Shipping Notes:

If stock is not listed in a Shop3D location, it will be shipped directly from a Canadian distributor warehouse with a longer lead time. Any concerns, please contact our sales team.

UltiMaker Factor 4

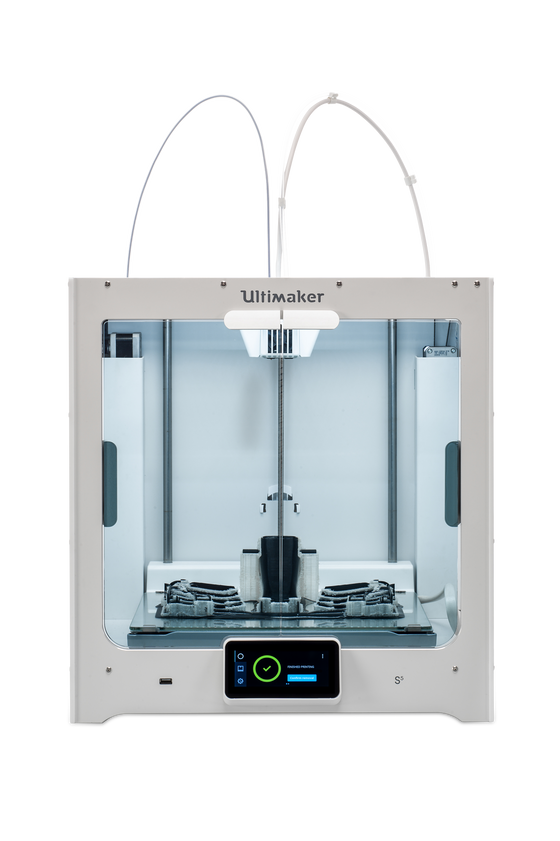

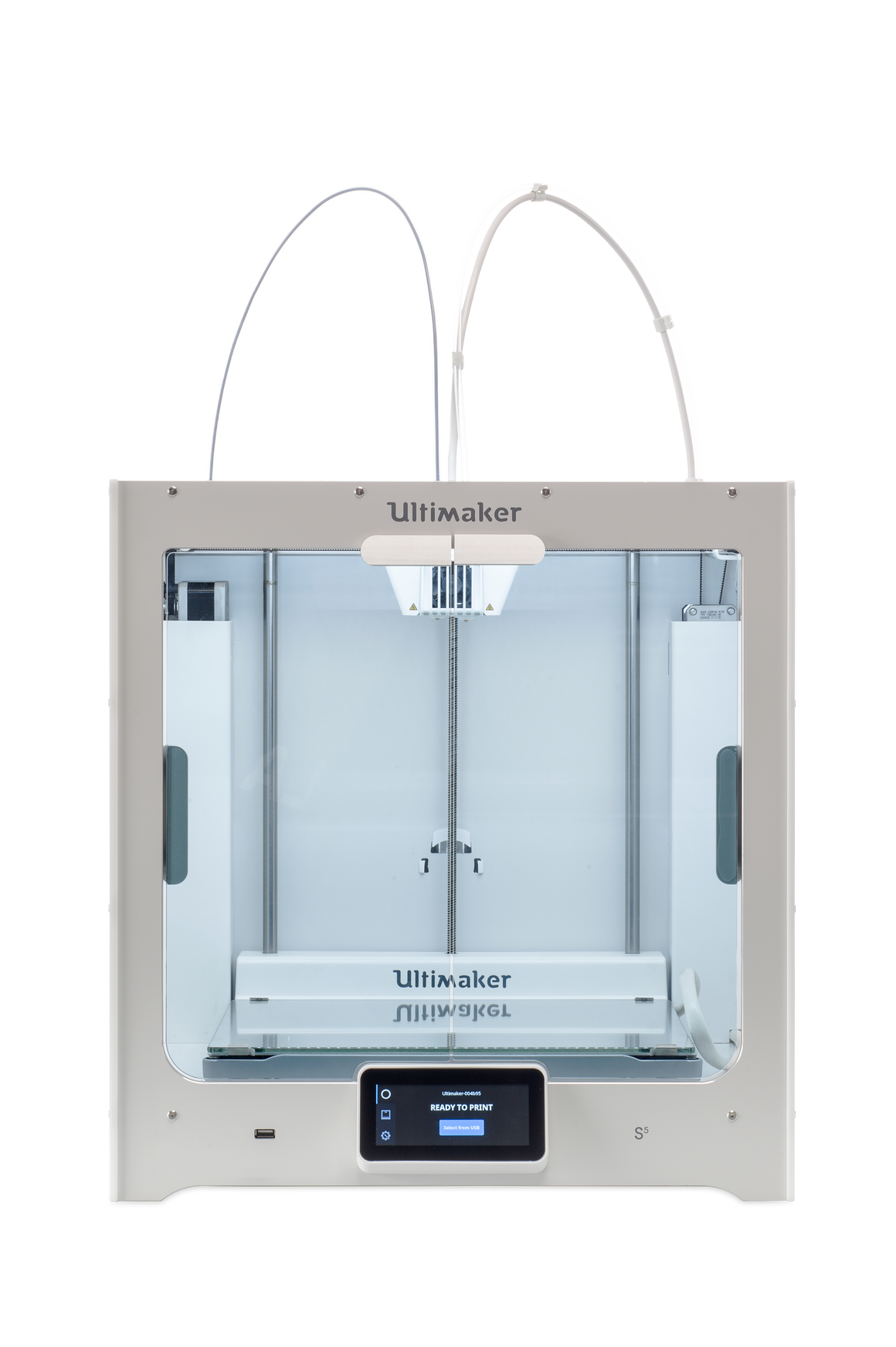

An end-to-end application solution, UltiMaker Factor 4 is tailored for the development, production, and full-confidence deployment of process-critical tools and machine components. Factor 4 keeps operations running, simplifying processes in factories, and reducing human-triggered variabilities. It streamlines factory floor operations with its large effective build volume, direct dual material extrusion, and onboard print process reporting to achieve unrivaled predictability and minimal variance

Built For The Factory Floor

The UltiMaker Factor 4 redefines 3D printing on the manufacturing floor. Its spacious triple-insulated build chamber allows you to utilize every millimeter of the build plate with direct drive dual extrusion. Filaments are kept in optimal condition inside the integrated Material handling system. And its robust construction houses a temperature-controlled build volume, ensuring consistent performance in various operation settings. The UltiMaker Factor 4 is a seamless and powerful addition to any production workflow.

3D printing reliability and repeatability.

Achieving a print success rate above 95%*, the reliability of UltiMaker Factor 4 is anchored in a PEI-coated flexible build plate for superior adhesion and its precise automatic inductive bed leveling for perfect first layers. Its powerful print head moves with incredible accuracy at micro steps down to less than 0.2 mm. This ensures consistency not just on one machine but across an entire fleet, making UltiMaker Factor 4 capable of producing validated parts with uniform mechanical properties vital for multi-location manufacturing. After each 3D print, a comprehensive onboard report simplifies validation and quality assurance before parts are deployed, proving the UltiMaker Factor 4 to be a powerful tool for any operation prioritizing uptime, accuracy, and repeatability in their 3D printing processes. *95% print success rate tested using UltiMaker PLA, Tough PLA, PETG, PET CF, and PPS CF.

Achieve more with FDM 3D printing.

