UltiMaker Essentials

Enterprise-grade 3D printing software empowers your teams to scale 3D printing innovation across your organization. UltiMaker Essentials is included with all UltiMaker Printers.

- UltiMaker Cura Enterprise

- Security-assessed software

- User access management

- Associate level e-learning

Whatever the size of your organization, there is a perfect plan for you. Learn More

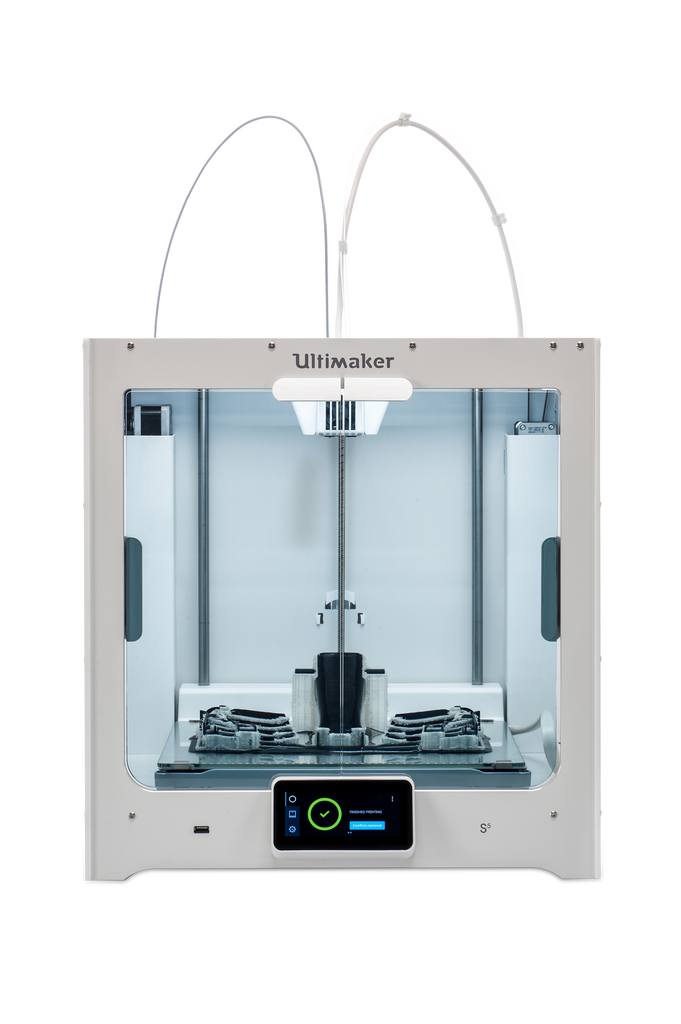

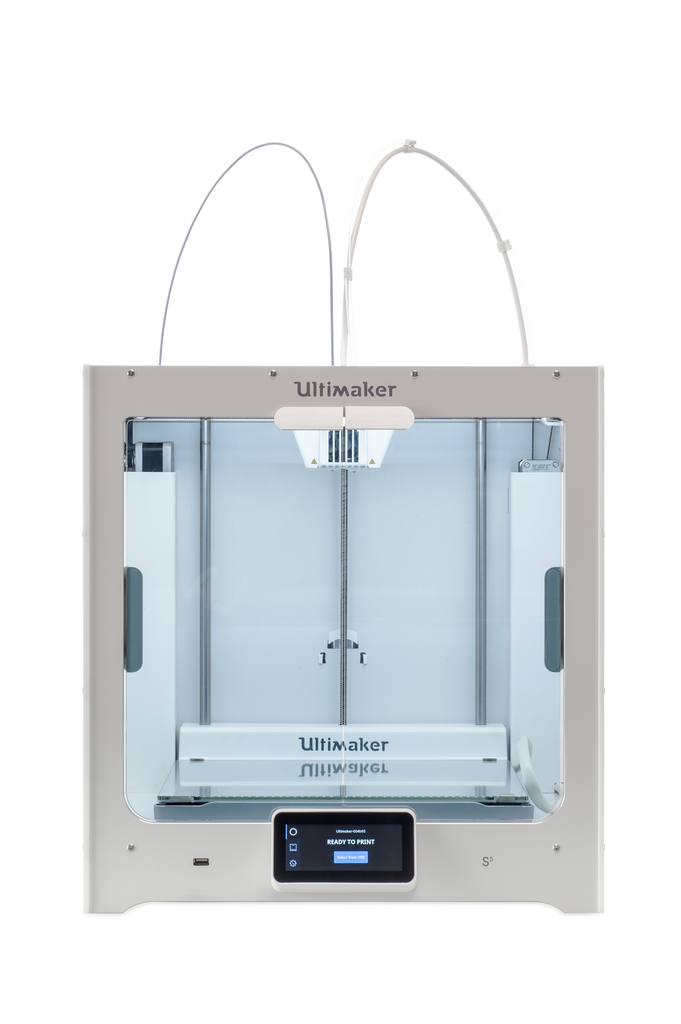

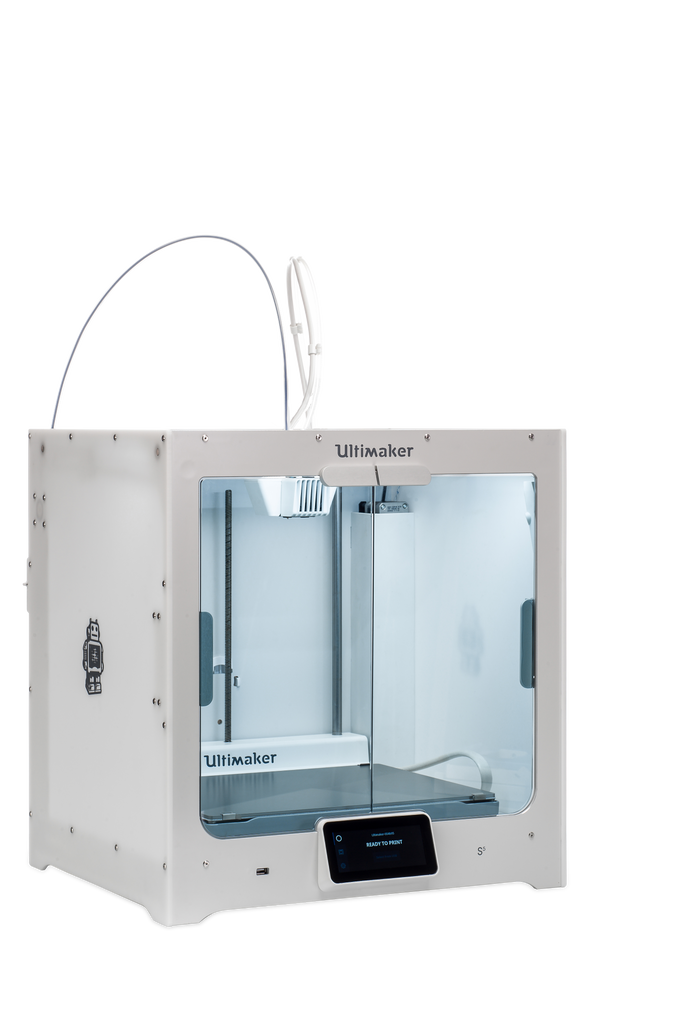

