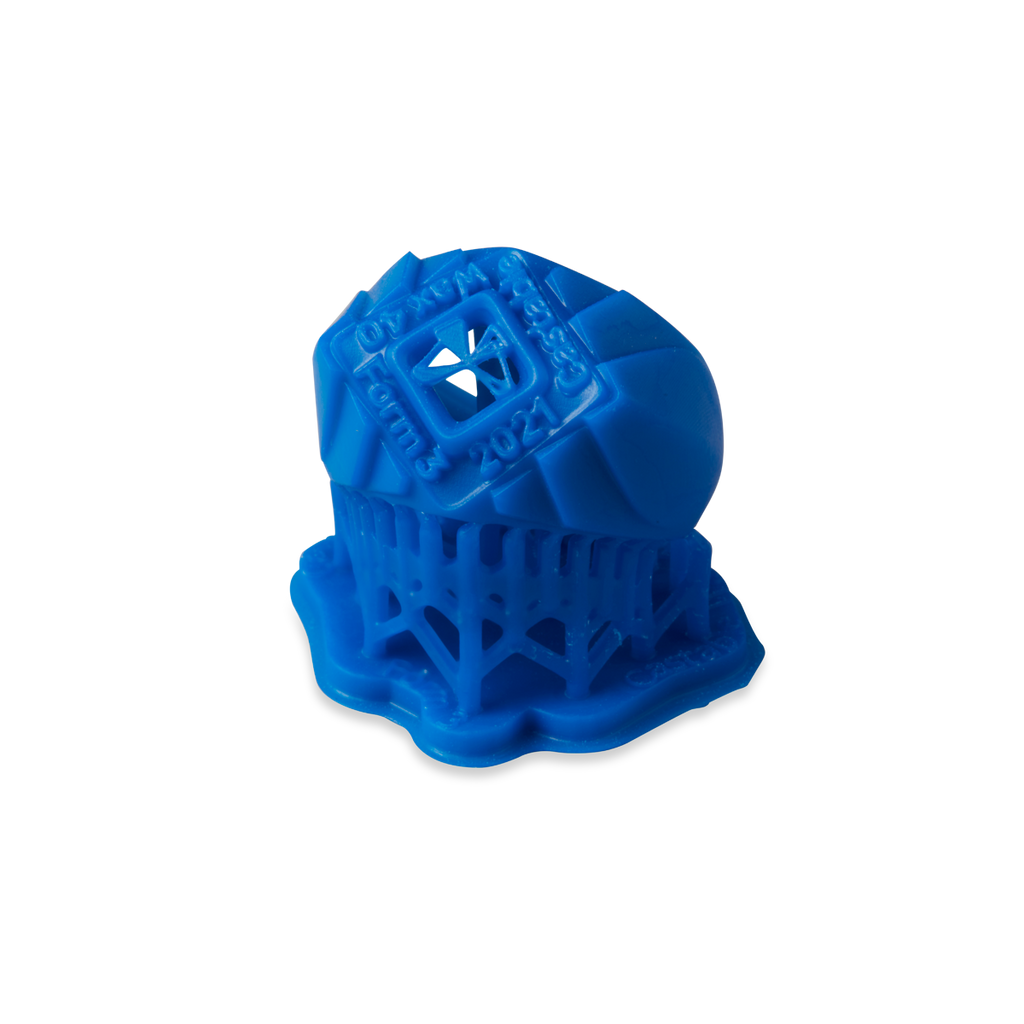

From intricate bridal jewelry to large demanding pieces, Castable Wax 40 Resin offers the easiest workflow on the market for 3D printing and casting challenging, highly detailed designs. With a 40% wax fill and low expansion, Castable Wax 40 Resin supports a wide range of lost wax casting conditions and is compatible with leading gypsum investments, producing superior results for jewelers who outsource casting. Castable Wax 40 Resin creates beautiful 3D printed jewelry pieces that burn out cleanly.