The UltiMaker Factor 4 expands the range of high-performance 3D printing materials. Replace low load-bearing steel and aluminum parts with UltiMaker PPS-CF. Or create gaskets and seals with flexible materials down to Shore 70A. The H-bridge gantry and direct drive extrusion head, which enable rapid dual material printing, will accelerate your production. High-temperature capabilities up to 340 °C using the HT print core, a temperature controlled build volume, and a heated bed up to 120 °C, ensure consistent quality in demanding materials. And all this with seamless software integration with Cura and compatibility with major CAD platforms.

A future-proof investment.

When it's possible to 3D print so many high-value parts and tools with UltiMaker Factor 4, achieving ROI within 12 to 18 months is easy. UltiMaker's commitment to continuous improvement means regular updates that enhance your UltiMaker Factor 4's capabilities over time, backed by dual processors ready for future enhancements. Its modular design ensures easy serviceability and minimal downtime, with global support for swift part replacements. True to UltiMaker's ethos, the UltiMaker Factor 4 remains an open system, allowing for your choice of engineering materials, grounded in over a decade of dedication to innovation and accessibility in the 3D printing industry.

- Technology: Fused deposition modeling (FDM)

- Extrusion System: Dual-extrusion, direct drive print head with unique auto-nozzle lifting system and swappable print cores

-

Build Volume: Single material printing: 330 x 240 x 300 mm (13 x 9.4 x 11.8 in)

Dual material printing: 330 x 240 x 300 mm (13 x 9.4 x 11.8 in) - Filament Diameter: 2.85 mm

-

Print Profiles Availability: 14+ UltiMaker materials

250+ UltiMaker Marketplace materials - Dimensional Accuracy: ± 0.2 mm ± 0.2 % feature nominal length

- XYZ resolution: 6.25, 7.8, 2.5 micron

- Homing sensor: Optical

- Build plate: PEI-coated flexible build plate

- Build plate temperature: Up to 120 °C (248 °F)

-

Build volume temperature: Actively controlled up to 70 °C(158 °F) with nozzle plane temperature uniformity within:

± 3 °C (5.4 °F) for temperatures < 50 °C (122 °F)

± 5 °C (9 °F) for temperatures < 70 °C (158 °F) - Extrusion flow: Closed loop flow compensation

-

Max. extrusion temperature: 280 °C (536 °F): Print core AA, BB, DD

300 °C (572 °F): Print core CC

340 °C (644 °F): Print core HT - Closed loop fans: Air filtering fan, air recirculation fans, print cooling fans, print core cooling fan