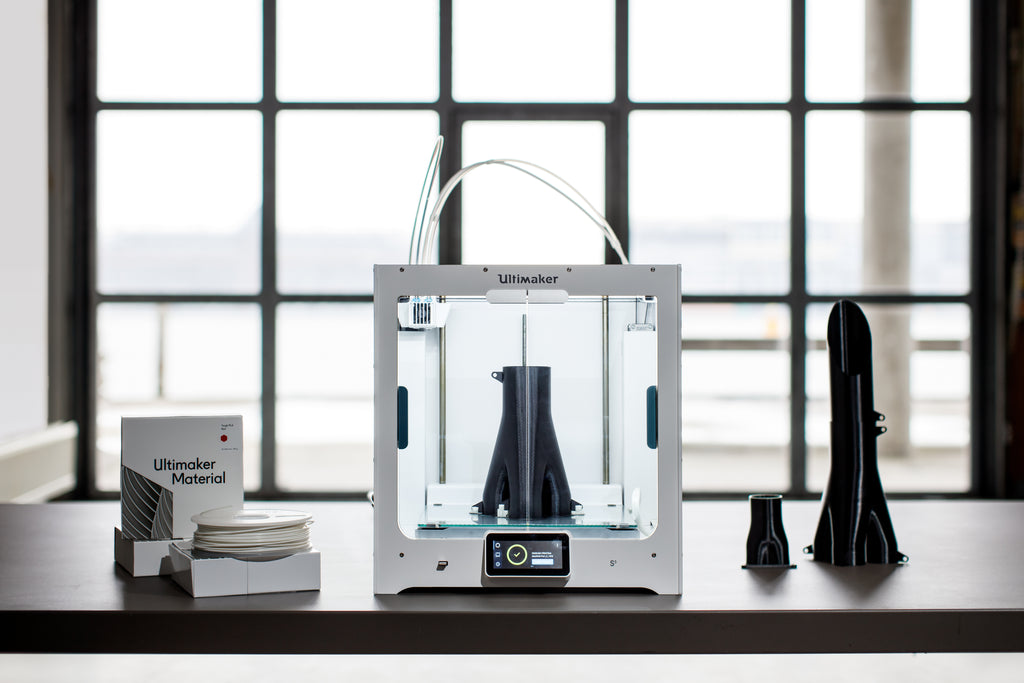

The UltiMaker S5 Studio is UltiMaker's most advanced 3D printer yet.

Designed for your home or office, the UltiMaker S5 is a powerful, reliable and versatile 3D printer that delivers industrial-class results.

Professionals all over the world discovered that the UltiMaker 3 is a powerful, cost-effective solution to streamline their design and prototyping processes and take on more control. Building on the capabilities of the UltiMaker 3 and the feedback of the community, the UltiMaker S5 Studio adds enhanced performance