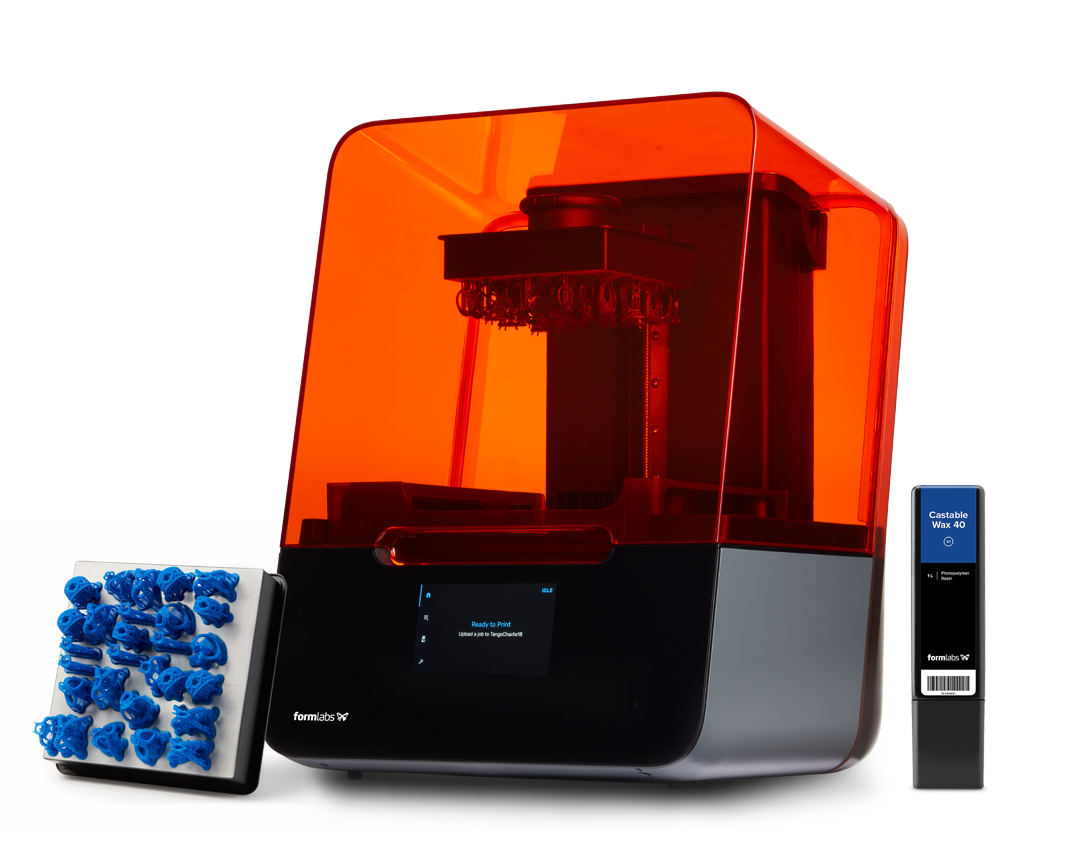

Castable Wax 40 Resin makes it easy to transition from traditional wax workflows to a digital 3D printing workflow

1. Easy to Cast: Castable Wax 40 Resin supports a wide range of lost wax casting conditions and is compatible with leading gypsum investments.

2. Design Flexibility: Create heavy jewelry and difficult-to-cast features with ease. Castable Wax 40 Resin will minimize common expansion related defects.

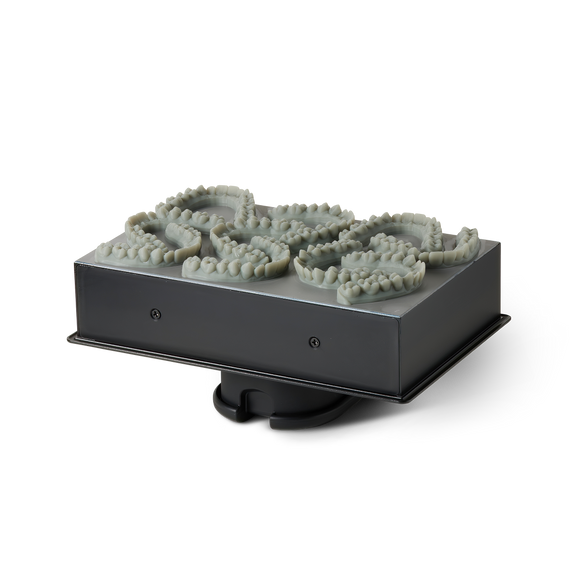

3. Supported by a Complete Ecosystem: With unmatched ease of use and groundbreaking materials like Castable Wax 40 resin, you can print casting patterns, mold masters, and prototypes all with the Form 3.

Reliably manufacture production-quality jewelry your clients will love with Castable Wax 40 Resin, a breakthrough jewelry resin with industry leading castability. Heavy jewelry and difficult to cast features including engraved text, stone holes, and channels resolve stunningly with Castable Wax 40 Resin.

- Heavy signet and class rings

- Pendants and medallions

- Custom bridal jewelry

Burnout Properties

|

Temperature @ 5% Mass Loss |

249 °C |

|

Ash content (TGA) |

0.0 - 0.1 % |

Burnout Schedule & an Introduction to Casting for 3D Printed Jewelry Patterns

|

Form Wash Settings Duration: 5 min (x2)

Notes: Wash Castable Wax 40 prints in isopropyl alcohol (IPA) for 5 minutes. Rinse for 5 minutes in a second, cleaner IPA bath to eliminate any remaining uncured material. Fully dry parts with compressed air. Do not use TPM to wash.

|

Optional Form Cure Settings Duration: 30 min Temperature: No heat

Notes: Post-curing is not required for bulky Castable Wax 40 prints, but can increase handling strength if desired. Cure parts for up to 30 minutes with no heat. |

Request a Free Custom Quote

Use our easy tool to build a customized quote.

Request a Custom 3D Print Sample

Let us prove that the technology will work for your use case.

Speak with an Expert

Talk 1:1 with an expert. Tell us your challenges and our team will help you find the best solutions to meet your unique needs.