-

Compatible print cores: Print core AA (0.25 mm, 0.4 mm, 0.8 mm)

Print core BB (0.4 mm, 0.8 mm)

Print core CC (0.4 mm, 0.6 mm)

Print core DD (0.4 mm) – available in selected regions

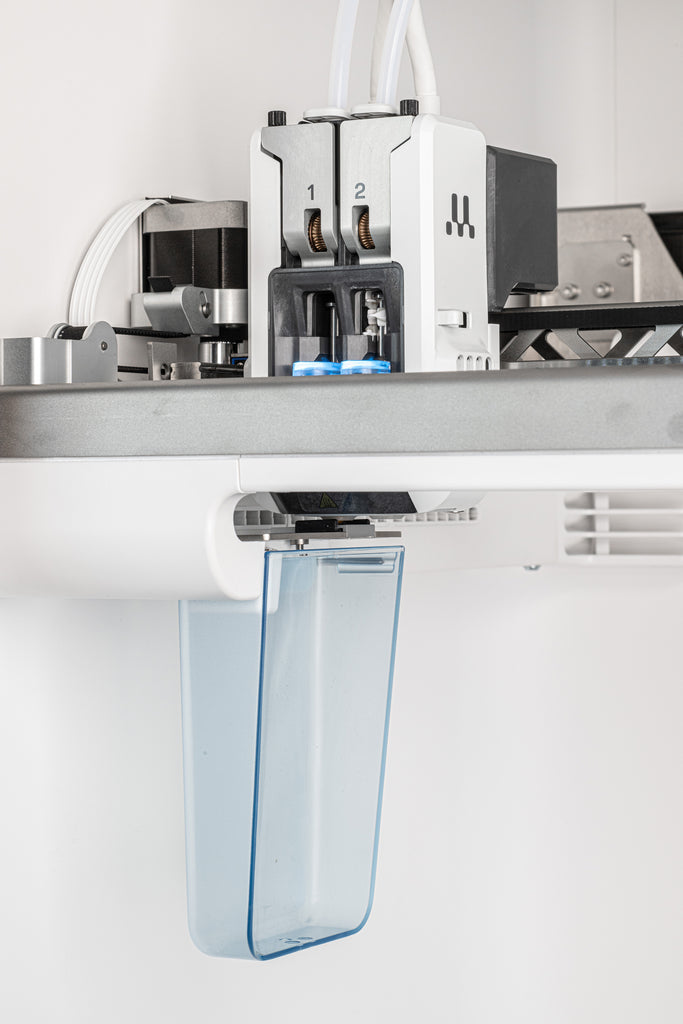

Print core HT (0.6 mm) - Material handling system capacity: 6 bays with NFC recognition (max. 1 kg spool size)

- Material handling system humidity control: Average relative humidity < 15 % in all operational conditions

- Microparticulate filtration system: HEPA H13

- Emission rate (UFP & VOC): UltiMaker filaments below limits listed in UL-2904

- Monitoring: HDR (high dynamic range) 1920 x 1080 px HD camera

- Display: 7-inch touchscreen (resolution 1024 x 600 px)

- Connectivity: Wi-Fi 2.4 & 5 GHz: IEEE 802.11a/b/g/n/ac - LAN: Gigabit Ethernet - USB: 2.0

- System on module: NXP i.MX8 Mini Quad (4 x 1.8 GHz), ARM Cortex-A53, 2 GB LPDDR 4 16 GB eMMC

- Real time controller: i.MX RT1064, Arm Cortex-M7 600 MHz, 1 MB SRAM

- Power requirement: 100 – 240 V AC, 50 – 60 Hz max., 6A

- Dimensions: 695 x 605 x 1287 mm (27.5 x 24 x 51 in)

- Weight: 120 kg (265 lbs)

- Shipping dimensions: 760 x 800 x 1587 mm (30 x 31.5 x 62.5 in)

- Shipping weight: 137 kg (309 lbs)

- Operating sound: < 50 dBA in operation

-

Operating environment: Operating: Temperature: 18 °C – 30 ºC (64 – 86 °F), humidity: 30 – 70% RH

Storage: Temperature: 5 °C – 40 ºC (41 – 104 °F), humidity: 20 – 90% RH

- Print job preparation: UltiMaker Cura 5.7.1 or newer

- Print job management: UltiMaker Digital Factory

-

File types supported: UltiMaker Cura: STL, OBJ, 3MF

Printable formats: G, GCODE, UFP, STEP -

System requirement: Windows 7 (64-bit)

Mac OS X 10.12

OpenGL 2.1

4 GB RAM (8 GB recommended) - Print process reporting: Supported

-

Security: Active firewall

PIN code settings protection

- Warranty period: 12 months limited warranty

- Certifications: For a detailed list of certifications visit ultimaker.com/factor4

- Safety features: Red stop button immediately stops motion and heat sources Open door sensor pauses motion and extrusion

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.