with a larger build volume, improved ease of use, and unrivaled reliability.

- Large Build Volume of 330 x 240 x 300 mm (13 x 9.4 x 11.8")

- Printer Size: 495 x 585 x 780 mm (19.5 x 23 x 30.7")

- Layer resolution down to 20 micron

- Print temperature up to 280 °C

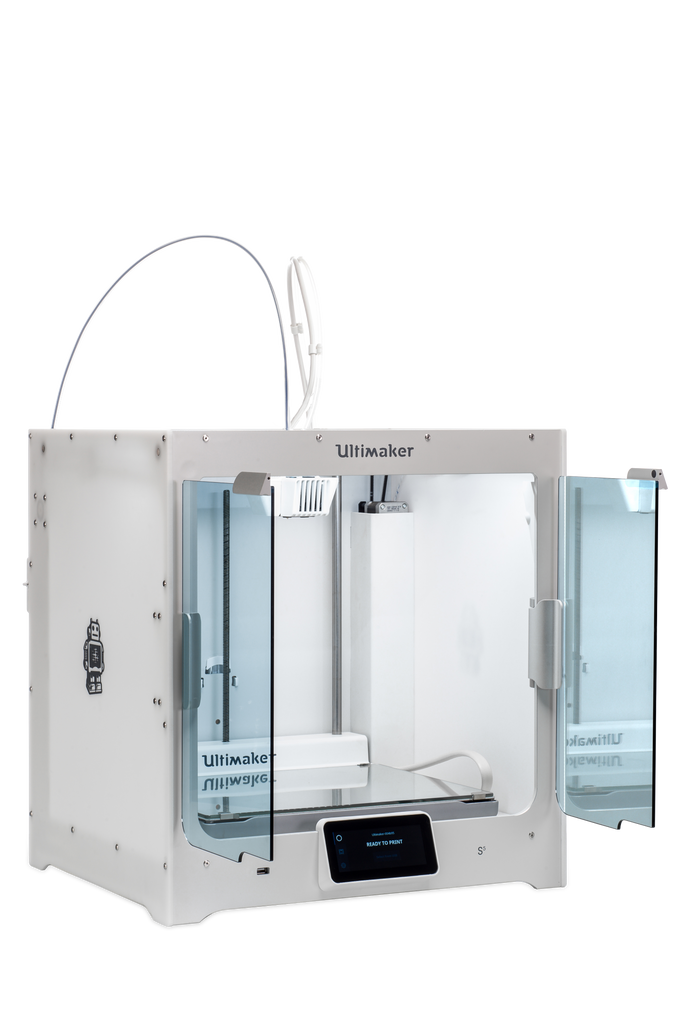

- Glass doors to control airflow

- Dual extrusion with a soluble support material

- Swappable print cores

- Heated build plate with active leveling

- Touch display

- UltiMaker S5 Studio 3D Printer

- 3 Print Cores Included:

