Create high quality molds and parts in minutes

With The Mayku Multiplier, you can create high-quality molds and parts in just minutes. The industrial power of the machine allows you to scale up your project at record speed—and gives you full control over every aspect of production.

Make fully transparent prototypes, detailed final parts and cast complex objects with flexible molds. Create parts with a high level of detail and accuracy similar to injection molding at a fraction of the cost.

Mayku Multiplier tail-light production workflow

This document details the entirety of the workflow involved for producing a motorcycle tail light casing using a combination of 3D printing, pressure forming and cutting.

Mayku Multiplier protective camera enclosure production workflow

This document details the entirety of the workflow involved for producing a protective camera enclosure using a combination of 3D printing, pressure forming and cutting.

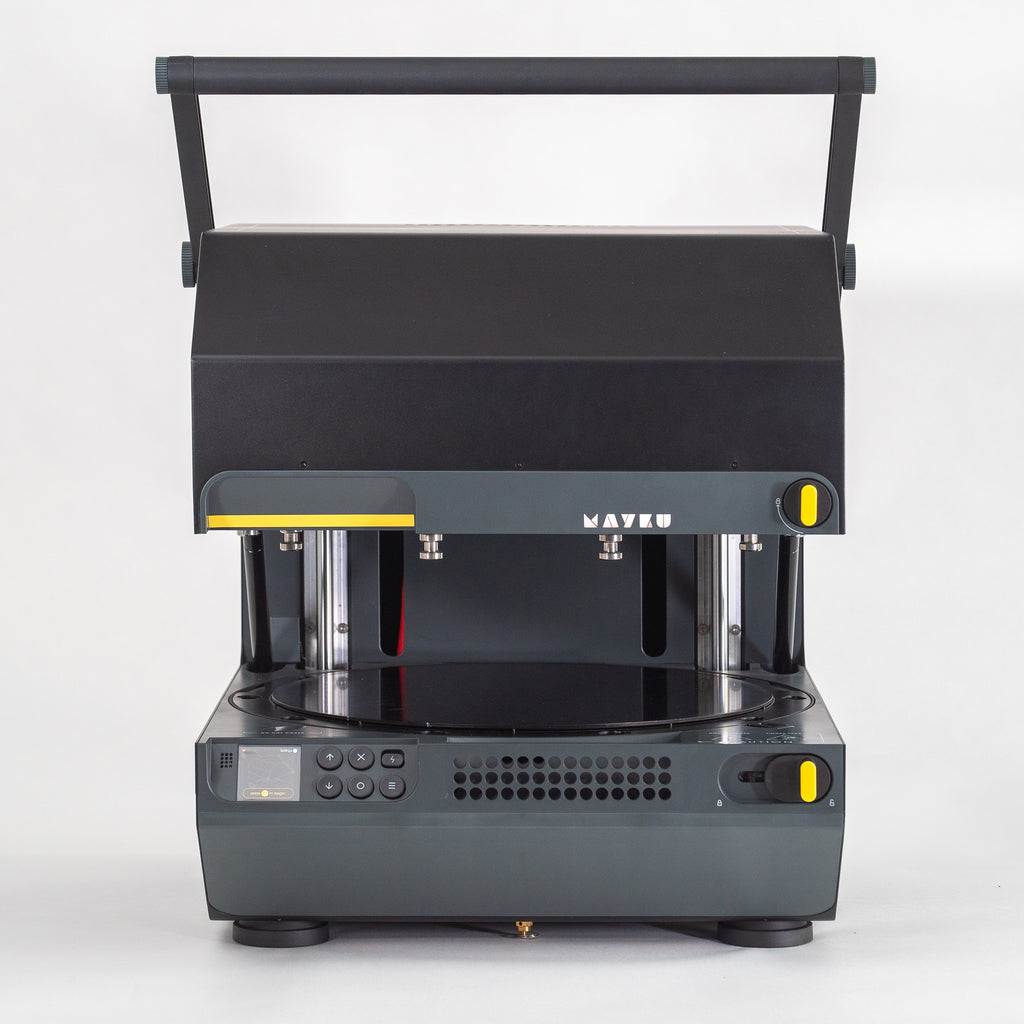

The Mayku Multiplier

Take Full Control

Create what is needed, where and when it's needed.

Industrial Grade Performance

Over 5 tonnes of force ensures factory-level quality and detail.

Produce in minutes

Eliminate unnecessary lead times. Create molds and parts in under 5 minutes.

