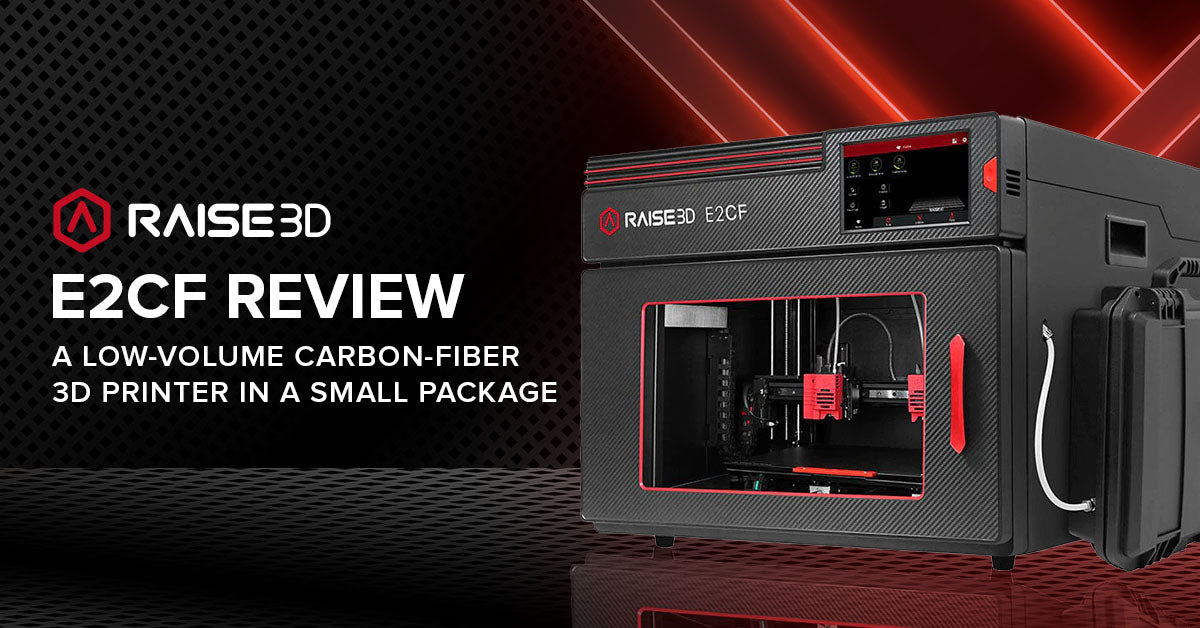

Raise3D E2CF Review - A Low-Volume Carbon-Fiber 3D Printer in a Small Package

November 03, 2022

Aniwaa recently took a close look at the Raise3D E2CF, a small and affordable 3D printer designed to make small batches of strong, composite parts. Their goal was to put the machine to the test, to find out one thing: Is the E2CF true to it's word?

We're turning from Raise3D's flagship Pro 3 series of large-format 3D printers to look at the E2CF from the E2 series. Whereas the original E2 is a good choice for standard materials, the E2CF is specifically designed to 3D print composites like carbon fibre (CF) and glass fibre (GF) materials.

Both 3D printers have the same sturdy frame, dimensions, Easy Swap IDEX system, flexplate, HEPA filter, onboard camera, and a slew of other features that make Raise3D's professional-grade machines a breeze to use.

So, what distinguishes the E2CF and makes it so well-suited to composites and their enticing strength-to-weight ratios?

To combat the abrasiveness of composite materials, which would quickly damage a standard brass nozzle, the Raise3D team outfitted the E2CF with tough, silicon carbide nozzles. The extruders on this printer have reinforced gears to push the filament through the nozzles. Raise3D also mentions adding a new "auxiliary process" to improve the printer's automatic nozzle height calibration accuracy, resulting in better first layers and support adhesion.

Another important aspect of the E2CF's value proposition is continuous, dependable 3D printing for small batch production. It comes with two filament dry boxes, as opposed to the E2, to protect the materials from dust and humidity. Keeping the filaments dry, along with ideaMaker's thoroughly tested and authorised material profiles, contributes to the E2CF's ability to work around the clock.

