready feeder wheels, filament flow sensors, and automatic switching when a material runs out. Now you can achieve increased productivity and higher-quality production.

Simplify Your 3D Printing WorkflowWe’ve been making 3D printing easier since 2011 – and this is our biggest step yet. Front-load materials in seconds, configure to your needs and stop worrying about material storage conditions. The UltiMaker S5 Material Station is also fully integrated into our software tools, so you stay informed and 100% focused on doing your best work.

Upgrade to a powerful suite of online software tools that help you to do more with an UltiMaker 3D printer. Stay in control. Gain more flexibility. Streamline your production. with unending access to security-assessed software – with remote printing, user management, and e-learning

UltiMaker Cura

Trusted by millions of users, UltiMaker Cura is the world’s most popular 3D printing software. Prepare prints with a few clicks, integrate with CAD software for an easier workflow, or dive into custom settings for in-depth control.

UltiMaker print cores make it quick and easy for you to change nozzle configurations on your 3D printer – giving you the flexibility to seamlessly print applications that are optimized for the job. Whether you're seeking fine details, a quick draft, or a nozzle specially developed for your chosen material type, our print cores have you covered.

Dual Extrusion

Achieve complex geometries and intricate designs with the UltiMaker S5’s reliable dual extrusion technology and water-soluble support. Print in a range of engineering and support materials for complete design freedom, with minimal post-processing.

Do I need to buy the whole Pro System at once?

No, each part of the pro system can be bought individually. You can find the UltiMaker S5 here, the air manager here and the material station here

What size filament do I need to use with the UltiMaker S5?

The UltiMaker family of printers all take 2.85MM Filament, it can be 3rd Party Filament or UltiMakers own OEM filament.

Where to find my printer serial number?

All UltiMaker printers have a serial number. The serial number sticker is located at the back of the machine, where the power cable is plugged into the unit. UltiMaker serial numbers begin with 'BPP-' and contain two sets of 6 digits.

Why Choose UltiMaker FFF?

3D Printers that simply work

Our award-winning 3D printers are robust, reliable, and easy to use. They deliver quality parts time and again. Designed and tested to run 24/7, they allow you to achieve the results you need more quickly and easily

Software ready for Industry 4.0

Trusted by millions of users across 14 languages, UltiMaker Cura integrates with any workflow through UltiMaker Marketplace plugins.Then scale production and digital distribution with UltiMaker Digital Factory.

Material Choice Like Never Before

UltiMaker offers the widest material choice on the market. Through our Material Alliance, choose the perfect filament for your application – from advanced polymers to carbon fiber composites.

Support dedicated to your success

Wherever you are in the world, UltiMaker support is close by. Our global network of service partners offer professional installation, training, and maintenance in your language and time zone.

Certifications

All UltiMaker 3D Printers have cMETus Certification cleared marked on the bottom or the back of each unit. This mark is accepted by all electrical regulatory authorities in Canada.

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.