Machine Dimensions

- Length: 585mm

- Width: 515mm

- Height: 420mm

- Weight: 67.5kg

- Forming Area: 400mm (W) x 160mm (H)

- Max template volume: 3500cm3 / 214in3

Technical Data

- Maximum Pressure: 4.1 bar/60psi (Dome), 12 Bar/175 psi (tank)

- Input: 110-240v, 12A/6A (Single Phase)

- Max Power: 1500W

- Frequency Band: 2.4GHz

- Operating / storage temperature: +5 to +40C

- LCD Resolution: 720x720

- Connectivity: WiFi

- 400mm (W) x 160mm (H) circular forming area

- Up to 60 psi (4 Bar) of forming pressure

- Up to 5mm sheet thickness

- Automatic sheet leveling (no plastic droop)

- Precision IR sensor for plastic temperature control

- 8 independent/redundant safety features

- WiFi updateable firmware for new features/materials

- In-built self testing, maintenance for ease of use

- In-built air outlet for tools and accessories

- The Mayku Multiplier

- Power Cable

- Activation Leaflet

- Tool kit

- First Make Kit (Includes: 2x PETG, 2x HIPS, 2x EVA, a sample template and information booklet)

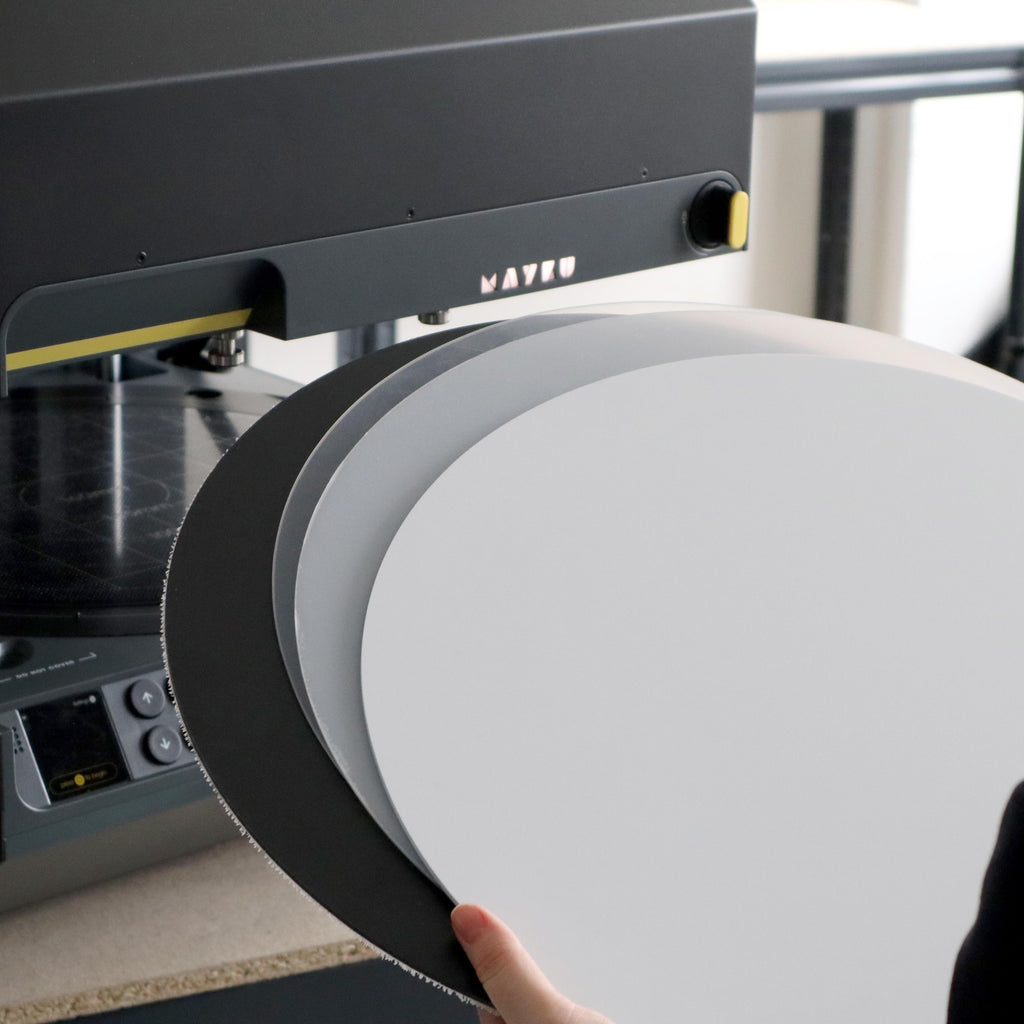

- PETG (Transparent and food safe)

- HIPS (Opaque for casings)

- EVA (Flexible for complex shapes)