It should be noted that the E2CF can only 3D print with Raise3D-approved materials. On the plus side, Raise3D is able to guarantee users such high quality and reliability by controlling exactly which materials can go into the E2CF. After kilos of filament and hours of printing, they create material profiles for each new filament to provide the perfect parameter recipes for successful prints. On the negative side, the inability to print basic PLA or other non-certified third-party filaments can be frustrating.

The E2CF only works with composite filaments, which are thermoplastics reinforced with short strands of materials like carbon fibre or glass fibre. These composite materials are appealing because they have superior mechanical properties when compared to their "pure" thermoplastic counterparts, and they also have a smoother finish and better layer adhesion.

Raise3D's authorized materials portfolio includes their proprietary PA12 CF, PPA CF, and PPA GF (as well as support materials), and the team has recently released more bespoke filaments. These 32 third-party filaments include low-cost options like eSun and Polymaker's reinforced filaments, as well as premium brands like BASF, Jabil, Kimya, and LEHVOSS.

While the E2CF is not the first printer to feature IDEX (Independent Dual Extruders), it is one of the few carbon-fiber-optimized printers that does. This is a significant benefit that allows users to more than double their production rates for composite parts that do not require support structures.

Mirror mode and Duplication mode are the two ways to speed up prints with independent dual extrusion (IDEX).

In Mirror Mode, each nozzle prints one half of the same object from opposite sides. If you're printing a large part that doesn't require support material, this is a great way to reduce production time.

Another way to cut total print time by up to 50% is to use Duplication Mode. The two printheads perform the same movements in order to print the same parts. It's a huge time saver, and when combined with the E2CF's dependability, it makes it an ideal partner for small batch production runs.

First and foremost, if you use Mirror or Duplication mode for a print, you cannot use breakaway support material. You can construct support structures out of the main material, but they will be difficult to remove and will leave marks.

Rafts are also out of the question. Composites are extremely strong, and the layers adhere to each other extremely well. Aniwaa had included rafts on one batch of PA12CF parts in Duplication mode and had difficulty removing them! They succeeded, but at the expense of damaging the first layers. It is recommended to spread a new layer of Magigoo rather than using rafts when printing in only one material (without breakaway support). Aniwaa had no problems while using this technique.

As a result, the two IDEX modes are extremely beneficial, but only for 3D models with extrusion-friendly overhangs.

Overall, Aniwaa had a positive experience with the E2CF. It produced excellent prints, was simple to operate, and its sleek design was ideal for their office environment.

It's worth noting that the printer heats up quickly, which saves time on maintenance tasks like loading and unloading filaments. This also means a shorter wait until the first layer, which is something every 3D printer operator does to ensure prints start successfully. Aniwaa left the E2CF running unattended for several weekends without incident, with their longest print lasting more than 70 hours.

If you or your company are looking for a cost-effective compromise between a desktop printer and a larger, industrial-grade 3D printer, the E2CF is an excellent choice. As long as you're okay with the limited filament options and treat it properly (i.e., use perfectly dry filament with the correct profiles), you'll be dealing with a dependable workhorse capable of producing batches of strong, carbon-fiber-reinforced parts quickly.

To read the entire comprehensive review from Aniwaa, you can check it out here.

Also in News

Shop3D.ca at ADM Toronto (Advanced Design & Manufacturing Expo)

September 23, 2025

Shop3D.ca, Canada’s leading provider of 3D printing solutions, is proud to announce its participation in the Advanced Design & Manufacturing Expo (ADM), taking place October 21 – October 23, 2025, at the Toronto Congress Centre.

Shop3D.ca Open House: 3D Scanning with the EinScan Rigil

September 22, 2025

Join the Shop3D.ca technical team for an interactive demo of the new EinScan Rigil 3D scanner. Learn the ins and outs of professional 3D scanning, and bring a medium-sized object to scan. You’ll leave with your very own 3D model file—just make sure your item is light enough to handle and can be rotated during scanning.

Shop3D.ca at the Canadian Manufacturing Technology Show (CMTS)

September 10, 2025

Shop3D.ca, Canada’s leading provider of 3D printing solutions, is proud to announce its participation in the Canadian Manufacturing Technology Show (CMTS), taking place September 29 – October 2, 2025, at the Toronto Congress Centre.