Please see information from ForwardAM on the new processing service for 316L and 17-4PH Metal Filament Debinding and Sintering. Due to this change from the manufacturer, Shop3D is no longer selling the sintering coupons, please contact DSH directly for sintering options.

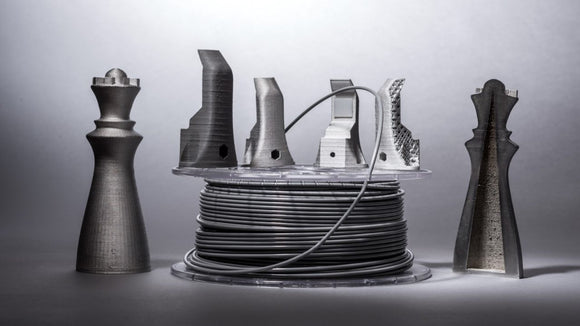

This filament is considered an expert user level filament. Successfully printing, debinding and sintering requires very specific workflows that must be followed without exception. Any deviation can damage your printer, your finished print or the debinding equipment from our sintering partner. Exceptional care must be taken into account during printing and transport of green parts. Not all print geometries may be successful in the sintering process. Pre-planning and post-processing will increase the chances of success. We highly encourage booking a free appointment with our application engineers to discuss your application for 17-4PH. Please be sure to reference all print guidelines from Forward AM prior to the consultation. No returns are accepted for opened filament or print or sintered failures.

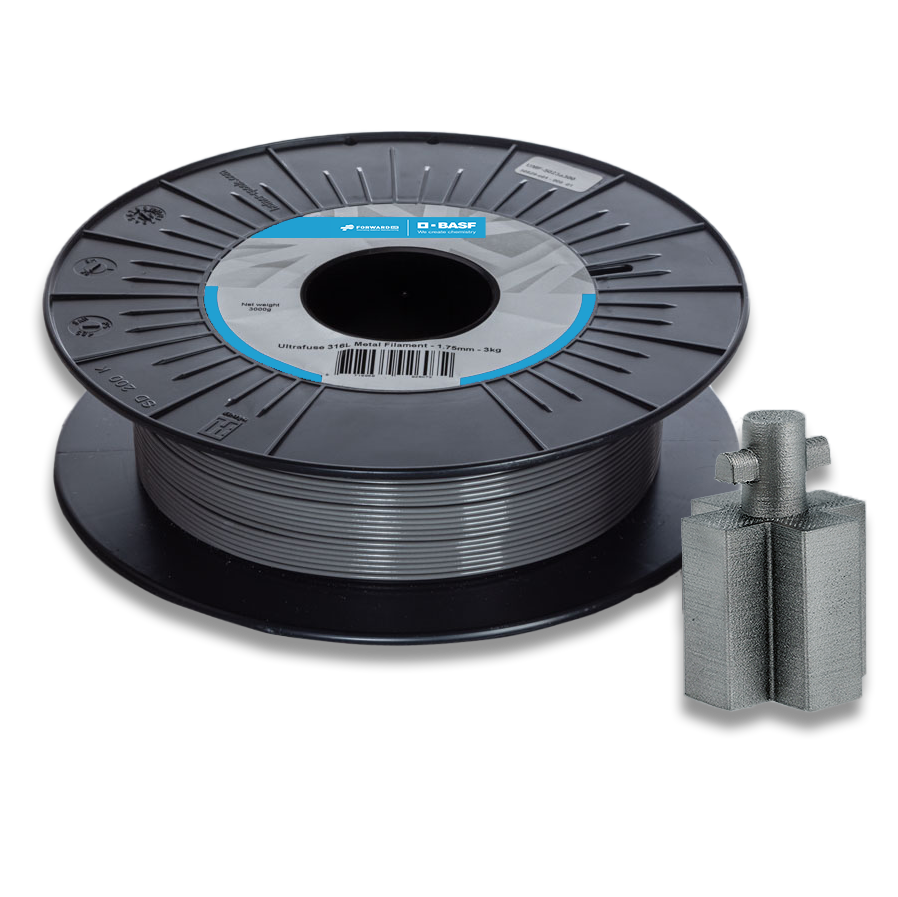

Designed for ultimate ease of handling on conventional Fused Filament Fabrication 3D printers. Ultrafuse® 17-4 PH is a filament for the production of metal components in 17-4 stainless steel on standard Fused Filament Fabrication (FFF) printers. This stainless steel can be fully heat treated to high levels of strength and hardness. It is therefore ideal for Petrochemistry, Aerospace, the Automotive and the Medical Industry. Parts printed with our metal-polymer composite filament Ultrafuse® 17-4 PH obtain their final properties through a catalytic debinding and sintering process known from traditional Metal Injection Molding.

- Produces parts of stainless-steel type 17-4PH

- Easy handling

- Uniform particle distribution enhancing mechanical properties

- OSHA-friendly processing

- High filament flexibility allows funneling through complex idler pulleys and guide-roller filament transportation systems in any printer

- Compatible with both Bowden and direct drive extruders through the use of a non-slip outer surface

- Shrinkage during sintering requires adjustment during part design

- Nozzle Temperature: 230 - 250°C

- Bed Temperature: 90 - 120°C

- Bed Material: Glass + approved glues* / polyimide tape (*Dimafix® suggested)

- Nozzle Diameter: ≥ 0.4 mm

- Print Speed: 15 – 50 mm/s

- Tooling

- Jigs & Fixtures

- Series production

- Functional parts and prototypes

To print the best possible way with Forward AM filaments

Forward AM provides you with a large range of printing profiles for their materials based on different well-known printer manufacturers like Ultimaker, Raise3D and BCN3D

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.