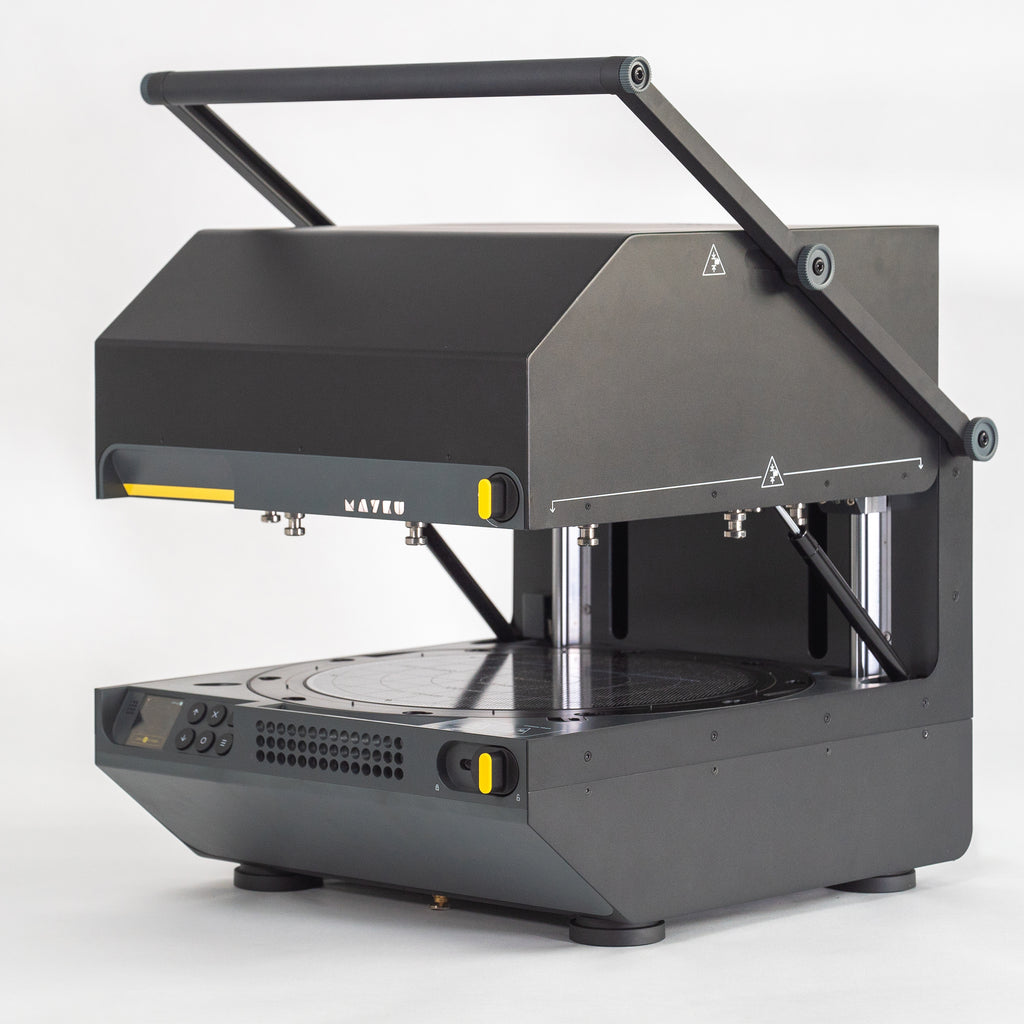

60 psi creating up to 5 tonnes of force

Create accurate parts with incredible high levels of detail by unlocking more than 4 times the power of vacuum forming.

Deliver working temperatures in minutes

Heat materials up to 200 C in under two minutes. The smart levelling system controls pressure during the heating process to keep materials completely horizontal, ensuring consistency of result.

High power made acccessible

Industrial-grade components and smart features deliver a safe and reliable pressure forming process that allows you to focus on the perfect output for your application.

Create large parts or multiple smaller ones

A 400mm circular forming and a vertical allowance of up to 160mm provides you with full flexibility and rapid turnaround times.

Improved functionality over time

With Wi-Fi connectivity and seamless firmware updates, the Multiplier grow richer over time with new features and expanding maerial possibilities.

Accessible for anyone

Our expanding library of Mayku materials comes in multiple thicknesses and with tested profiles to give you the most reliable, repeatable results. Every time.

The Multiplier's screen guides you from start to finish, offering an easy, guided experience.

Tune the Multiplier to perfectly form your choice of material. With custom mode, users cant access precise control over temperature, material profiles, and save calibrated settings per material choice.

Reducing machine downtime by manufacturing essential covers in-house

The Mayku Multiplier, food molds, and 10-times-faster part validation

Pressure forming, part validation, and a faster time to market

Students access pressure forming technology on the benchtop at Bristol University

Rapidly creating high detail custom molds with Forma Moulds

Reducing plastic waste through prototyping highly detailed parts

Designing the Multiplier with Teenage Engineering

Teaching faster, cost effective and accessible prosthetic molding techniques

Utilizing The Mayku Multiplier For The Dental Industry

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.