2 x AA Build Material Core and 1 x BB Support Material Core - 1 Glass Bed

- 750gr. Spool of Tough PLA and 750gr Spool of PVA Dissolvable Support

- USB key, glue stick, grease, hex wrenches, cables

- Cura, our award-winning print preparation software

- Powerful UltiMaker app

- A calibration card to level the build plate

- Comprehensive 12 month warranty

- Lifetime expert support from Shop3D.ca

- An active global community of makers

- Auto Bed Leveling & Optimized adhesion

- Dual extrusion

- Swappable print cores

- Optimized Cura material profiles

- EEPROM print core chip

- USB port

- Wi-Fi / LAN

- Live camera

- Cura Connect

- UltiMaker App

- Reduce Iteration Time: Give your engineers the ability to iterate every day and improve on their designs.

- Control Prototyping Costs: Inexpensive but high-quality prints allow functional testing in prototyping.

- On-Demand Tooling: Create Jigs, tools, and fixtures that are functional and custom built right on the factory floor.

- Industry standard materials: The S5 has profiles you can load from Dupont, BASF, Clariant and Owen’s Corning.

- Spare Parts on Demand: Never be without the parts you need waiting for a delivery from suppliers, let the S5 work for you.

- End of arm tooling: Create custom tool ends that are no longer proprietary to your assembly line.

Please contact our sales team if you are not sure if the UltiMaker S5 is right for you.

Auto bed leveling

- Optimized adhesion. Prior to printing, your UltiMaker will run through an auto bed leveling to ensure optimal first layer adhesion. The system is designed ensure quality prints for any level of technical experience on a 3D printer.

The print head

- Dual extrusion. UltiMaker's Dual Extrusion technology enables you to print in two materials or colours. Nylon, CPE or PLA in conjunction with water-soluble PVA support material opens up a world of complex and technical models otherwise impossible on a single extrusion printer. Once your print is complete, simply dissolve away the support in water to leave behind your print with amazing surface finish.

- Swappable print cores. Faster print core changes mean higher uptime and easier maintenance. The print cores have built-in EEPROM chips for auto-detection of materials to minimize downtime during configuration. Simply swap out the print cores when switching between build materials and support materials to suit your project needs.

Superior 3D printing experience

- Optimized Cura material profiles. The UltiMaker S5 supports a full portfolio of UltiMaker materials such as ABS, CPE+, Nylon, and TPU 95A.

- Tough PLA. The newest addition to UltiMaker's material line up is Tough PLA, which is included with each UltiMaker S5. Tough PLA shares mechanical properties similar to ABS, giving it high impact strength and stiffness but the same easy of use as PLA, making it the perfect material for large functional prototypes, tooling or manufacturing aids.

- EEPROM print core chip. The EEPROM chip in the print core memorizes the size and type of your nozzle, notifies you in case of misuse and, as a result, helps achieve higher print success rates.

Simple controls and connectivity

- USB port. Enjoy standalone printing using a USB stick.

- Wi-Fi / LAN. Send your print project quickly and easily to your UltiMaker S5 Studio via Cura.

- Live camera. Monitor every stage of your 3D printing project remotely by simply connecting to your UltiMaker S5’s Wi-Fi network.

- Cura Connect. Scale up your operations with confidence with Cura Connect giving you the power to queue jobs and manage multiple UltiMaker S5 and UltiMaker 3 printers. The result? Optimized workflow and exceptional control.

- UltiMaker App. Available on Google Play and the App store. The UltiMaker app gives you mobile access to overview each running job. Now you'll be able to monitor and manage printers, and receive notifications where you are - even if its outside your local network.

The heated build plate

Dual geared feeders

Geared feeders exert more force on the filament, and also eliminate heat exposure from the motor. Change your 3D printing materials with ease, select the correct pressure with a push on a button, and use the lever function to manually insert or remove a filament. More control means more successful, reliable and durable 3D print results, without compromise.

The UltiMaker S5's Dual geared feeders now come equipped with a flow censor to prevent failures when you run out of materials.

The new hardened feeder wheel has also been added for composite materials.

Industrial-grade materials

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.